Aviation Industry - Cold War

Aviation Chief Designers | |

|---|---|

| Antonov | Oleg Konstantinovich |

| Bartini | Robert Ludvigovich |

| Beriev | Georgy Mikhailovich |

| Ilyushin | Sergey |

| Kamov | Nikolay Ilyich |

| Lavochkin | Semyon Alekseyevich |

| Mikoyan | Artyom |

| Mil | Mikhail Leontyevich |

| Myasistchev | Vladimir Mikhailovich |

| Sukhoi | Pavel Osipovich |

| Tsybin | Pavel Vladimirovich |

| Tupolev | Andrey Nikolayevich |

| Yakovlev | Alexandr Sergeevich |

During the Soviet era Ministry of Aviation Industry [MAP: Ministerstvo Aviatsionnoi Promyshlennosti] supervised over 400 enterprises. Of these former Ministry of Aviation Industry, 15% were lost overnight when Russia shrunk to its present borders. During the 1980s 70% of the output of the ten major airframe design bureaux and the 20 major production factories was for the military. During the 1990s the reduction in military budgets effectivly ended military aircraft procurement. The remaining 30% was civil, for Aeroflot and some foreign airlines, and represented approximately 100+ jet and turboprop airliners and airfreighters per year - plus several hundred helicopters.

During the Soviet era aircraft such as the Tupolev Tu-154 or the Ilyushin Il-62 were transferred from one government department, the Ministry of Aviation Industry (MAI) to another, the Ministry of Civil Aviation (MCA), for a national value of one million roubles (approximately $150,000 at the then [unofficial] rate of exchange widely available). The Ministry of Civil Aviation then allocated it to an Aeroflot unit, which regarded the aircraft as being 'free of charge'. As such, it did not much matter if the aircraft sat, unused, on the ramp for months on end.

By the mid-1960s, the Soviet press reported that repair of existing machine tools occupied 3.5 times as many people as were actually employed in manufacturing new units; that electric motors, during their first year of life, spent 30 to 40 percent of their total working time undergoing repairs; that, at any given time, not less than 40 percent of all vehicles in the Soviet Union were idle, awaiting repairs.

Another dramatic illustration of the progressive deterioration of quality and quality control in the Soviet Union was provided by an item on the television industry. In any normal civilized country, the general experi- ence is that the quality curve of complex products rises from year to year as weaknesses are eliminated and design and methods of manufacture improve. In the Soviet Union the reverse was the case. Thus, a study of television failures during the guarantee period of 6 months after sale revealed that the quality of sets had been deteriorating. In 1960, the percentage of failures during the first 6 months attributable to defective tubes was 47 percent. In 1961 it was 52 percent. And in 1962 it rose to 61 percent.

The Soviet military was impressively equipped, and it had been built up, without regard to cost, by ruthlessly starving virtually every other sector of the Soviet economy. This industry commanded the best equipment, had access to the highest quality materials available, and employed the best qualified technical personnel. High precision measuring equipment, to the limited extent in which it was available to Soviet industry, was concentrated in the factories feeding the defense establishment. Production standards are more rigorous in these factories and inspection procedures are the severest to be found in the Soviet Union. With all of these advantages, the Soviet defense industries had been able to turn out small weapons and artillery and tanks of good design and apparently acceptable quality.

Even in the considerably less sophisticated sphere of aircraft production, their defense industries, despite the many advantages they enjoy, turned in a questionable performance. For example, Khrushchev himself, in his statement of December 13, 1963, before the Communist Party Central Committee, complained that: "Up until recently Soviet aviation industry has been manufacturing aircraft engines with a service life Of 500 hours, while the British engines have a life of 2,200 to 2,500 hours."

Even in the considerably less sophisticated sphere of aircraft production, their defense industries, despite the many advantages they enjoy, turned in a questionable performance. For example, Khrushchev himself, in his statement of December 13, 1963, before the Communist Party Central Committee, complained that: "Up until recently Soviet aviation industry has been manufacturing aircraft engines with a service life Of 500 hours, while the British engines have a life of 2,200 to 2,500 hours."

In addition, there is the fact that the quality of Soviet electronic equipment is so low that the Soviets prefer to trust the safety of their TU-104 and IL-18 airliners to British-made navigation equipment, and that even a Czech-produced Mig-15 fighter which crashed in West Germany was equipped with West German electronic equipment.

To summarize: Instead of catching up with the West, and becoming less dependent on it, Soviet industry seemed to be lagging further and further behind the West and to be growing more dependent on it. This is so because the technological explosion of the 1960s made modern industry more dependent than ever on ultrahigh precision and on the instruments capable of assuring such precision, on rigid standards .of quality control, on sophistication of design and painstaking workmanship. These are precisely the were where the Soviet Union was weakest and where the Soviet system raised the greatest obstacles to progress.

Under Khrushchev he Ministry of the Aviation Industry (MAP) underwent a reorganization, changing its name to the Committee of Aviation Technology. No matter how the organizational boxes are shuffled, the same functions generally continue to be performed by the same people with the same old equipment.

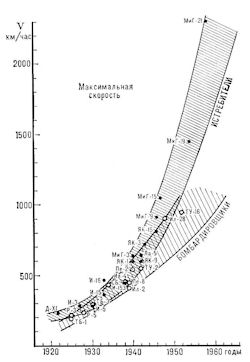

The annual plan which defined the operations of individual enterprises originated with the Politburo, which established the general strategic requirements of the USSR. For example, it determirted that Soviet industry must produce a certain number Of Jet propelled aircraft of a given perfor:mance standard, superior in number and performance to those currently produced by Western nations. These requirements were passed on to the Ministry of Aviation, which determined the earliest dates for the achievement of these production goals. If these requirements called for development of a new plane, aircraft designers in the ministry developed technical specifications and plans and passed them on to the Council of Ministers as specific projects.

The Council of Ministers discussed and approved these projects and established their total cost as well as final completion dates. Total costs were held to include wages and salaries, raw materials, other purchases, and bonuses. The Council of Ministers did not deliberate on the production plans for enterprises engaged in serial production, but only considered key projects such as experimental aircraft.

A project was then returned approved to the Ministry of Aviation, which submitted it to the various aircraft development plants for bids. Such a project, was treated as a contract and the directors of the various plants engaged in aircraft development were forced to compete for it. The directors of the various plants engaged in developing aircraft were called to Moscow, where the terms of the project were read to them. A director was then given a brief period to check on possibilities within his plant before submitting his bid. The plant director who made the best offer in terms of production time and costs usually received the assignment. In other cases, a project was awarded to two development plants, which then carried out parallel operations. In the case of some contracts, this bidding was probably a mere formality, as the projects had definitely been drawn up specifically for [if not by] the "winning" enterprise.

The Soviet economic apparatus had laid down the general rule that a director of an enterprise was never foroced to take an assignment from his supervising ministry, but, rather, was obliged to compete for such projects. The idea was that each person engaged in industry, including plant directors, had to assume a personal obligation and not simply receive an order. It was felt that this principle stimulated efficiency and initiative on the part of plant directors. Failure of a director to obtain orders or contracts for his plant would mean that he would lose his job. The plant could even be closed if it were so inefficient as to be not viable.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|