Bohai Shipbuilding Heavy Industry Co., Ltd [BSHIC]

Bohai Shipyard

Huludao, China

40°43'N 121°00'E

Nuclear-powered attack and ballistic-missile submarines are built at the Huladao shipyard. As one of the principal enterprises subsidiary to China Shipbuilding Industry Corporation, Bohai Shipyard was a large factory engaged in shipbuilding, repairing, steel structure processing, metallurgy equipment and large hydroelectric equipment fabrication and also the official research base for important technical equipment.

Nuclear-powered attack and ballistic-missile submarines are built at the Huladao shipyard. As one of the principal enterprises subsidiary to China Shipbuilding Industry Corporation, Bohai Shipyard was a large factory engaged in shipbuilding, repairing, steel structure processing, metallurgy equipment and large hydroelectric equipment fabrication and also the official research base for important technical equipment.

The shipyard borders on the northern coast of Bohai Gulf and the famous Huludao Port is located in the center of the yard. China's nuclear powered submarines were built at Huludao Naval Base and Shipyard in the northern Bohai Gulf. The first Xia-class SSBN was launched in April 1981, and deployed in January 1989 to the Jianggezhuang Submarine Base [aka Qingdao / Ch'ing-tao], where the nuclear warheads for the JL-1 SLBM are reportedly stored. Chinese media reported in early 2017 that the Bohai shipyard built a large new shipyard plant and ancillary facilities. Due to the construction of the large-span steel girder structure, it required advanced building technology, which some called the new era of "mega-projects". According to media reports, the plant took just less than one year to finish construction. Russia has such a large-span steel structure plant, but now it is inactive. By some reports, Russia said to recover this plant would need at least 3-5 years. China built a new plant in less than 1 year, Russia night need 3-5 years to recover.

United States reconnaissance satellites cannot find details of the construction of nuclear submarines at this facility. Previously China built Type 091 attack submarines and Type 092 strategic nuclear submarines with open dock assembly construction mode. This used only one dock, assembling one nuclear submarine at a time. In this way, the specific number of submarines will be exposed, and US military reconnaissance satellite spying was easy.

China is now the world's leading builder of nuclear powered submarines and has the capacity to build at least four boats simultaneously. State-owned Bohai Shipbuilding Heavy Industry Co., Ltd. (BSHIC) located at Huludao Port in southwestern Liaoning Province on the northern coast of the Bohai Gulf, has built a new plant and ancillary facilities to "mass produce nuclear submarines." State media revealed BSHIC will build the lead ships in China's newest class of nuclear ballistic missile submarine (SSBN) -- the Type 096 -- and the newest class of nuclear attack submarine (SSN) -- the Type 095.

The world's largest nuclear submarine factory will provide a leap in China's nuclear submarine construction ability. This plant was completed in 2017, meaning that from 2017 onwards, the Chinese Navy had the potential to accelerate its own nuclear submarine construction program and production speed. The plant, which is specially prepared for the new production of nuclear submarines is about two nuclear submarines in length. From the length it can accommodate two Xia or Shang nuclear submarines. Nuclear submarine construction order is first completed module are built, then sectional construction takes place, with sections finally entering the Assembly hall.

Col Vinayak Bhat (retd) is a Military Intelligence veteran of the Indian Army with vast experience of satellite imagery analysis. He has worked as a Chinese interpreter and is a specialist on PLA and Pakistan’s armed forces. He tweets @rajfortyseven. He noted in October 2017 that when the shipbuilding heavy industry built the Type 094 "Jin" strategic nuclear submarine around 2005, it felt the need for a larger construction site. However, limited to funds, there is no large-scale expansion, only in 2007-2013 in the plant area for reclamation. However, with the advancement of the construction of the oceanic navy and the availability of funds, the nuclear submarine related projects of the Barrier Heavy Industry were further developed. The new facility on the east side of the barge heavy industry began construction in 2015, and by the middle of 2016, new facilities began to emerge.

In the observation of the satellite images, there were some components that may belong to the new submarine. One of them may be that the segment width of the casing is about 16.5 meters. This may mean that the new submarine is more than 16.5 meters wide, and it is probably the 096 strategic nuclear submarine that can carry 24 "Julang"-3 intercontinental ballistic missiles. The width of 16.5 meters plus the turtle's back of 4 meters makes the submarine enough to accommodate almost all of the existing "Dongfeng" series of ballistic missiles in China. This could be a ruse, as making a few parts and laying them out in plain view of satellites isn't standard when building nuclear submarines. Either someone made a big mistake or they deliberately left those parts there to be photographed.

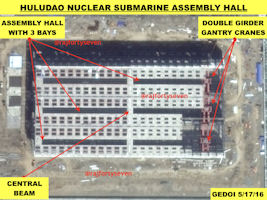

One of the huge assembly workshops has a specification of about 285 meters x 130 meters and covers an area of 40,000 square meters. The overall scale is comparable to the No. 42 workshop of nuclear submarines such as the "Borei" manufactured by the Russian North Machinery Manufacturing Plant. There are 3 passages in the workshop, all with double-beam double-beam gantry cranes up to 9 meters wide, which means it can carry huge objects. On the back of the assembly shop there is another large workshop measuring 200 m x 170 m, which is likely to be used to build submarine sections. A transfer chute is provided between the two workshops, which can be conveniently used to transport the produced segmented modules to the assembly location.

The new facilities accelerated the production of Chinese nuclear submarines by “six times”; the new facilities have also enabled the yard to have the ability to build six nuclear submarines at the same time; The space also allows workers and equipment to operate in severe weather conditions at the same time, and can avoid the observatiosn of the construction of nuclear submarines by other countries' satellites.

By 2019 the exterior structures of the facility appeared substantially complete, although construction of interiors evidently continued. Several sizeable ancillary buildings that were not foreshadowed in earlier imagery had appeared. Of particular note is the building directly adjacent to the south of the main assembly hall, which appears to be slightly greater in size that one of the six main hall assembly bays. One of the abiding puzzles of this complex has been the question of just how they proposed to get the boats into the water. If the logic of the analogous [though much smaller] American facility of General Dynamics Electric Boat had been followed, modules would have entered the main construction hall from the West [the left in the imagery], and been extruded into the water to the East, [the right in the imagery]. Such a capability is not in evidence. It had been previously suggested that the dry docks to the West of this complex might be used, and this appears to be the case. A finished submarine would exit the main assembly hall, and be placed into the smaller parallel building for final finishing. It would then proceed the distance to the dry dock for entering the water.

It cannot be over-emphasized that the main assembly hall, considered as General Dynamics Electric Boat with Chinese characteristics, is really quite huge, roughly three times the floor space of the Land-Level Submarine Construction Facility (LLSCF) has an annual production capacity of 3 nuclear-powered attack submarines (SSNs). The main assembly hall at Huludao can accommodate six boats simultaneously, versus two at Electric Boat. The implicit production capacity of some combination of at least half a dozen boats [some mix of Type 096 SSBN and Type 095 Sui SSN ] is food for thought. A build rate of four attack submarines per year would result in a Chinese fleet that would numerically rival, if nor surpass, that of the United States by the early 2030s.

| Operator | location | facility | dimensions | years |

|---|---|---|---|---|

| Meyer-Verf | Papenburg | shop 6 | 504 x 150 x 70 m | 2008 |

| Sevmash | Severodvinsk | workshop 55 | 436 x 130 x 55 m min | 70s |

| ChSZ | Nikolaev | - | 400 x x m | |

| Meyer-Verf | Pepenburg | shop 6 | 380 x 150 x 70 m | 2001 |

| Meyer-Verf | Papenburg | workshop 5 | 360 x 150 x 60 m | 1990s |

| Volksverft | Stralsund | - | 300 x 108 x 74 m | 1996 |

| Sevmash | Severodvinsk | workshop 50 | 302 x 44 x 40 m | 1939 |

| Bohai | Huludoa | 285 x 130 x 50 m | 2019 ? | |

| Electric Boat | Groton, CT | LLSCF | 150 x 85 x 50 m | 1977 |

| Newport News | Newport News, VA | MOF | 140 x 100 x 30 m | 1986 |

The July 2017 US Navy report to Congress on the submarine industrial base and the viability of producing additional attack submarines explicated the extent to which the floor space of the final assembly hall is not the long pole in the tent for annual shipbuilding rates. the report concluded that building a steady cadence of two Virginia-class Submarines [VCS] per year during the procurement years of the COLUMBIA Class SSBNs was achievable. New facilities at all three yards were in various stages of planning and completion, and remain on track to support the existing programs of record. But existing facility footprint used for VCS would no longer be able to be repµrposed and consumed by COLUMBIA. GDEB's Quonset Point facility would need to accelerate and increase its module construction and outfitting facilities, GDEB's Groton facilities would require approximately an additional 275,000 Sq. Ft. of building space in two facilities, and HII-NNS would require procurement of an additional automated fixture as well as approximately 495,000 Sq. Ft. of associated building and assembly space.

Submarine Building at Bohai Shipyard

The Bohai shipyard was established in 1954 and is located in Huludao, on the northern coast of the Bohai Gulf. The first submarine to be commissioned from this yard in 1987 was the PLAN's first nuclear-powered ballistic missile submarine (SSBN), the Type 092 Xia-class. This boat is a modified version of the PLAN's first-generational design of a nuclear-powered attack submarine (SSN), the Type 091 Han-class. In 1997-98 the Bohai shipyard began construction of a new class of SSN, the Type 093 Shang-class. It has been reported that by late July or early August of 2004 the Bohai shipyard began construction on a replacement for the SSBN Xia-class; the improved SSBN being built is labeled the Jin-class. According to estimates by the US Department of Defense, the SSN Shang-class became operational in 2005-06, and the SSBN Jin-class will become operational 2010 [possibly as soon as 2080] respectively.

This shipyard is in the process of building two new nuclear submarines for PLAN and based on very limited recent production experience, it is projected that the Bohai shipyard is producing approximately one SSN every three years and one SSBN every two years [this seems a bit rapid]. Once various problems get worked out and sea trials prove the operational capability of these submarines, the production levels could be further increased, producing more boats in less time, according to PLAN requirements.

Bohai Shipbuilding Heavy Industry Co., Ltd [BSHIC], the former Bohai Shipyard, is one of biggest assembly shipbuilding enterprises under China Shipbuilding Industry Corporation (CSIC). BSHIC is a modern large coastal comprehensive factory in China for shipbuilding, ship repairing, steel structure processing, metallurgic equipment and large hydropower, nuclear power equipment fabricating and also the official research base for localizing the important technical equipment.

BSHIC has the biggest block fabrication associated workshop of China. The length is 991.8m,the square is 118,000m2. The workshop includes Flat Section Shop, Curved Section Shop and Combined Section Shop. Block fabrications from steel plate cutting, processing to preliminary assembly, sectional assembly are all longitudinally performed in the workshop. The workshop is equipped with stiffener NC plasma cutting lines, block panel production lines and 76 sets advanced equipments, such as NC plasma cutting machines, cranes, oil Presses etc.

BSHIC is situated on the northern coast of Bohai Gulf, north to BEIDAIHE Beach and Shanhaiguan Great Wall (“No.1 Pass Under Heaven”), east to Xingcheng Ancient City. The famous Huludao Port is located in its center. BSHIC covers an area of 3,600,000m2, possesses the total asset of RMB 1.64155 Billion. BSHIC has various kinds of advanced facilities, such as China largest Seven-section covered berths, two 300,000DWT class dry dock, a 150,000DWT class semi-dock building berth, a 50,000DWT class flooding dock etc. BSHIC is capable of building various ships up to 400,000DWT in compliance with the rules and the regulations of all major international classification societies, such as CCS, DNV, BV, ABS, LR, NK, etc. The annual shipbuilding capacity can reach 4,000,000DWT.

BSHIC was certified as National Enterprise Technical Center in 2002. BSHIC has also established a good quality control system which approved by China Xinshida Quality System Certification Body in accordance with ISO9001:2000. In 2003, the Occupational Health & Safety Management System (OHSMS) of BSHIC has approved by China Academy of Safety Science & Technology. Since 2004 BSHIC has been keeping the honor of the National Client Satisfied Enterprise. BSHIC was listed at No. 66 in China Top 500 Machinery Enterprises in 2007 improved from No. 105 in 2005. BSHIC was also awarded as National Credit Enterprise in 2006 and Most Influential Enterprise in 2007. China Enterprise Association and China Entrepreneur Association have both evaluated BSHIC as China Excellent Enterprise in 2008. The Second National Civilized Unit in 2009. The Ten Famous Metal Shipping Industrial of China and also award as China Construction of Manufacture Information Outstanding of The Year in 2010. BSHIC was listed at Top 20 in China the Seventh Top 500 Industry Enterprises in 2011.

Established in 1954, the yard covers 4,500,000 m2. The yard has various kinds of advanced equipment, such as the seven-span type indoor shipbuilding berth [the largest in China], outdoor berths covering more than 20,000 m2 as the extension of the indoor ones, a unique 40,000 ton-class dual-stage water-filled drydock, the largest indoor bridge cranes in China which have the combined lifting capacity of 640 ton by two cranes joint operation, and the 260 m ?50 m semi-dock berth (100,000 tonnage class) with 480 tons of gantry crane capacity where could built various vessel up to 150,000 DWT.

Established in 1954, the yard covers 4,500,000 m2. The yard has various kinds of advanced equipment, such as the seven-span type indoor shipbuilding berth [the largest in China], outdoor berths covering more than 20,000 m2 as the extension of the indoor ones, a unique 40,000 ton-class dual-stage water-filled drydock, the largest indoor bridge cranes in China which have the combined lifting capacity of 640 ton by two cranes joint operation, and the 260 m ?50 m semi-dock berth (100,000 tonnage class) with 480 tons of gantry crane capacity where could built various vessel up to 150,000 DWT.

Bohai Shipyard was conferred the ISO9002 certificate of in 1994. Since 1994 the yard has engaged in the international shipbuilding market and contracted with various owners in the world, such as Germany, USA, Singapore and Canada etc. for building 28,200 DWT log/bulk carriers; 29,000 DWT multi-purpose bulk carriers; 35,000 DWT product oil tankers and so on. Sales volume in terms of the foreign currency is about one hundred million United States Dollars per year.

The yard has been awarded the enterprise honor of AAA class every year since being authorized to export vessels to foreign customers in 1996. The military products developed and fabricated by the yard have been awarded two medals of the National Science and Technology Advanced Special Prize. The yard had developed and built more than 140 vessels by 2000. Among them, the first river-sea shallow draft 10,000DWT coal carrier in China was awarded the National Science and Technology Advanced Prize; the first 35,000 DWT shallow draft economical bulk carrier was awarded the special grade prize of the essential technical facilities awarded by the State Council; the 35,000 DWT product oil tanker was evaluated as the National Class New Product.

The shipyard has expanded into non-marine products, including metallurgy, electric power, railroad and chemical engineering markets. The yard has built a hot blast-furnace and a 250 ton converter for Bao Steel, along with the rotor core for a 300,000 kW hydraulic turbine generator and the platreating reactor of the hot steel wall with production of 800,000 tons per year. The yard has attained the license of design and fabricating pressure vessels of Class I, Class II and Class III.

The Liaoning Shipbuilding Group, formed in late 1997, includes Bohai Shipyard, Dalian Shipyard and Dalian New Shipyard. In April 1997 the State Planning Commission approved the construction of a shipbuilding facility for vessels of 100,000-dwt at the Bohai Shipyard. At a cost almost $24 million, when completed at the end of 1998 it was able to build 2.5 ships annually.

In June 1997 Sembawang Corp. [SembCorp] and Jurong Shipyard Ltd. (JSL) merged, creating one of the world's largest ship repair groups. SembCorp's ship repair and conversion assets include Sembawang Shipyard in Singapore, as well as a 50 percent stake in Bohai Shipyard in Tianjin, China, and a 65 percent stake in PT Karimun Shipyard. In early 1998 Bohai Shipyard announced that it had cut 500 employees, about 10 percent of its personnel.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|