Manufacturing Jobs

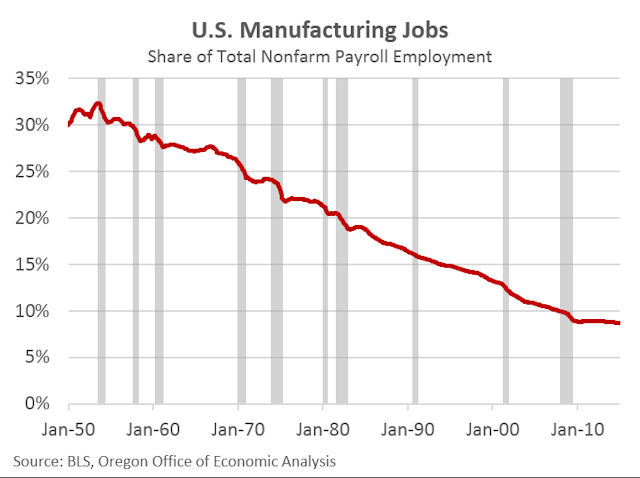

the U.S. economy has entered what some call a post-industrial phase; employment growth is primarily in professions and services rather than primary (extractive) or secondary (manufacturing) sectors. Such employment is much more flexible in its location, and there has been a more rapid growth in such employment in areas that appear to contain greater amenities.

The Manufacturing sector comprises establishments engaged in the mechanical, physical, or chemical transformation of materials, substances, or components into new products. Establishments in the Manufacturing sector are often described as plants, factories, or mills and characteristically use power-driven machines and materials-handling equipment. However, establishments that transform materials or substances into new products by hand or in the worker's home and those engaged in selling to the general public products made on the same premises from which they are sold, such as bakeries, candy stores, and custom tailors, may also be included in this sector. Manufacturing establishments may process materials or may contract with other establishments to process their materials for them. Both types of establishments are included in manufacturing.

The efficiency wage theory is often cited as one explanation for the existence of a manufacturing wage premium. This states that many firms pay higher wages in order to encourage more cooperation from the workforce and minimize turnover (Krueger and Summers). Others have noted that industries with larger firms tend to pay more (Dickens and Katz). This supports the efficiency theory because workers are more difficult to monitor as firm size increases. Paying these workers more discourages shirking without necessitating higher levels of monitoring. Furthermore, studies have shown that the higher productivity levels and the ratio of real value-added to the number of manufacturing employees accounts for the premium.

The manufacturing sector has been steadily “upskilling” in the new century: more manufacturing employees are higher educated and higher skilled than in the past. Since 2007, more than half of all manufacturing workers have completed some college classes, and the proportion continues to increase.

Overall 13 percent of manufacturing workers have n science, technology, engineering and mathematics (STEM). jobs, compared with 5 percent of workers in other private industries. Because a college education is the main path to many STEM positions, it not surprising that the STEM employment share increases with educational attainment.

When most people think about job quality, pay levels are the first metric that comes to mind. By this measure, manufacturing jobs are good jobs: a basic comparison of average wages shows that hourly wages and salaries were 8 percent higher in manufacturing than other private industries as of 2010, based on National Income and Product Accounts (NIPA) data available from the Commerce Department’s Bureau of Economic Analysis.

Manufacturing workers are more likely to have the option of medical care and retirement benefits. Ninety percent of manufacturing employees have access to medical care benefits, compared with 66 percent of workers in private service-providing industries.6,7 And 78 percent of manufacturing workers receive employer contributions to their retirement benefits (primarily to defined-contribution plans), versus 62 percent of workers in service providing industries.

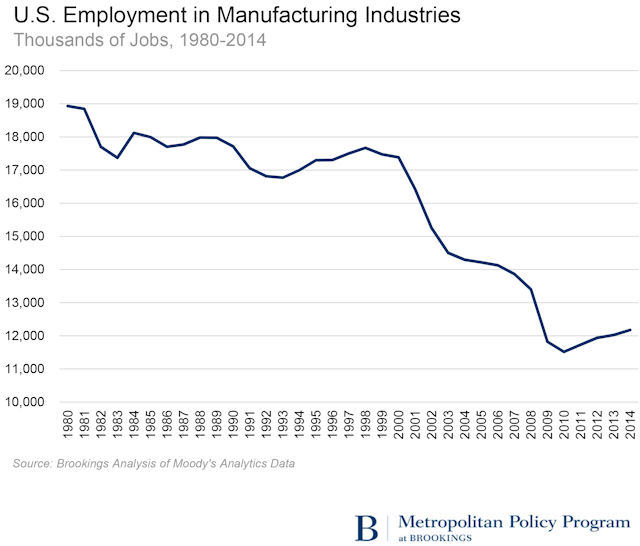

Some US manufacturing jobs have gone to nations with lower wage costs. The precipitous decline in US manufacturing jobs after the year 2000, when China entered the World Trade Organization, seems to be an example of this effect. The US has lost 5 million manufacturing jobs since 2000.

In an effort to reverse that trend, Trump said he would try to get Congress to impose a 35 percent tax on products made in other countries by companies that have left the US and then try to send them back across the border. That, however, could ignite an international trade war.

Far more jobs have vanished because growing efficiency from automation and robots means fewer people are needed in the manufacturing process. Workforce experts blame the loss of millions of US manufacturing jobs on the rising capability of computer automation. One example: the U.S. auto industry built and sold a record number of vehicles in 2015, but did so with many fewer workers than it once employed.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|