NEWCON Cadet Training Ships (CTS)

The First Training Squadron under the Southern Naval Command comprises ships ‘Shardul’ (originally an amphibious ship), the aged ‘INS Tir’ which recently underwent an extensive refit, ‘INS Sujata’ (built as a patrol vessel), Coast Guard ship ‘Sarathi’, and sail training ships ‘Tarangini’ and ‘Sudarshini’. It takes care of sea training of cadets.

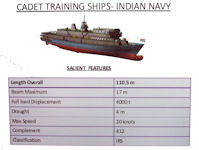

With the expansion in infrastructure in mind, the Navy, following proper tendering procedure, contracted the private sector ABG shipyard for building two purpose-built vessels for ‘afloat’ training of cadets. The 970-crore rupees contract was awarded in June, 2011, but what was hailed as a big push to the private sector in naval ship building soon ran into problems, thanks to design issues. Each of the two vessels was to be 110 metres long, with a displacement of 4,000 tonnes, and capable of cruising at 20 knots. According to the contract, the first vessel was to be delivered in 42 months and the next, six months later. But construction delays marred the project and the Navy was forced to convert operational vessels for training requirements of the squadron in the meantime.

Cutting of steel for the first of the two naval cadet training ships contracted to be built by the ABG Shipyard in Gujarat was anticipted at the shipyard in the first week of February 2012. The ships are meant to replace the ageing INS Tir, the lead ship of the Southern Naval Command-based First Training Squadron, and the soon-to-be decommissioned INS Krishna. Built to the Indian Register of Shipping (IRS) classification, the proposed cadet training ships will displace 4,000 tonnes each — far higher than the existing vessels — and will feature high-efficiency controllable pitch propellers (CPP) powered by two diesel engines through a twin shaft.

The Navy's First Training Squadron was at a critical juncture in history with INS Tir having completed over 25 years in service and INS Krishna about to be paid off. Interim measures — such as allocation of landing ship INS Shardul for training for six months and conversion of patrol vessel INS Sujata into a training ship — had been put in place by the force to ensure that training of cadets did not suffer during this phase of transformation lasting nearly four years by which time the proposed cadet training ships would be available for operation by the squadron.

In 2015, Vice Admiral Sunil Lanba, head of the Southern Naval Command — later Admiral and chief of the Navy — told The Hindu that the project had resumed after money had been pumped into the cash-strapped yard as part of a corporate debt restructuring (CDR) measure. He said the first ship would be ready by the end of 2016. Reports, however, suggest that the debt-laden shipyard had filed for bankruptcy, following which the procedure was under way on the part of the banks that had lent it funds to put it on the block.

The Indian Navy was tracking the insolvency proceedings of ABG Shipyard after the Navy was forced in 2017 to terminate shipbuilding contracts worth Rs 1,455 crore five years after it was first awarded to the firm. The failure of ABG Shipyard, which owes close to Rs 19,000 crore to its creditors, to deliver three training vessels has the Navy questioning public-private partnerships in building warships and officials believe the termination of the contract has set the Navy’s schedule back by at least a decade.

-

The Navy now needed to actually start the entire process, foreclose that contract and then go into fresh tendering, get fresh sanctions. That will put the Navy behind at least by a decade. On 20 April 2018 the Ministry of Defence, Government of India, announced intent to procure three Cadet Training Ship (CTS) from Indian shipyards. Cadet Training Ship (CTS) in its primary role should be capable of providing basic sea training to naval cadets and also carry out the role of hospital ship, HADR (Humanitarian Assistance and Disaster Relief), Non-Combatant Evacuation Ops (NEO) and Search and Rescue (SAR) in its secondary role. Details were specified in the operational/technical requirements.

Quantity Required and Anticipated Delivery Timeframes are three CTS are proposed to be acquired. The anticipated delivery timelines for the first vessel is 36 months followed by delivery of one vessel every 6 months.

Solicitation of offers will be as per ‘Single Stage-Two Bid System’. It would imply that a ‘Request for Proposal’ would be issued soliciting the technical and commercial offers together, but in two separate sealed envelopes. The validity of commercial offers should be at least 18 months from the last date of submitting of offers. The technical offers would be evaluated by a Technical Evaluation Committee (TEC) to check its compliance with RFP. Among the shipyards cleared by TEC, a Contract Negotiations Committee (CNC) would decide the lowest cost bidder (L1) and conclude the appropriate contract. The shipyards would be bound to provide product support for time period specified in the RFP, which includes spares and maintenance tools/ jigs/ fixtures/ documentation for training for field and component level repairs.

The ship should be able to sustain at sea for at least 60 days. The ship should have two Diesel Engines and Twin Shaft with Controllable Pitch Propeller (CPP), with a single Diesel Engine on each shaft and Bow Thruster. The Main Engines should be capable of being exploited at least up to 4500 hours per engine, during one Operational Cycle.

Latest ship design concepts, with respect to ergonomics/ functional aspects and crew comfort are to be adopted. Layout of bed/ bunks is to cater for minimising discomfort due to ship roll/ pitch. Equipment should be sited, so as to cause the least disturbance to crew, in operational compartments and in living spaces. Noisy equipment such as motors, pumps and converters should not be fitted inside compartments such as Bridge and Weapons Control Room.

Design should allow easy accessibility to machinery/ equipment. Shipping IN and OUT routes for all equipment including galley equipment and stores, should be catered. Doors, hatches and ladders are to be of modern design, to ensure easy and safe closing/ opening and speedy movement of personnel and equipment/ stores within the ship.

COTS technology is to be incorporated, to the maximum extent feasible. Automation in hotel/ domestic services, ship husbandry, maintenance, logistics and management services is to be maximised. Modular concept should be followed as far as possible. Automation of power management is to be provided.

Modular and ergonomically designed furniture should be fitted onboard the ship. Manned spaces, excluding the Hangar, or where specified otherwise, are to be air conditioned to maintain an effective temperature of not more than 24°C. Unless specified otherwise, the humidity values and temperature for specialised locations like Workshops, Safety Equipment Room, POL Stores, etc, should be 45 to 55 percent relative humidity at 21°C.

Green Warship Design features and technologies that are energy efficient and environment friendly should be incorporated.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|