Maritime Support Vessel (MSV)

MV Ocean Trader M/V Cragside

A French news agency reported the arrival of the renamed MV Ocean Trader in the Mediterranean on May 16, 2016. According to Maritime Administration records, the ship was renamed on October 30, 2015 and remains on the rolls as a U.S. flagged merchant ship as of July 1, 2017, although a few of the sources identify the ship as Marshall Island flagged. Checks of various Automatic Identification Systems (AIS) has the ship in Gibraltar on May 14, 2017, Souda Bay, Crete on May 24, 2016, and Amsterdam on August 16, 2017. The ship does not currently show up on any active AIS systems.

A French news agency reported the arrival of the renamed MV Ocean Trader in the Mediterranean on May 16, 2016. According to Maritime Administration records, the ship was renamed on October 30, 2015 and remains on the rolls as a U.S. flagged merchant ship as of July 1, 2017, although a few of the sources identify the ship as Marshall Island flagged. Checks of various Automatic Identification Systems (AIS) has the ship in Gibraltar on May 14, 2017, Souda Bay, Crete on May 24, 2016, and Amsterdam on August 16, 2017. The ship does not currently show up on any active AIS systems.

Maersk Line Ltd., Norfolk, VA, was awarded a $73,677,038 firm-fixed-price contract on 12 November 2013 for the time charter of one US-flagged, twin-shaft vessel, which would function as a maritime support vessel. This contract includes four 12-month option periods, which, if exercised, would bring the cumulative value of this contract to $143,149,058. Work will be performed at sea worldwide, and is expected to be completed November 2014. If all options were exercised, work would continue through October 2018. Working capital contract funds in the amount of $73,677,038 was obligated for fiscal 2014, and would not expire at the end of the current fiscal year. This contract was competitively procured with over 200 proposals solicited via a solicitation posted to the Military Sealift Command and Federal Business Opportunities websites, with 13 offers received. The Military Sealift Command, Washington, DC, is the contracting activity (N00033-14-C-2015).

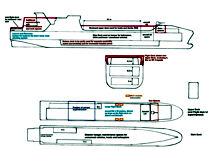

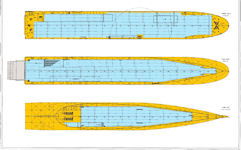

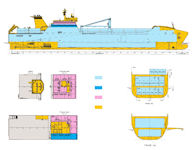

Built in 2011, the MV Cragside is owned by Maersk, and the US Sealift Command is buying her services on an annual basis. The MV Cragside is from the same design family as those operated in the UK’s Point Clas Strategic RORO Service. The RoRo 2700 Strategic Sealift Flensburger RoRo design has been specially modified for strategic sealift operations. Because it is based on a very successful RoRo design it has been possible to retain maximum load and performance whilst introducing new features to meet the high military requirements. By adhering to merchant Navy standards wherever possible, building and operational costs can be kept to a minimum. As the seakeeping behaviour of a this vessel is of utmost importance for both safety of the crew and reliable transport of cargo, our design includes a passive stabilizing system of the Flume Tank type, which is the balance considering efficiency, cost and complexity. Special attention was paid to excellent speed-power performance with significantly low fuel oil consumption as well as excellent sea keeping behaviour and good manoeuvrability.

Requirements

Military Sealift Command (MSC) requested a US flagged vessel which would function as a Maritime Support Vessel (MSV). The vessel shall serve host to fifty (50) Sponsor personnel with the ability to surge an additional one hundred fifty-nine (159) personnel, for a total of two hundred nine (209) Sponsor personnel, within twenty-four (24) hours notice. The vessel shall maintain sufficient stores onboard to support the crew and fifty (50) Sponsor personnel for a minimum of forty-five (45) days without resupply.Additionally, the vessel shall have sufficient storage capacity to support at sea operations for all two hundred nine (209) personnel for a minimum of forty-five (45) days without resupply. The vessel shall be Underway Replenishment (UNREP) (Fueling at Sea (FAS) and Vertical Replenishment (VERTREP)) capable to include fuel and supplies with the standard Coalition/USNS logistics ships in order to extend operations for a maximum of ninety (90) days. The vessel shall support launch, recovery, refueling, and resupply of small craft, provide organic force protection and perform stowing, transport, launch/recovery, re-fueling of manned and unmanned rotary wing aircraft. The vessel shall provide equipment stowage, messing, berthing, administrative/operational space, maintenance space, emergency towing, and logistics services in support of operations. The contractor shall independently operate all deck equipment to include the craft handling/launching systems.

The vessel shall be able to maintain course and speed in storm conditions of 50 knot winds and/or seas of up to 20 foot significant wave height. Vessel shall support small craft launch and recovery operations. Alongside refueling operations with small craft shall be conducted in maximum sea conditions. The vessel shall be required to loiter for long periods of time as a re-supply station for small craft. The vessel shall have the capability to maintain directional stabi lity below two knots.

The vessel shall maintain sufficient stores onboard to support the crew and fifty (50) Sponsor personnel for a minimum of forty-five (45) days without resupply. Additionally, the vessel shall have sufficient storage capacity able to support at sea operations for all two hundred nine (209) personnel for a minimum of forty-five (45) days without re-supply. The vessel shall be Underway Replenishment (UNREP) (Fueling at Sea and Vertical Replenishment) capable to include fuel and supplies with the standard Coalition/USNS logistics ships in order to extend operations for a maximum of ninety (90) days. The vessel shall be capable of burning diesel fuel in order to receive fuel during FAS.

The helicopter facilities shall meet the requirements of Aviation Attachment 4 to achieve a NAVAIR Level I, Class 2 certified facility (day and night IMC (Instrument Meteorological Conditions) landing facilities with service but no maintenance facilities) for the following aircraft: MH6, AH6, MH47G, MH60K, MH60L, MH60M, UH60L, CH47 D-F, OH58D, AH64 A-D, MV/CV 22, HH60H, HH60J-T, SH60 B-F, MH60R, MH60S, and the MH53E. A recovery assist, securing, and traversing system (RAST) is not required. The flight deck, aircraft parking areas, and hangar deck shall withstand the landing loads and parking loads associated with moderate and storm sea conditions (sea state 5) for all aircraft.

The contractor shall provide helicopter facilities with the ability to simultaneously launch/recover two (2) MH-60 class or one (1) CH-53E class helicopter with clear, unobstructed vertical airspace. Helicopter facilities shall comply with the requirements of USCG Navigation and Vessel Inspection Circular No. 9-81 for day and night landings with instrument meteorological conditions (IMC) for the following aircraft: MH6, AH6, MH47G, MH60K, MH60L, MH60M, UH60L, CH47 D-F, OH58D, AH64 A-D, MV/CV 22, HH60H, HH60J-T, SH60 B-F, MH60R, MH60S, and the MH53E.

The flight deck shall also meet NAVAIR requirements for Level I, Class 4, Special Type 2 vertical replenishment operations (VERTREP) for the H-60 series, CH-53K, H-46, CH-47, and V-22 aircraft. The contractor shall provide adequate tie-down locations for an Unmanned Aerial Vehicle (UAV) and all rotary wing aircraft shall be restrained in sea state 5. The flight deck must be reachable by material handling equipment in order to move equipment (5,000 lb pallet) to below deck storage areas. The contractor shall provide all necessary yellow gear to move equipment and aircraft around the flight deck.

The Government may take delivery of the vessel prior to the flight deck receiving certification if the delay in certification is caused by the Government and if the contractor is able to demonstrate that the vessel, as delivered, is constructed to meet Aviation Attachment 4 requirements, NAVAIR 4.8.2.5 Air Capable Ship Aviation Facilities Bulletin No. 1M requirements, and USCG Navigation and Vessel Inspection Circular (NVIC) flight deck requirements.

The contractor shall provide four (4) launch and recovery systems to launch and recover up to 12.5m x 3m craft with a minimum draft of 2m. The launch and recovery system shall be capable of lifting and supporting 30,000 pounds per craft and shall meet the requirements of the ABS Guide for Certification of Lifting Appliances (latest revision), including the requirements for personnel lifting. The contractor shall be able to launch two (2) manned craft in 20 minutes. The maximum speed for the vessel when conducting launch and recovery is 10 knots, depending on the launch and recovery mechanism used; the minimum speed for the vessel when conducting launch and recovery is 1-2 knots.

The contractor shall provide a covered storage area with a minimum of:

- 18 ft height, with minimum 30 ft opening to accommodate eight (8) craft up to 12.5m x 3m, one (1) 10m craft, four (4) Jet Ski craft and four (4) Zodiac F470.

- Must be adjacent to the craft launch and recovery systems to allow for easy transfer and movement of personnel and equipment and ease of maintenance.

- Must be sealed from the outside environment to prevent saltwater or outside air intrusion into the space.

- No portion of the interior may be visible to any outside observer.

- 500 sq ft mechanic workspace with workbench, modular drawer storage cabinets (Vidmar or equal), electrical outlets, and compressed air.

- 300 sq ft secure communications storage and coxswain electronics maintenance space.

- Exhaust fans to allow removal of craft engine exhaust and to facilitate the drying of craft and equipment.

- 5 ft of clearance shall be provided around the front and back of each of the eight (8) craft.

The contractor shall provide berthing/habitability accommodations for two hundred seven (207) Sponsor personnel. Adequate showers/heads shall be provided. All accommodations shall be air conditioned and heated. The contractor shall ensure all heating, ventilation, and air conditioning (HVAC) systems for all Government living spaces shall be designed in accordance with Society of Naval Architects and Marine Engineers (SNAME) Technical and Research Bulletin 4-16, except that the design shall be based on 105 degrees F ambient air and 95 degrees F sea water temperature. These design parameters should also be factored into the design of any systems using seawater or ambient air as a heat transfer medium. In addition, each room shall require two (2) LAN drops. The contractor shall make available self-service laundry facilities. The contractor shall provide commercial grade heavy duty machines to accommodate two hundred seven (207) Sponsor personnel. Laundry facilities will be available at all times and will include a sufficient amount of cleaning supplies, iron, ironing board and ironing board cover.

The contractor shall provide galley-prepared food service. Food provided shall have the most reasonably attainable degree of variety, quality, quantity, and nutritional value available in the maritime industry. Special menu requests for vegetarians and people with food allergies, medical restrictions, and religious restrictions shall be made thirty (30) days in advance by the Sponsor. Meals will be served daily as follows: Breakfast, 0730-0830; Lunch, 1130-1230; and Dinner, 1700-1800. Mealtimes shall be varied or extended to accommodate operational considerations. Quantities of food for the above meals shall be unrestricted. Cafeteria service shall include tablecloths, ceramic dishware, glasses and metal utensils. The OICs concurrence should be obtained in advance for all meal plans. The OIC shall notify the contractor of the number of personnel remaining aboard the ship during inport periods. Meal items at a minimum shall consist of:

- BREAKFAST: Eggs/omelets (any style); breakfast meat (one); pancakes, waffles or French toast; fruit (fresh when available); donuts, bagels or sweet rolls; bread and toast; butter, jelly and syrups; hot cereal; cold cereals; potatoes (any style); fruit juice; coffee, tea, milk, cocoa, and water.

- LUNCH: One sandwich-type item (e.g., hamburger, tuna salad, grilled cheese, etc.); two (2) additional entrees (one (1) of which shall be hot and one(1) of which shall consists of meat); choice of two (2) vegetables; rice/potatoes; soup; salad bar (containing variety of vegetables and condiments); diet plate; fruit; bread and butter; two (2) desserts plus ice cream; coffee, tea, milk, and water.

- DINNER: Three (3) entrees (two (2) of which shall be hot and two (2) of which shall consist of meat); choice of two (2) vegetables; rice/potatoes; soup; salad bar (containing variety of vegetables and condiments); diet plate; fruit; bread and butter; two (2) desserts plus ice cream; coffee, tea, milk, and water

When requested by the OIC, the contractor shall provide Sponsor personnel assigned to the night watch with hot lunches served between the hours of 2330-0030. This “hot lunch” is not intended to be treated as a fourth meal. It is designed for Sponsor personnel who have missed the third meal. Sponsor personnel assigned night watch will be allowed to select items from the lunch or dinner menu to be set aside in microwaveable containers marked with their name, or the OIC may, at his option, request a hot lunch be prepared. Overtime is reimbursable for the crewmember(s) preparing the hot meal at the OICs request. Prepared hot lunches shall consist of one (1) breakfast entree; one (1) dinner entree; coffee, tea, cocoa, and milk; bread and butter. Either the breakfast entree or dinner entree shall contain meat. All overtime associated with this night meal service will be coded Sponsor-Support overtime (OT).

The contractor shall provide snack foods for Sponsor personnel twentyfour (24) hours per day. Snack foods shall include foods like Deli-meats and breads; relishes; cheese and crackers; fresh fruit (when available); peanut butter; jellies/preserves; cookies; popcorn; ice cream bars/yogurt; potato chips; coffee, tea and milk; hot cocoa mix.

Leftovers shall not be frozen and shall not be retained if not used within twenty-four (24) hours. Foods composed of ingredients having been peeled, chopped, sliced, or diced by hand after cooking shall NEVER be saved as leftovers. Cream puffs, custard-filled pies, cakes, éclairs, and similar products, including those containing synthetic fillings, shall be prepared under strict sanitary conditions, covered, cooked quickly, and refrigerated until served. Leftovers shall remain under refrigeration on the serving line, and any leftover items shall be disposed of at the end of the day.

| VESSEL | REQUIREMENTS | M/V Cragside |

| Maximum Length (overall) | 700 ft | 627 feet 193.00 meters |

| Length (between perpendiculars) | 182.39 meters | |

| Breadth | 26.00 m | |

| Depth to main deck | 8.60 meters | |

| Depth to upper deck | 16.70 meters | |

| Draft (summer load) | 7.40 meters | |

| Draft (design) | 5.70 meters | |

| Maximum Draft | 30 ft | |

| Design deadweight | abt.6,650 tons | |

| Summer load | abt.13,300 tons | |

| Gross tonnage | abt. 23,320 GT | |

| Net tonnage | abt. 16,996 NT | |

| Propulsion |

| |

| Fuel | 380 cSt at 50° C or MD | |

| Minimum Vessel Speed | 20 knots sustained for five (5) days (120 hours) | |

| Service speed | 21.6 knots (at design draft of 5.70 m, 90% MCR (14,580 kW ), 10% sea margin and shaft generators engaged ( abt. 800 kW )) | |

| Max. cruising range | abt. 10,000 sea miles | |

| Minimum Range | 8,000 nautical miles (NM) | |

| Fuel Consumption | 61.2 t/d |

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|