KRND Burevestnik - Technology

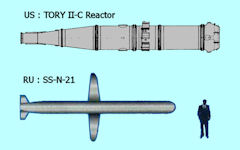

Russian sources are otherwise silent on this program, and provide no details as to the nuclear propulsion system. The claim that the reactor could fit within the American Tomahawk cruise missile, with a diameter of about 0.63 meters [21 inches] is particularly hard to swallow.

Russian sources are otherwise silent on this program, and provide no details as to the nuclear propulsion system. The claim that the reactor could fit within the American Tomahawk cruise missile, with a diameter of about 0.63 meters [21 inches] is particularly hard to swallow.

Western analysts have made no public effort to clarity the technical details of this project. Stephen Schwartz, the noted analyst and author of the book The Costs And Consequences Of U.S. Nuclear Weapons, said the design of the nuclear-powered cruise missile echoed a U.S. weapon tested in the 1950s and 1960s, with a nuclear “ramjet” engine. “It was an especially nasty concept. The reactor was unshielded, emitting dangerous levels of gamma and neutron radiation. And as it flew, it would spew radioactive fission fragments in its exhaust, including over allies en route to the U.S.S.R.,” he said.

According to statements by Russian President Vladimir Putin and materials from the Russian Ministry of Defense, it is believed that in terms of body dimensions the missile is comparable to the X-101 cruise missile and is equipped with a small-sized nuclear power plant. The declared flight range is tens of times greater than the flight range of the X-101. In footage of official presentations, the rocket is launched from an inclined launcher using boosters.

Putin revealed new details about the Burevestnik nuclear-powered cruise missile on 29 October 2025, saying its nuclear reactor is "1,000 times smaller than that on a submarine" and can be started in minutes, while a submarine reactor takes hours. Putin called it a major breakthrough and a "huge achievement" in the field of engineering. Russian Chief of the General Staff Valery Gerasimov reported on October 21 that the Burevestnik V flew 14,000 kilometers over 15 hours during the test, successfully completing multiple maneuvers and demonstrating a high degree of ability to evade missiles and air defense systems.

According to Military-Industrial Courier expert Pavel Ivanov: “...in terms of dimensions, the newest missile is one and a half to two times larger than the “one hundred and first”. Unlike the latter, the wings of the Burevestnik are located not at the bottom, but at the top of the fuselage. You can also see the characteristic protrusions in the video. Most likely, this is where the air is heated by a nuclear reactor... The mass of the Burevestnik is several times, and probably an order of magnitude, greater than that of the X-101 . ”

According to Nezavisimaya Gazeta, the rocket's starting engine is solid fuel, and its propulsion engine is a nuclear air-breathing jet. Dimensions: length at launch - 12 m, in flight - 9 m, the body in frontal projection has the shape of an ellipse 1x1.5 m.

On March 3, 2018, the TASS agency, citing a military-diplomatic source, reported the completion of tests of a small-sized nuclear power plant that can be used in the production of cruise missiles and underwater vehicles. Jeff Terry, a physics professor at the Illinois Institute of Technology, using Tomahawk cruise missile analogies, estimated the net (non-thermal) power of the Petrel's engine to be approximately 766 kW. From this he concludes that this is well within the potential power range of a modern generation compact nuclear reactor.

The range and endurance of present day aircraft [and cruise missiles] are limited by the amount of expendable fuel they carry. The utilization of fossil fuels necessitates a large number of mechanical and electrical devices which decrease the overall reliability of an aircraft. These include fuel cells, fuel pumps, fuel transfer pumps, level sensors, fuel level indicators, valves and piping. Further, aircraft aerodynamics are adversely affected on account of storage requirements for fuel. Aircraft performance may vary as fuel is consumed due to a shift in an aircraft's center of gravity during flight.

Nuclear power has long been considered an alternative to fossil fuel. Further, prior approaches have involved large reactors which present problems in terms of practicability. Efforts have been made in the past to design turbojet engines which utilize nuclear fission reactors in the place of the combustion chamber as a source of heat. Unfortunately, these efforts have resulted in designs in which the engines were excessively heavy or occupied excessive volumes, especially when it came to meeting shielding requirements, and in which the control systems did not have the degree of reliability which one would like to have in aircraft engines. A variety of other problems, as well, have not heretofore been adequately dealt with in prior designs, so that efforts have been continuing to obtain a safe, reliable economic and practical system combining the turbojet and the nuclear power source.

This missile would use a so called "direct open cycle-gas cooled propulsion reactors". The words "direct open cycle" signify that the working fluid is heated by direct contact with the surface of the reactor fuel elements, and is exhausted to the atmosphere or to space as the propellant rather than recirculated in a closed loop. The use of the words "gas-cooled reactor" is a holdover from the early days of reactor development when the concern was to get rid of reactor heat rather than to utilize it.

Active development of direct cycle gas cooled nuclear propulsion reactors in the United States started in 1951 following feasibility studies performed primarily by the NEPA Project of the Faischild Engine and Airplane Company. The reactor development work was performed for three major propulsion systems, the nuclear turbojet, ramjet, and rocket.

Determining the radiation effects on people and equipment was another major question. Two different approaches to the nuclear-powered engine design were pursued, GE’s open cycle, air-cooled reactor, and Pratt and Whitney’s closed cycle, liquid metal-cooled concept. The closed cycle ducted fans using chemical fuels were found to be too heavy and complicated to be competitive with open cycle engines. But the open-cycle engines had the drawback of producing an exhaust plume that might contain radioactive debris eroded from the reactor core, and other contaminants. Active development of the direct air cycle nuclear turbojet started in 1951 under simultaneous contracts between the General Electric Company and United States Air Force and United States Atomic Energy Commission.

The basic nuclear turbojet consists of a nuclear reactor is located between the compressor and turbine. Air is admitted at the forward end, compressed by a turbine driven compressor, heated in the reactor, expanded through the turbine and exhausted from the jet nozzle, thus providing forward thrust. Thrust augmentation for takeoff may be obtained by burning chemical fuel in an afterburner. A chemical interburner may also be utilized ahead of the turbine and in series with the reactor if it is considered desirable to restrict airport operation to chemical fuel utilization. The applications for which the nuclear turbojet is most useful are those involving extended flight at sea level and intermediate altitudes. The American nuclear turbojet program was terminated in 1961.

The nuclear ramjet operates on a thermodynamic cycle which is basically the same as that of the turbojet. Air is admitted at the forward end, compressed by diffusion, heated in the reactor and expanded through the jet nozzle to provide forward thrust. Since sufficient compression is provided by inlet diffusion at high flight speeds, the requirement for rotating turbomachinery is eliminated. The nuclear ramjet is most useful for applications requiring long endurance at high supersonic flight speeds in the atmosphere. Active development of the nuclear ramjet in the United States started in the mid 1950's.

Nuclear thermal propulsion presents a specific impulse which is greater than that which can be produced by chemical propulsion. The heat generated by a nuclear reactor is transferred directly to an expelled gas which is supplied by tanks. In general, the gas is hydrogen because it has the lowest molecular mass. Nuclear thermal propulsion was actively developed in the United States during the 1960s in the context of the NERVA program, and more recently in the context of the Timberwind program. A test installation was implemented on the ground and, over a period of 1 hour, it delivered thrust of 30 tonnes with an impulse Isp of 800 seconds. In-depth studies were also performed in Russia and tests were made on subsystems.

Nuclear thermal propulsion was actively developed in the United States during the 1960s in the context of the NERVA program, and more recently in the context of the Timberwind program. A test installation was implemented on the ground and, over a period of 1 hour, it delivered thrust of 30 tonnes with an impulse Isp of 800 seconds. In-depth studies were also performed in Russia and tests were made on subsystems.

Programs relating to nuclear thermal propulsion are presently going slowly. One possible explanation is that in order to perform better than chemical rockets in terms of impulse Isp, it is necessary to take high risks both in programming terms and in safety terms. Specifically: achieving impulse Isp significantly greater than that generated by present-day stages that burn liquid oxygen and liquid hydrogen implies that nuclear thermal propulsion must have the highest possible temperatures and very high pressures at the interface between the nuclear core and the outlet gases; the required performance would push technology to its limits in a portion of the engine that is critical from the safety point of view; and it is difficult to make the internal temperature of the nuclear core uniform; as a result there is a risk of the engine being degraded because temperature margins are small compared with the technological limits of the materials.

One Russian analysis noted that if supersonic speed isn't required, then a subsonic gas turbine engine can be used instead of a power-hungry ramjet—one with a low-temperature atmospheric air intake by the rocket, heated by the reactor, and expelled. For subsonic flight, the air in the turbine only needs to be heated to 850 degrees Celsius. This temperature is feasible for metal heat exchangers. As such, there's no longer any need to circulate air through the reactor core. It remains sealed and can be cooled with molten metal.

A cruise missile must be as compact as possible. Cooling it with water or gases while maintaining compactness is impossible: heat removal per unit volume will be limited, so the reactor core will have to be larger, and heat transfer to the secondary circuit will be slower. Liquid metals allow a core the size of a large, oblong watermelon. In fact, the USSR began launching similar nuclear reactors—fast neutron reactors cooled by a liquid sodium-potassium mixture—into space as early as the 1960s.

However, it's doubtful that the Burevestnik reactor contains sodium-potassium in its primary circuit (such mixtures typically contain 22 percent sodium, the rest potassium). There are two reasons for this. First, sodium-potassium burns extremely quickly and vigorously when exposed to air. Any leakage leads to a violent fire or explosion (recall the large explosion at Y-12 in the US in 1999).

Secondly, the 2019 incident in Nenoksa may have involved testing a radioisotope energy generator (RTG). According to official data from Roshydromet, traces of strontium-91, barium, and cesium isotopes were detected in the air following this incident. These isotopes are formed by the decay of noble gases released during certain reactor operating modes, as the radioactive contamination from them (under these release conditions) is low and poses no threat to human health. It's known that five VNIIEF scientists died in the incident as a result of a chemical (non-nuclear) explosion. They don't work on reactors, but they do work on RTGs (and nuclear weapons).

But Michael Kofman, a Senior Research Scientist at CNA and a Fellow at the Wilson Center, wrote "there simply was not enough information to tell what happened, and the hot take factory had already run away with the story on the basis of close to nothing. Here is the most likely scenario as I see it. The explosion was not a missile launch test, and it was not Burevestnik, no matter how much arms control wonks want to think it was. It’s just unlikely based on the scant information available about the incident. I have a different view from Jeffrey Lewis here. The notion that Russian Burevestnik program was in major trouble after moving from Novaya Zemlya test site is also probably incorrect.... the linkage to Burevestnik exists entirely in the minds of people who want it to be that weapons program versus 10+ other things it could have been. That’s good enough for CNN but not good enough for analysis.... numerous journalists and experts, with diverse sources of information in Russia, have also all indicated that RTG is the most likely explanation followed by novel nuclear reactor for some application other than Burevestnik...,"

On July 1, 2019, just over a month before the Nenoksa incident, a fire broke out on the AS-31 Losharik, a highly secretive Russian nuclear-powered deep-diving submarine. Fourteen Russian submariners were killed from smoke inhalation The fire started in the battery compartment while the submarine was conducting a survey of the seafloor in Russian territorial waters. The fire on the Losharik occurred at sea, not at the Nenoksa test site. The crew was able to contain the fire and save the nuclear reactor from damage. The Losharik incident also had elements of Russian secrecy and nuclear components, contributing to the broader confusion and conspiracy theories that developed in the public and media.

Though a Radioisotope Thermoelectric Generator (RTG) was initially floated as a possibility by some, the isotope evidence indicated a more active nuclear fission reaction. An RTG uses passive radioactive decay to produce power, whereas the Burevestnik is powered by a nuclear reactor.

Nonetheless, a Russian analyst came bck to the questionof why does the Burevestnik reactor need an RTG? And this is “secondly”: the RTG makes sense there mainly if it is used to maintain a cruise missile in a state of constant readiness for launch. The sodium-potassium has a good analogue: pure metallic sodium. Its positive properties are that sodium is much less hazardous when exposed to air. Yes, it also burns when exposed to air, but only moderately, and, equally important, it won't explode (while sodium-potassium can, under certain conditions—see the US).

Sodium has only one drawback: to keep it liquid, it needs to be heated to almost 100 degrees Celsius. Sodium-potassium becomes liquid at temperatures below zero Celsius, so it can be easily heated with an electric heating element. But heating sodium to 100 degrees Celsius in the same way would be difficult: it requires a lot of electricity. Where can you get it in remote locations where nuclear weapons are often deployed? What happens if the diesel generator there breaks down—how to handle a sudden start-up command?

So, based on the available data, it appeared to one Russian analyst that the nuclear reactor aboard Burevestnik may be sodium-based. Other coolants are unsuitable because their heat transfer is much poorer than that of sodium or sodium-potassium. The conclusion that follows from this is that if the Burevestnik flight tests are indeed close, then there will be no “mini-Chernobyl” there. The sodium-cooled fast-neutron reactors (and they all use fast neutrons) have strong negative feedback. This means that if you somehow manage to overheat the core of such a reactor, the fuel density will begin to drop, causing the nuclear reaction to self-stop.

Emergency shutdowns in such systems are possible, but reactor vessel failure is highly unlikely. There will also be no air activation during normal operation of the flying reactor: the neutron flux outside the reactor core is much lower than inside it. This means, unlike Pluton, the activation of carbon and other elements in the air on Burevestnik will be minimal.

Contrary to a chemically-fueled turbojet Brayton cycle where increased power requires increased fuel flow, and where cycle performance is measureed by applied fuel-specific impulse (pounds of thrust per pound of fuel per second) and where increased power does not necessarily improve the fuel-specific impulse, any increase in power from the energy-abundant reactor can be applied (more or less efficiently) to improve the cycle performance (air-specific impulse) of a nuclear-fueled cycle for which the fuel-specific impulse is nearly infinite.

As all heat transfer propulsion reactors have considerable internal surface area and small size passageways that offer large impedance to flow, thus reducing the cycle pressure level and resulting in less than desirable pressure ratio across the exit nozzle, it becomes important to operate at high reactor pressure.

A Particle Bed Reactor (PBR) is a high temperature gas cooled nuclear reactor. The PBR is a compact, very efficient, high capacity heater for gases which are heated directly by fissioning particulated nuclear fuel. The nuclear fuel particles are contained in fuel elements each consisting of a porous outer pipe and a smaller diameter inner porous pipe with the particulate fuel packed in the annulus formed between the porous pipes. The gas flows radially through the outer porous pipe, over the fuel particles, then through the inner pipe into its axial channel and out of the channel to do work. The fuel elements are arranged in generally concentric circles around a central fuel element in a moderator matrix to form the reactor core. The reactor core is contained in an appropriately configured pressure vessel to form the reactor. Reactor safety is assured by insertion of safety rods when the reactor is not operating. To operate the reactor, the safety rods are withdrawn and reactor reactivity is controlled by varying the depth of the control rods within the reactor.

Particle Bed Reactors (PBR's) first conceived in the early sixties were intended to be an improvement over the solid core reactors developed in conjunction with rocket propulsion programs. The PBR's then proposed consisted generally of an annular bed of nuclear fuel particles held on the outside by a porous tube (outer frit). In some concepts the particle bed was held against the outer frit by centrifugal force by rotating the bed and frit. This was referred to as the rotating bed. In another concept referred to as the fixed bed the particles were held between an inner and outer frit. In both concepts coolant gas entered through the outer frit, flowed radially inward through the fuel particle bed where it was heated, and exhausted axially along the central void in the bed. Another variation of the particle bed reactor involved an array of discrete fuel elements consisting of an outer and inner frit, a bed of fuel particles and suitable end fittings to hold the assembly together. These fuel elements typically have a length to outside diameter ratio of four to one or larger whereas the initial rotating bed and fixed bed concepts generally had a ratio of about one to one.

During operation nuclear fuel elements present problems associated with growth of fuel particles during burnup and differential thermal expension and contraction of the particle bed and inner and outer frits. During changes in component temperatures differential thermal expansions or contractions may cause the fuel particle bed to undergo increased compression or, conversely, compressive loads may be removed, causing the bed to become loose. Excessive compressive loads could cause the fuel particles to fail by fracturing or the confining frits to distort. A loose bed may allow coolant gas to flow more freely through some areas than others, resulting in undesirable cold and hot spots within the fuel particle bed. A properly designed particle bed reactor fuel element must be able to accommodate specified changes in temperature and resulting differential expansions.

One design entails the removal of the combustion chamber and associated fuel injection and ignition equipment of a conventional turbine engine and employing a PBR in its stead. The PBR would have its central fuel element or its central fuel element and the first circle of fuel elements immediately adjacent to it removed so that a shaft of suitable material such as beryllium or carbon-carbon could be inserted in its/their stead. To this shaft would be connected the turbo compressor at the engine air intake end and the drive turbine at the exhaust end. In all other respects, the turbine engine itself would remain essentially the same. Such a modified engine would take in atmospheric air, compress it to a suitable pressure, heat the air in the PBR and eject it through a suitable exhaust system to produce thrust. It would eliminate the need for fossil fuel.

An air vehicle powered by PBR-heated air in a turbine engine will have virtually unlimited range and unlimited endurance. Such air vehicles can either be unmanned or manned. Manned vehicles will require shielding of personnel and /or cargo from neutron and gamma radiation escaping from the reactor, but an un-manned cruise missile would not.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|