Automated Ordnance Excavator (AOE)

The fielding of All-purpose Remote Transport System (ARTS) continued in 2000 with nineteen systems fielded to date. The ARTS provides Air Force security forces with a system to combat terrorist threats. At Nellis AFB, EOD personnel continue to use ARTS for range clearance of dangerous unexploded ordnance. The command and control system used for ARTS was expanded to robotically operate the Automated Ordnance Excavator (AOE). The AOE is a Caterpillar excavator that can be used to robotically excavate buried ordnance and remove it to a safe place for disposal. The first prototype system is being used by the Army Corp of Engineers to clear an old impact area at Camp Croft in Pacolet, SC.

In 1999, AFRL provided both training and the AOE to Jefferson Proving Ground for ordnance investigation and cleanup, reducing clearing costs from $47k to $6k a week. The Automated Ordnance Excavator (AOE) is a commercial excavator with an extended option to allow maximum distance between "bucket-to-machine," which is important when excavating buried ordnance. The current initiative is to have the system enter the target areas autonomously to locate buried ordnance. The airman will then operate the system by teleoperation in order to remove the buried ordnance.

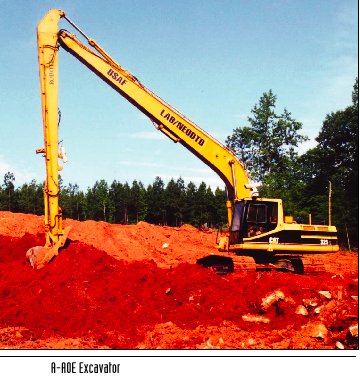

Advanced Automated Ordnance Excavator (A-AOE)

The Active Range Clearance (ARC) and Remediation System is a robotics research and development program managed by the Robotics Branch of the Air Force Research Laboratory, Tyndall Air Force Base, Florida. The Operational requirements for ARC development are found in the MNS for ARC, CAF 306-98.

The ARC program focuses on the application of unmanned systems to support and augment EOD personnel in their disposal of military munitions and removal of residue on DoD ranges. The program applies available and advanced technology and improved procedures/equipment to: (1) make the UXO ARC mission safer for range clearance personnel; (2) become more efficient by reducing both the range decontamination cost and the time required to perform decontamination; (3) significantly improve the range management process, and (4) meet the DoD objective to significantly reduce the risk of inadvertently transferring properties containing munitions items or hazardous constituents to the public.

The ARC will consist of a system of robotics platforms operating cooperatively. Current system equipment includes: (1) the Advanced Automated Ordnance Excavator (A-AOE); (2) Remote Sifter; (3) an ARTS, and (4) a Mobile Command Center. Initial efforts have focused on the A-AOE, a Caterpillar 325L excavator. This research involves the design and development of an automated robotic system to perform general excavation. The automated excavator will traverse the target area and locate itself in a position to retrieve buried ordnance or other hazardous items while allowing the operator to remain at a safe distance. Near-future developments include an automated digging capability, go-to-goal, and return-to-start positioning of the excavator bucket to facilitate routine movements.

This research effort is to develop technologies that can be integrated into an autonomous excavator. To accomplish this goal, technologies must be developed that address the essential mission elements. The development path for this technology is a four-step process: (1) automated digging; (2) independent boom/stick motion; (3) independent machine mobility, and (4) independent work planning and analysis. A contract has been awarded to Caterpillar, Inc. to develop the first stage technology, an Auto-dig Mission Planning Module (AMPM) for the A-AOE. The AMPM is a JAUS compatible electronics module that will take telemetry data from the A-AOE, process the data to calculate the boom, stick, and bucket motion paths, and return the motion commands to the A-AOE for execution.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|