AC-130U Spooky

Program

The acquisition program for the AC-130U gunship evolved from a Congressional mandate in the mid-1980s to revitalize the special operations force capabilties. In 1987, North American Rockwell began to modify the C-130 Hercules airframe, manufactured by the Lockheed Martin Aeronautics Company, for a new AC-130 gunship. Following the contract award to Rockwell in July 1987, the aircraft was first flown on 20 December 1990.

In the 1980s, the AC-130U Gunship Program Office, in what turned out to be a pioneering effort, developed its own warranty cost-benefit analysis methodology. The strengths of the in-house effort included the analysis' grounding in life cycle cost theory, involvement of functional area experts in its development and validation, and the foresight with which it was crafted. Its shortcomings included its failure to capture many of the relevant costs associated with the weapon system warranty, artificially-constraining assumptions, and a reliance on ultimately unobtainable data. The AC-130U Gunship warranty analysis effort highlighted many of the shortcomings that characterized the few existing tools: a requirement for non-existent data, the inherent difficulty in forecasting future costs, the difficulty of translating physical performance measures into terms of dollars and cents, and the specialized nature of available tools.

In FY92, procurement funding was increased to provide the 13th aircraft to replace the AC-130H lost during Operation Desert Storm. Upon completing an exhaustive flight test program at Air Force Flight Test Center between 1991 and 1994, the first aircraft was delivered to Air Force Special Operations Command on 1 July 1994. Boeing's contract included: concurrent development, aircraft production, flight test, and delivery. All aircraft had been delivered and the program transitioned to the sustainment phase. A competitive contract for sustainment was later awarded in July 1998.

The program office refocused its efforts on major modifications, mission area requirements, and operations and support. Besides streamlining their own efforts, the office shifted more of the workload to the prime contractor and other Air Force organizations. The program office used a Statement of Objectives for all new proposalas, eliminated all unnecessary material in the Request for Proposals (RFP) and pursued an electronic RFP process with Rockwell. Additionally, numerous test activites were transferred to the Special Operations Force's test unit at Hurlburt Field, Florida and more quality control actions were assigned to the DPRO.

In January 1996, the US Special Operations Command Acquisition Executive approved an acquisition strategy to conduct a testbed effort of a portion of the AC-130U Gunship Trainer. The testbed effort would be conducted by the Army Simulation, Training, and Instrumentation Command and would be followed by full and open competition for procurement of a full-up trainer. Research, Development, Test, and Evaluation and production costs for the AC-130U Gunship Trainer were estimated at $71.5 million from March 1996 through November 2000. The planned acquisition strategy for the trainer was seen as having the possibility to circumvent full and open competition. With operational requirements adequately defined, the need for a prototype or testbed effort was not justified. The funding profile was not appropriate for the planned acquisition strategy.

The 16th Special Operations Wing at Hurlburt Field received 2 additional AC-130U aircraft in mid-1996, giving the Wing a total of 12 AC-130U aircraft. This resulted in an increase of 87 full-time military manpower authorizations.

The Air Force, the Department of Justice, and the Boeing Company entered into a mediated settlement agreement with the assistance of an Armed Services Board of Contract Appeals (ASBCA) judge acting as a third-party neutral to settle the AC-130U Gunship Litigation. This major weapon system in litigation at the Court of Federal Claims was settled in 1998 through a structured negotiation Alternative Dispute Resolution process. The parties resolved contract claims and disputes valued at $785 million that had been unresolved for more than 10 years. The claims and disputes related to the contract awarded by the Department of the Air Force in 1987 for the design, development, integration, test, and production of 13 AC-130U Gunship aircraft. A structured process was used to analyze the claims; focus on cost, schedule, and performance issues; and isolate the matters in dispute. At the time, this was one of the largest contract claims ever resolved through an alternative dispute resolution process.

Although disputed matters between the parties remained unresolved for over `0 years, and had been the subject of intense litigation for 3 years preceding the Alternative Dispute Resolution attempt, the government team, consisting of the Air Force and the Justice Department, was able, with the assistance of Judge Martin Harty of the Armed Services Board of Contract Appeals serving as an independent third party mediator, to work with Boeing throughout a 6-month structured settlement process, to ultimately bring the matter to resolution with a settlement of all claims on the contract. Resolution of this dispute also required the work of dozens of people on both sides working full time over a 6-month period. An extensive support structure, which was needed to sort through the nearly 11 million pages of information used in the above Alternative Dispute Resolution. The Government team alone consisted of 150 people with an annual budget of $10 million. Noteworthy was the leadership exhibited by Air Force Brigadier General Frank Anderson, which was absolutely essential to the successful resolution of this matter.

The Naval Surface Warfare Center, Dahlgren Division (NSWCDD), on behalf of Air Force Special Operations Command (AFSOC) requested information in 2005 that was seen as having the possibility to lead to the acquisition and qualification of a family of 120mm mortar ammunition for enhancing the AC-130 Gunship Lethality and Survivability. Sources Sought Notice N00178-05-Q-1925 was posted on 18 August 2005 to Federal Business Opportunities (FBO). NSWCDD and AFSOC were seeking information on any (guided or conventional) 120mm mortar round that was fielded at that time, a Program of Record (POR) at that time, or technology mature enough to enter into an ACTD or similar demonstration.

The Naval Surface Warfare Center, Dahlgren Division (NSWCDD), on behalf of Air Force Special Operations Command (AFSOC) requested information in 2005 that was seen as having the possibility to lead to the acquisition and qualification of a family of 120mm mortar ammunition for enhancing the AC-130 Gunship Lethality and Survivability. Sources Sought Notice N00178-05-Q-1925 was posted on 18 August 2005 to Federal Business Opportunities (FBO). NSWCDD and AFSOC were seeking information on any (guided or conventional) 120mm mortar round that was fielded at that time, a Program of Record (POR) at that time, or technology mature enough to enter into an ACTD or similar demonstration.

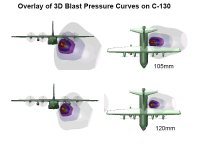

The 120mm mortar concept would offer benefits to the AC-130 fleet through: Employment flexibility through use of munitions currently available; Greater lethality through more fragmentation weight and greater blast damage; Precision strike capability; Increased standoff range and attack altitude while maintaining responsiveness; Reduction in collateral damage; and Reduction in danger close distance when supporting troops in contact.

For the existing 105mm gun, 100 rounds of ammunition weighed 4,200 pounds. The recoil load was about 10,900 pounds, with a gun recoiling weight of 1,465 pounds. The muzzle pressure was 3,560 pounds per square inch. It was a legacy system being phased out of the US Army inventory. There was little guided technology ongoing at the time the sources sought notice was issued. For the 120mm mortar, 100 rounds weighed 3,200 pounds. This weapon had a recoil Load of approximately 5,600 pounds with a gun weight of 1,315 pounds. The muzzle pressure was 1,620 pounds per square inch. This was the leading FCS fire support weapon and the Stryker Brigade Combat Team fire support weapon. There was a lot of guided munition development work ongoing for the system at the time of the sources sought notice was issued.

In FY13, work began on a sensor upgrade for the AC-130U. This was in response to an urgent requirement from US Special Operations Command (SOCOM) color electro-optical and infra-red (EO/IR) imaging at increased ranges for existing missions. The program would install non-developmental high-definition EO/IR sensors on the AC-130U fleet. Also in FY13, work began on the installation of the Beyond Line of Sight Ku Spread Spectrum (BLOS KuSS) High Speed Terminal T1 Mod and associated satellite antenna on both the AC-130U and older AC-130H aircraft. The systems were designed to support increased data transfer rate requirements when using existing C4ISR and enroute planning systems.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|