APPENDIX G

ADVANCED OPTICS AND LASERS

The newest systems greatly increase the night firing accuracy of all crew-served machine guns. They primarily enhance the gunner's ability to engage targets with great effectiveness to ranges of or beyond 1,000 meters. This appendix describes the AN/PAQ-4C, AN/PEQ-2A, laser systems. It also describes the AN/PAS-13 thermal sight and the M145 (MGO) telescope. Information for mounting, boresighting, and zeroing procedures for each weapon is also given.

Section I. ZERO PROCEDURES

An established day/night advanced marksmanship program equipped with training strategies and proposed qualification standards has been developed. Before beginning a night marksmanship program, soldiers must qualify on their assigned weapons during daylight conditions as outlined in the previous chapters of this manual and TMs. However, this appendix implements the new night qualification standards to compliment current Army training strategies. Commanders should follow these training strategies and abide by the qualification standards set forth to the best of their abilities. Although some courses of fire at first may seem redundant or inappropriate, numerous tests show that these training strategies work, and the qualification standards are achievable, if the strategy is followed.

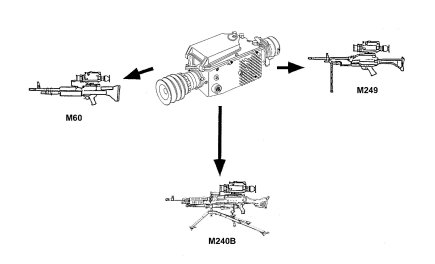

G-1. BORE LIGHT

The bore light is an accurate means of zeroing weapons and the most aided vision equipment without the use of ammunition. Time and effort are applied to ensure a precise boresight, which in turn saves time and ammunition. Table G-1 outlines weapon/aided vision device combinations that can be zeroed using the bore light with the M249/M60/M240B weapons. With optics, a 25-meter zero must follow boresighting. The precise boresighting of a laser allows the soldier to directly engage targets without a 25-meter zero.

|

M249 |

M60 |

M240B |

|

MGO |

X |

X |

X |

|

AN/PAQ-4C |

X |

X |

X |

|

AN/PEQ-2A |

X |

X |

X |

|

AN/PAS-13 |

X |

X |

X |

Table G-1. Weapon/aided vision device combinations.

a. Intent. Align the bore of the weapon to the optic, laser, or iron sight being fired to reduce or eliminate the time and ammunition it currently requires to live fire zero.

b. Special Instructions. Here are some special instructions the gunner should follow:

|

b. Observables. The gunner should do the following:

|

DANGERS

|

WARNINGS

|

G-2. CONCEPT

Boresighting is a simple procedure that can save time and ammunition only if the procedures outlined in this section are strictly followed. The bore light is a visible laser that is aligned with the barrel of the designated weapon. Then using a 10-meter offset, boresight the weapon with any optic, laser, or iron sight that you are assigned to fire. This procedure is accomplished by simply ensuring that the visible laser of the bore light is in line with the barrel by zeroing the bore light to the weapon, and then placing the visible laser of the bore light in a designated spot on the 10-meter offset. Once this procedure is accomplished, simply move the aiming point of the aiming device to the cross hair on the 10-meter offset. The weapon system is now boresighted and you are ready to engage targets or conduct a 25-meter zero. With optics, such as the MGO, TWS, and PVS-4, the bore light will put you on paper at 25 meters, thus reducing time and ammunition trying to locate rounds during the 25-meter zeroing. With lasers, the bore light allows you to boresight and then engage targets, eliminating the 25-meter zeroing procedures all together.

G-3. ZERO of BORE LIGHT TO WEAPON

Before boresighting the weapon system, make sure the bore light is first zeroed to the weapon. Take a flashlight and shine it through the barrel of the weapon and at 10 meters mark the spot that the flashlight is shining on. Then, without moving the weapon, fire one round. The impact of the round and the mark made with the flashlight should be the same. This procedure is the same principle used when zeroing the bore light to the weapon. This procedure is nothing more than aligning the visible laser with the barrel of the weapon, which would then hit the same area that the flashlight hit.

CAUTION

|

G-4. STABILIZE

Stabilization of the weapon is crucial. The weapon can be stabilized on a tripod or using the bipod as a field-expedient method. The weapon does not have to be perfectly level with the ground when boresighting the weapon. Every barrel is different; therefore, with every weapon, steps (d) through (f) must be done to ensure that the bore light is zeroed to that barrel. If the bore light is zeroed, then go directly to the boresighting procedures.

a. Attach the 5.56-mm or 7.62-mm mandrel to the bore light.

b. Insert the mandrel into the muzzle of the weapon. The bore light is seated properly when no further travel of the mandrel into the muzzle is permitted and the mandrel spins freely.

c. Stabilize the weapon so that it will not move. The commands of Start Point and Half Turn are given to ensure clear communication between the soldier by the weapon and the soldier by the offset.

(1) 10 Meters. 10 meters can be measured with the 10-meter cord that comes with the bore light or simply pace off eleven paces.

(2) Zeroing Mark. The zeroing mark (Figure G-1) is nothing more than a small dot drawn on a piece of paper, tree bark, or the bore light reference point on the 10-meter offset.

Figure G-1. Example of a zeroing mark.

(3) Start Point. Rotate the bore light until the battery compartment is facing upward and the adjusters are on the bottom. This position of the bore light and where the visible laser is pointing is identified as the start point (Figure G-2).

Figure G-2. Bore light in the START-POINT position.

(4) Half Turn. Rotate the bore light until the battery compartment is down and the adjusters are on top. This technique allows for easy access to the adjusters and helps with communication and stabilization of the weapon while conducting the boresighting procedures. This position of the bore light and where the visible laser is pointing is identified as the half turn position (Figure G-3).

Figure G-3. Bore light in the HALF-TURN position.

(5) Reference Point. The reference point is the point that is about half way between the start point and the half-turn point (Figure G-4).

Figure G-4. Example of a start point, half-turn point, and reference point.

e. Slowly rotate the bore light 360 degrees, while watching the visible laser made by the bore light. If the visible laser stops on the zeroing mark, the bore light is zeroed to the weapon.

f. If the bore light does not stop on the zeroing mark, then elevation and windage adjustments must be made to the bore light.

h. Repeat step g until the visible laser spins on itself.

G-5. BORESIGHT TARGET OFFSET

Appendix H shows the most current 10-meter boresight target offsets. The 10-meter boresight offset grids are 1-centimeter squares, unlike the 25-meter zero targets. Some boresight target offsets are not available at this print. For more information, contact the infantry proponent at C co, 2/29 IN at Fort Benning, GA. Stability of the weapon is crucial in boresighting. Place the weapon in the Bolt Forward position during boresighting procedures. Do not cant the weapon left or right during this process. Two soldiers (a firer and a target holder) are required to properly boresight a weapon.

a. Firer. The firer's primary duty is to zero the bore light and make all adjustments on the aided vision device being used.

b. Target Holder. The target holder secures the 10-meter boresight target straight up and down 10 meters from the bore light and directs the firer in making the necessary adjustments to the aiming device. The target holder must wear night vision goggles when boresighting infrared aiming lasers.

| NOTE: | Weapon stabilization is crucial, orientation is irrelevant. |

Section II. AN/PAQ-4C AIMING LIGHT

The AN/PAQ-4 aiming light projects an infrared laser beam, which cannot be seen with the naked eye but can be seen with night vision devices. This aiming light works with the AN/PVS-7B/C/D goggles and AN/PVS-14. The AN/PAQ-4C mounts on various weapons with mounting brackets and adapters.

G-6. EQUIPMENT DATA AND DESCRIPTION

The AN/PAQ-4 aiming light (Figure G-5) is activated by rotating the ON/OFF switch lever or the button on the optional cable switch. Either switch connects power from two AA batteries to an internal electronic circuit, which produces the infrared laser. Internal lenses focus the infrared light into a narrow beam. Rotating the mechanical adjusters with click detents controls the direction of the beam. These adjusters are used to zero the aiming light to the weapon. Once zeroed to the weapon, the aiming light projects the beam along the line of fire of the weapon. The optical baffle prevents off-axis viewing of the aiming light beam by the enemy.

a. Data. The AN/PAQ-4 aiming light includes the following equipment data:

|

Optics: |

100 percent parallax free, anti-reflective coated lens system. |

|

|

Length (sight): |

14 centimeters (5.5 inches) |

|

|

Weight: |

164 grams (5.78 ounces) |

|

|

Height: |

3 centimeters (1.2 inches) |

|

|

Width: |

6.5 centimeters (2.5 inches) |

|

|

Range: |

Beyond 600 meters. (Actual range depends on light level and night vision device used for observation.) |

|

|

Battery life: |

100-hour operating (ON) time for AA batteries in temperatures above 0 degrees centigrade (32 degrees Fahrenheit); 36-hours for temperatures below 0 degrees centigrade (32 degrees Fahrenheit). |

Figure G-5. AN/PAQ-4 aiming light.

c. M249 Machine Gun.

(1) Mounting Procedures. The gunner uses the AN/PVS-4 mounting bracket when mounting the AN/PAQ-4 on the M249 machine gun.

CAUTION

|

(a) Install the AN/PVS-4 mounting bracket by first placing the mounting bracket on top of the feed cover mechanism assembly so that the two forked ends are secured around the headless pins. Next, remove the screw cover behind the rear sight assembly, and screw the bracket knob in until it is tight.

(b) Install the bracket adapter (Figure G-6).

Figure G-6. Bracket adapter.

(c) Attach the AN/PAQ-4 on the bracket adapter (Figure G-7).

Figure G-7. Attaching bracket adapter to aiming light.

(d) Attach the AN/PAQ-4 to the AN/PVS-4 mounting bracket by first positioning the AN/PAQ-4 on top of the bracket so the spacer of the AN/PAQ-4 is aligned with the mounting knob of the bracket. Then, turn the mounting knob clockwise until the AN/PAQ-4 is tight.

WARNING

|

(2) Dismounting Procedures.

(a) Detach the AN/PAQ-4 from the AN/PVS-4 mounting bracket. Turn the mounting knob counterclockwise until the AN/PAQ-4 is loose. Remove the AN/PAQ-4 and spacer from the bracket.

(b) Remove the spacer from the AN/PAQ-4.

(c) Remove the AN/PVS-4 mounting bracket. Unscrew the bracket knob until the rear of the bracket is loose. Replace the screw cover behind the rear sight assembly. Remove the two forked ends from the headless pins and lift up on the mounting bracket to remove it from the feed cover mechanism assembly.

c. M60 Machine Gun.

(1) Mounting Procedures. The gunner uses the AN/PVS-4 mounting bracket when mounting the AN/PAQ-4 on the M60 machine gun.

CAUTION

|

(a) On the M60 machine gun bracket (Figure G-8), remove the M60 hinge pin latch and hinge pin from the over assembly by pressing on the latch (open end of pin) with an empty cartridge case, and separates the latch and pin. Place the pin and latch in the aiming guides on the left side of the mounting bracket and press together.

(b) Position the mounting bracket assembly on top of the machine gun cover so that the holes in the front of the bracket align with the cover assembly pinholes.

(c) Insert the longer hinge pin supplied with the bracket through the bracket and cover assembly, and secure it by inserting the hinge pin latch.

(d) Loosen the wing nuts on both leg clamps and positions the clamps under the cover assembly. Secure the mounting bracket by tightening the wing nuts firmly. Place the split washer is placed next to the wing nut and the flat washer is placed next to the bracket.

Figure G-8. Installation of M60 mounting bracket.

(f) Install the sight on the M60 mounting bracket assembly by positioning it in the groove on top of the bracket so that the scribe line on the bracket is aligned with the scribe line on the sight-mounting adapter. Tighten the lever screw assembly to secure the sight to the bracket. Use an empty cartridge case placed over the lever arm to increase leverage as the screw is tightened.

(2) Dismounting Procedures.

(a) Unscrew the lever screw assembly by turning it counterclockwise and remove the AN/PAQ-4 from the mounting bracket. Use an empty cartridge case placed over the lever arm for increased leverage if necessary.

(b) Loosen the wing nuts on both leg clamps.

(c) Push down on the longer hinge pin latch with an empty cartridge case and remove the hinge pin and latch.

(d) Remove the mounting bracket from the machine gun.

(e) Remove the M60 hinge pin and latch from the left side of the bracket by pushing on the hinge pin latch and pulling out the hinge pin.

(f) Replace the M60 hinge pin and latch.

(g) Remove the batteries when storing the sight.

d. M240B Machine Gun.

(1) Mounting Procedures. Before zeroing and qualifying with the AN/PAQ-4, the gunner must mount the sight onto his weapon. The M240B machine gun has a rail mount already attached to the cover assembly.

(a) Install the sight on the M240B rail mount by loosening the mounting knob located on the left side.

(b) Position the sight in a slot on the rail mount. Any slot can be used as long as the mount does not hang over the edge of the rail.

(c) Hand tighten the knob (clockwise) on the mount until a clicking noise is heard (two clicks).

(d) Places the sight in the same slot after zeroing to ensure that the sight retains its zero.

WARNING

|

(2) Dismounting Procedures. Loosen the mounting knob on the left side of the bracket, then lift up on the sight to remove it from the M240B machine gun.

(a) Adjust the bore light, if necessary. Move the target to a distance of 2 meters. Mark the location of the laser dot. Slowly rotate the bore light one half turn. Note the new location of the laser dot. Adjust the windage and elevation until the laser dot moves halfway back to its original location. Continue the procedure until the laser dot remains stationary (or spins upon itself within 1 centimeter) when the bore light is rotated. Move the target to a distance of 10 meters and recheck the boresight.

(b) Boresight the AN/PAQ-4 to the weapon. Select the target (boresight offset) for the appropriate weapon and the AN/PAQ-4. Position the weapon so the bore light strikes the small dot on the boresight target. Zero the AN/PAQ-4 by turning both windage and elevation knobs (for the pointer and illuminator) fully clockwise until they stop. Rotate counterclockwise three turns and align the white dot on the adjuster with the center of the front adjuster flange (Figure G-9).

Figure G-9. Adjuster alignment.

G-7. Boresight and Zero Procedures

The following procedures are used to boresight and zero the M249, M60, and M240B machine guns using the AN/PAQ-4C aiming light.

a. Boresight. Check the alignment of the bore light.

(1) Place the appropriate mandrel with the bore light attached in the muzzle of the weapon.

(2) Turn on the bore light so that the laser dot strikes the target (offset) 10 meters away.

(4) If the dot remains stationary, the laser is boresighted. Go to step 3 and use the appropriate boresight target for the weapon being boresighted.

(5) If the dot rotates in a circle, adjust the windage, elevation, or both until the dot remains stationary or rotates on itself no more than 1 cm. Go to step 2.

b. 25-Meter Zero. The gunner chooses the appropriate strike zone from TM 11-5855-309-12 P, and draws it on the 25-meter zero target. He follows the procedures above and zeroes the weapon with the AN/PAQ-4. He fires a total of three rounds (one at a time) before triangulating the shot group. Once the weapon is zeroed on the 25-meter zero range, the gunner follows the procedures outlined below for field zeroing to obtain an accurate zero.

c. Field Zero. If the adjustment screws are turned too far, they will break. If the laser is side-mounted, the elevation and windage knobs will switch roles.

(1) Assume a good prone bipod-supported position. Fire a seven-round burst at the target. Note the burst pattern on the ground in relation to the target.

(2) Correct for windage (if rounds are impacting to the right or left of the target). Note that each click of the windage knob sight moves the group on the target mil (1/2 mil equals 6 inches at 300 meters or 10 inches at 500 meters).

(3) Correct for elevation (if rounds are impacting over or short of the target).

After making corrections on the sight, fire a confirming burst. If the target is not hit with the confirming burst, repeat the above procedures. Treat each subsequent burst as if it were the initial burst.

(2) Prepare the sight for field zeroing and check the sight. The preferred range is 300 meters.

G-8. Training Strategies

Two training strategies have been devised to adequately train soldiers in the use of the infrared aiming laser devices. The night initial training strategy is used for soldiers who have little or no previous experience with night vision goggles or with units beginning a night training program. The night sustainment training strategy is for soldiers who are familiar with night vision goggles and with units who have already implemented a night training program. The night initial training strategy is conducted over a two- to three-day time frame and consists of the following:

a. Day 1.

(1) Night Vision Goggles Training With Terrain Walk When Firing Aiming Lasers. Soldiers are given in-depth instruction on the proper use and fit of night vision goggles, to include characteristics and capabilities, maintenance, and mounting procedures. At night, soldiers conduct a terrain walk to become more familiar and build confidence using the night vision goggles.

(2) Aiming Device Training. Soldiers receive familiarization training on the aiming device. This training covers operation and characteristics, maintenance procedures, and mounting procedures.

(3) Fundamentals of Firing. This includes body position, foxhole, and prone. Soldiers review and practice firing positions and fundamentals of marksmanship and any changes that occur when using this aiming device.

b. Day 2 to 3.

(1) Weapon and Equipment. Inspect the weapon and aiming device to ensure the aiming device is mounted securely to the weapon. A review of clearing or misfire procedures is important. Let the soldiers use dummy rounds to practice correcting malfunctions with their eyes closed or during limited visibility.

(2) Boresight Aiming Device to Weapon. Each soldier boresights the weapon and aiming device at a range of 10 meters. If a bore light is not available, then 25-meter zero the weapon and sight by using the specified zeroing procedure for that weapon/sight combination. For course of fire, refer to Table 4-4 in Chapter 4 for a description of the aiming laser and AN/PVS-4 firing table. MGO and TWS will fire the day qualification table.

c. Field Fire I. Perform dry-fire exercise with no ammunition:

(1) Assume a stable, prone firing position. Fire the weapon maintaining sight alignment and sight picture. Pull the trigger correctly by pulling straight to the rear and releasing the trigger. Pull the trigger to the rear and say to yourself, "fire a burst of seven." After the word "seven," let go of the trigger.

(2) Apply correct traversing and searching techniques. Traversing means moving the muzzle of the weapon to the left or to the right to distribute fire laterally. Shift the shoulder slightly to the right or left for minor changes. For major changes, move the elbows and align the body directly behind the weapon. Searching means moving the muzzle of the weapon up or down to distribute fire in depth. To make changes in elevation, move the elbows closer or farther apart.

(3) The following targets are used for field fire I:

|

d. Field Fire II. Perform a timed, dry-fire exercise on a transition range. This familiarizes the gunner with acquiring targets on a timed exercise. It also allows the soldier and the point safety time to make any corrections on-sight, or the body position and grip before the qualification table.

(1) Assume a stable, prone firing position. Fire the weapon maintaining sight alignment and sight picture. Pull the trigger correctly. Pull straight to the rear and release. Pull the trigger to the rear and say to yourself, "fire a burst of seven." After the word "seven," let go of the trigger.

(2) Apply correct traversing and searching techniques. Traversing means moving the muzzle of the weapon to the left or to the right to distribute fire laterally. Shift the shoulder slightly to the right or left for minor changes. For major changes, move the elbows and align the body directly behind the weapon. Searching means moving the muzzle of the weapon up or down to distribute fire in depth. To make changes in elevation move the elbows closer or farther apart.

(b) The following targets are used for field fire II:

|

e. Night Record Qualification. Perform live-fire exercises with ammunition. Engage targets on a transition range timed. This exercise measures the gunner's ability to engage targets during a timed exercise (154 rounds of A064 4x1 mix 5.56-mm linked M249, 154 rounds of A131 4x1 mix 7.62-mm linked M60 and M240B):

(1) Assume a stable, prone firing position. Fire the weapon maintaining sight alignment and sight picture. Pull the trigger correctly. Pull straight to the rear and release. Pull the trigger to the rear and say to yourself, "fire a burst of seven." After the word "seven," let go of the trigger.

(2) Apply correct traversing and searching techniques. Traversing means moving the muzzle of the weapon to the left or to the right to distribute fire laterally. Shift the shoulder slightly to the right or left for minor changes. For major changes, move the elbows and align the body directly behind the weapon. Searching means moving the muzzle of the weapon up or down to distribute fire in depth. To make changes in elevation move the elbows closer or farther apart.

(3) Use observation and adjustment of fire. Observe machine gun fire by noting the strike of the projectiles in the target area. When firing the bipod-mounted gun, adjust fire by changing body position.

(4) Apply the adjusted aiming point method. The adjusted aiming point method is a means of rapidly and accurately adjusting fires without making sight adjustment. If the initial burst misses the target, select a new aiming point on the ground. The aiming point should be the same distance from the target as the initial burst's center of impact.

(5) The following targets are used for night record qualification with the AN/PVS-4 and the aiming lasers. TWS and MGO will fire the day record fire table:

|

Section III. AN/PEQ-2A TARGET POINTER/

ILLUMINATOR/AIMING LIGHT

The AN/PEQ-2A target pointer/illuminator/aiming light (TPIAL) (Figure G-11) is a Class IIIB laser that emits a highly collimated beam of infrared light for precise aiming of the weapon as well as a separate infrared illuminating beam with adjustable focus. A safety block is provided for training purposes (blue side), which limits the operator from selecting the high power modes (black side).

G-9. Description

This paragraph gives a description of the AN/PEQ-2A along with its accessories (Figure G-10). This paragraph also describes how to install and operate the AN/PEQ-2A. The TPIAL projects an infrared laser beam that cannot be seen with the eye but can be seen with night vision devices. It is capable of projecting a much wider infrared illuminating beam from an integral illuminator. The TPIAL works with night vision goggles and mounts on various weapons with mounting brackets and adapters. Leaders use the AN/PEQ-2A in the hand-held mode to illuminate and designate targets.

a. Data.

|

Weight: |

7.5 ounce (with 2 AA batteries) |

|

|

Length: |

16.26 centimeters (6.4 inches) |

|

|

Width: |

7.12 centimeters (2.8 inches) |

|

|

Height: |

3.05 centimeters (1.2 inches) |

|

|

Range: |

600 meters in low power (eye safe) |

|

|

2,000 meters in high power (non-eye safe) |

||

|

Output Power: |

||

|

Aiming laser |

25 meters wide (+- 10 percent) |

|

|

Illuminator |

30 meters wide (+50, -20 percent) |

|

|

Beam Divergence: |

||

|

Aiming laser |

5 meter rad |

|

|

Illuminator |

1.0 to 115 meter rad |

|

|

Batteries: |

Two 1.5-volt AA batteries |

b. Components. (See Figure G-10.)

Figure G-10. AN/PEQ-2A with accessories.

(1) TPIAL assembly with safety block.

(2) Rail.

(3) Neck cord.

(4) Textile bag.

(5) Cable switch, 12-inch, membrane.

(6) Operator's manual.

(7) Batteries 1.5V AA.

(8) Strap, retention.

(9) Cable Switch, 20-inch, button.

(10) Bracket Adapter.

(11) Training extender (Army only).

(12) M4/M16A2 bracket assembly.

G-10. OPERATION

This paragraph describes how to operate the AN/PEQ-2A, to include battery installation, safety block installation, the button switch, the cable switch, the mode switch, and boresight adjusters.

a. Battery Installation (Figure G-11). Unscrew the battery caps and install two AA batteries. Orient the batteries as indicated by the markings on the AN/PEQ-2A body.

Figure G-11. AN/PEQ-2A battery installation.

b. Safety Block Installation (Figure G-12). The safety block installed in the training mode (blue side up) prevents the operator from accessing the non-eye safe modes (AIM HI, DUAL LO/HI, DUAL HI/HI). A .050 hex head Allen wrench is needed to unscrew the block from the body and reinstall it in the tactical mode (black side up).

Figure G-12. Safety block installation.

c. Mode Selector. The mode selector is used to set the mode in which the AN/PEQ-2A operates when the cable-switch button or the push button is depressed. The mode selector has six positions (Table G-2).

|

KNOB POSITION |

OPERATION |

|

0 |

The AN/PEQ-2A does not operate. |

|

1 |

The aiming beam operates at low power. |

|

2 |

The aiming beam operates at low power and the illuminating beam operates at low power. |

|

3 |

The aiming beam operates at high power. |

|

4 |

The aiming beam operates at low power and the illuminating beam operates at full power. |

|

5 |

The aiming beam operates at high power and the illuminating beam operates at full power. |

Table G-2. Mode selector positions.

d. Button Switch (Figure G-13). The button switch is used when the AN/PEQ-2A is hand held. Pressing the button switch operates the AN/PEQ-2A in the operational mode set by the mode selector. When the button is released, the AN/PEQ-2A turns off. A green LED is incorporated into the body of the AN/PEQ-2A to indicate that the AN/PEQ-2A is ON. Whenever the AN/PEQ-2A is activated, the green LED lights and stays lit until the unit is turned OFF. If continuous operation of the AN/PEQ-2A is desired, pressing the button switch twice in rapid succession latches the AN/PEQ-2A to ON. The AN/PEQ-2A remains on until the push button is pressed a third time.

Figure G-13. Operation of the button switch.

e. Cable Switch. The cable switch (Figure G-14) is used when the AN/PEQ-2A is mounted on a weapon. The switch plugs into the back of the AN/PEQ-2A assembly. Pressing the button or pad at the end of the cable switch causes the AN/PEQ-2A to turn on in the operational mode selected by the mode select switch. When the button is released, the AN/PEQ-2A turns off. If continuous operation of the AN/PEQ-2A is desired, pressing the cable switch twice in rapid succession latches the AN/PEQ-2A to ON. The AN/PEQ-2A remains on until the push button is pressed a third time. When the cable switch plug is installed in the AN/PEQ-2A, it automatically locks into place. To remove the switch, pull back on the plug sleeve and pull the plug out. DO NOT TRY TO REMOVE THE PLUG BY PULLING ON THE CABLE.

Figure G-14. Installation of the cable switch.

f. Focus Knob (Figure G-15). The focus knob is used to vary the spread of the illumination beam based on the range and size of the area to be illuminated.

Figure G-15. Using the focus knob.

g. Lens Cap (Figure G-16).

(1) The black lens cap blocks the AN/PEQ-2A illuminator or aiming laser beam should the device be activated. To use the black lens cap, pull it from its stored location on the side of the AN/PEQ-2A and stretch it over the front of the focus knob or aiming beam so that it fits snugly in place.

(2) The diffuser lens cap enables the illuminator or aiming laser to emit in a 45-degree cone (10 feet at 10 feet). To use the diffuser lens cap, pull it from its stored location on the side of the AN/PEQ-2A and stretch it over the front of the focus knob or aiming beam so that it fits snugly in place.

(3) The neutral density lens cap enables the AN/PEQ-2A illuminator or aiming laser to be operated in low power. To use the neutral density lens cap, pull it from its stored location on the side of the AN/PEQ-2A and stretch it over the front of the focus knob or aiming beam so that it fits snugly in place.

Figure G-16. Installing the lens caps.

h. Adjusters (Figure G-17). The AN/PEQ-2A is equipped with boresight adjusters for zeroing the aiming beam and illumination beam. The AN/PEQ-2A adjusters move the beams in true horizontal and vertical directions. When zeroing the AN/PEQ-2A, it is best to zero the aiming beam to the weapon and then align the illumination beam to the aiming beam.

Figure G-17. Boresight adjusters for both aiming and illumination beams.

G-11. Mount/dismount procedures

This paragraph describes the mounting procedures for the AN/PEQ-2A (M249, M60, M240B). Reverse the procedures to dismount the AN/PEQ-2A.

a. TWS Mounting Bracket. (See Figure G-18.)

(1) Attach the rail grabber (3) (P/N 12598120) to the AN/PEQ-2A (4).

(2) Loosen the knob on the AN/PEQ-2A rail grabber.

(3) Select the slot on rail (5) for mounting. Any slot may be used as long as the mount does not hang over the edge of the rail.

(4) Place the bar of the rail grabber (3) in the slot of the rail (5) and hand tighten the knob on mount until a clicking noise can be heard.

Figure G-18. Mounting the AN/PEQ-2A

to the M249 using TWS bracket.

b. M60 Machine Gun.

(1) Remove the M60 hinge pin latch and hinge pin from the cover assembly. Place the pin latch in the aiming guides on the left side mounting bracket and press together.

(2) Place the mounting bracket on top of the machine gun cover so that the holes in the front of the bracket align with the cover assembly pinholes.

(3) Insert the longer hinge pin supplied with the bracket through the bracket and cover assembly and secure by inserting the hinge pin latch.

(4) Turning counterclockwise loosen the wing nuts on both leg clamps and position the leg clamps under the cover assembly. Secure the mounting bracket by tightening the wing nuts firmly. The split washer should be next to the wing nut and the flat washer next to the bracket.

(5) Place the bracket adapter in the AN/PEQ-2A mounting groove flush with the front of the AN/PEQ-2A. Tighten the thumbscrew clockwise.

(6) Position the AN/PEQ-2A with the bracket adapter on the M60 mounting bracket mounting groove. Align the front edge of the bracket adapter and the front edge of the groove. Tighten the lever screw assembly (Figure G-19).

Figure G-19. Mounting the AN/PEQ-2A to the M60 machine gun.

c. M240B Machine Gun.

(1) Mount the AN/PEQ-2A 1 on the top cover rail (see arrow) using the AN/PEQ-2A bracket adapter and a standard rail grabber. The unit armorer preassembles the rail grabber and the bracket adapter.

(2) Mount the bracket adapter to the AN/PEQ-2A using the thumbscrew on the AN/PEQ-2A.

(3) Loosen the clamping knob until the rail grabber has sufficient space to fit over the top cover rail. Tighten the clamping knob until two clicks are heard.

(4) Place the AN/PEQ-2A at a position on the rail that is the most convenient for the operator. If however the AN/PEQ-2A is removed from the rail, the operator must take note of the position at which the device was zeroed, and then return the device to the same position to ensure the zero is retained.

(5) Install the remote switch in a convenient location using the provided cable hangers (Figure G-20).

Figure G-20. Mounting the AN/PEQ-2A to the M240B machine gun.

WARNING

|

(6) To dismount the devices for each weapon, reverse the procedures.

G-12. Fundamentals of Marksmanship

The fundamentals of machine gun marksmanship for the M249, M60 and M240B machine guns are the same as with the AN/PAQ-4 (paragraph G-7). To use the maximum effective range of the AN/PEQ-2A, the safety block must be removed and the AN/PEQ-2A placed in high power. Because the laser is non-eye safe in the tactical mode (high power), batteries for the AN/PEQ-2A are issued to the firers on the firing line only when the weapon is oriented down range.

a. Boresight Procedures. Follow the procedures outlined in paragraph G-6 to boresight the machine gun and the AN/PEQ-2A.

b. Zero Procedures. Follow the procedures outlined in paragraph G-6 to zero and field zero the machine gun and the AN/PEQ-2A. (Refer to TM 11-5855-308-12&P for further information on zeroing procedures and zeroing targets with designated strike zones.)

c. Sight Adjustments. Sight adjustments for the aiming light and illuminator beam are the elevation adjustment screw (1 click at 25 meters equals 4 millimeters) (clockwise equals up) and the windage adjustment screw (1 click at 25 meters equals 4 millimeters) (clockwise equals right).

(1) The adjustment screws will break if they are turned too far.

(2) If the laser is side-mounted, the elevation and windage knobs will switch roles.

G-13. Training Strategies

Training strategies are the same for all weapons that use the AN/PAQ-4 except for the use of the illuminating beam. The illuminating beam allows soldiers to detect targets at ranges up to 2,000 meters (dependent upon terrain and weather constraints) in the high-power mode (tactical mode). Remember that the laser is not eye-safe in the tactical mode. In the low-power mode, targets can be engaged out to 600 meters during ideal limited visibility conditions (for example, 75 percent illumination, no rain or fog). The tactical mode should only be used on the M60 machine gun, and M240B machine gun.

Section IV. AN/PAS-13 (V2) MEDIUM

WEAPON THERMAL SIGHT

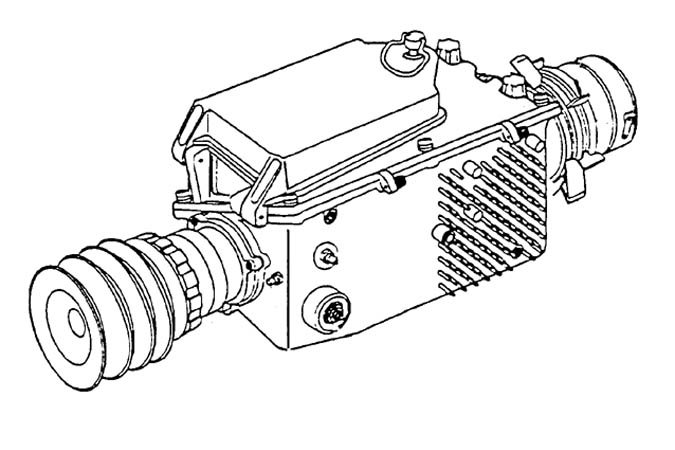

The AN/PAS-13 (V2) medium-weapon, thermal sight (MWTS) (Figure G-21) is silent, lightweight, compact, and durable battery-powered thermal imaging sensors that operate with low battery consumption.

Figure G-21. Model of the medium-weapon thermal sight.

G-14. description

The MWTS is capable of target acquisition under conditions of limited visibility such as darkness, smoke, fog, dust, and haze. The MWTS operates at night and during the daytime. Infrared light is received through the telescope, detected by an IR sensor, converted to digital data, processed, and then displayed for the user. The MWTS is composed of two functional groups: the telescope and the basic sensor.

a. Telescope. The telescope receives IR light emitting from an intended target and its surroundings. The telescope magnifies and projects the IR light on the scanner on the basic sensor (Figure G-22).

Figure G-22. MWTS configurations.

b. Basic Sensor. The scanner reflects the IR light received from the telescope on the detective assembly. The detective assembly senses the IR light and converts it to video. The sensor's electronics condition the video for display on the LED array. The LED array illuminates the IR image along with the reticle. The light from the LED array is reflected off the scanner to form an image at the eyepiece. The only difference between the MWTS and the HWTS are the telescopes, which are different magnifications and hold different reticles. The basic sensor on the two models is the same. The MWTS fits the M249, M60, and the M240B machine gun. (Figure G-23).

Figure G-23. Medium-weapon thermal sight.

c. Data. The following is the equipment data for the medium-weapon thermal sight.

|

|

Narrow— 9 degrees |

|

|

Wide— 15 degrees |

|

|

Narrow FOV— 3.3X |

|

|

Wide FOV— 2X |

|

|

ON mode— 12.0 watts |

|

|

STANDBY mode— 5.5 watts |

|

|

71 percent STANDBY mode— 10 hours |

|

|

EMERGENCY mode— 3.5 hours |

G-15. OPERATION

The MWTS has three modes of operation: STANDBY, ON, and EMERGENCY. Figure G-24, shows controls and indicators.

a. Modes.

(1) STANDBY Mode. When the system is first turned on, the MWTS begins a cool-down period of about 2 minutes. After the cool-down period, the MWTS enters the STANDBY mode. During the STANDBY mode, power is not applied to the scanner or display to extend the life of the battery.

(2) ON Mode. When the MWTS is in the STANDBY mode and pressure is applied to the eyecup, the MWTS switches to the ON mode, and a switch engages to provide power to the scanner and display. After a three-second delay, the system is fully operational.

(3) EMERGENCY mode. When switched to the EMERGENCY mode, the MWTS continuously applies power to the entire system. This mode allows the operator to bypass the 3-second delay experienced when switching from the STANDBY to the ON mode. Since power is applied to the entire system while in the emergency mode, battery life is greatly reduced.

b. Controls and Switches.

(1) The CONTRAST CONTROL (1) adjusts the contrast of the thermal scene. When turned fully clockwise to AUTO, contrast is automatically set.

(2) The EMERGENCY CONTROL (2) overrides the eyecup switch and turns entire system on, which places the MWTS in the EMERGENCY mode.

(3) The BRIGHTNESS CONTROL (3) is a nine-position rotary switch with an off detent position (turned fully counterclockwise). The purpose is to turn the system on or off and adjust the brightness of the eyepiece display.

(4) The FOCUS RING (4) adjusts the telescope focus from 20 meters to infinity. It requires a manual adjustment and affects both the wide and narrow fields of view.

(5) The FIELD OF VIEW RING (5) is located on the telescope. It has a wide and a narrow field of view. The wide FOV is for using low magnification during target detection, and the narrow FOV is for using high magnification during recognition and engagement.

(6) The RETICLE SELECT SWITCH (6) selects one of the available reticles depending on the MWTS model (medium or heavy). It must be held for 2 seconds to enable reticle changes. After 2 seconds, release the switch to cycle to the next reticle. This control is disabled after 10 seconds of inactivity.

(7) The RETICLE ADJUST SWITCH (7) adjusts the reticle aiming features in azimuth and elevation. It is used during zeroing, and it must be held for 2 seconds to allow changes to be made. After 2 seconds, each press moves the reticle aiming features one increment. This control is also disabled after 10 seconds of inactivity.

(8) The BLACK/WHITE POLARITY SWITCH (8) selects the polarity of the thermal image displayed on the raster. The initial setting is WHITE HOT. The polarity switch affects the appearance of the target.

(9) The EYECUP (9) controls STANDBY/ON when the system is on. When forward pressure is applied to the eyecup, the system is in the ON mode. When the pressure is removed for longer than 30 seconds, the system returns to the standby mode.

(10) The DIOPTER FOCUS RING (10) adjusts the focus of the raster and indicators to the operator's eye. It ranges from +2 to -6 diopters.

Figure G-24. MWTS controls and indicators.

c. Eyepiece Indicators (Figure G-25). Eyepiece indicators illuminate as follows:

(1) NOT COOL (11) when the detectors are not cool enough for proper operation.

(2) WHT HOT/BLK HOT (12) polarity.

(3) EMER (13) during emergency mode operation.

(4) LOW (14) when battery power has about 15 minutes of useful power left with go-to-war batteries.

(5) RETICLE SELECT/FOV (15) identifies which reticle is currently selected and indicates wide FOV or narrow FOV as selected by the FOV.

(6) ELEVATION INDICATOR (16) indicates the elevation zeroing adjustment of the reticle. It also displays the number of increments the reticle is UP (U) or (D) DOWN from the center zero position.

(7) NFOV/WFOV (17) indicates wide FOV or narrow FOV.

(8) ZOOM (18) indicates the zoom mode is selected.

(9) RET ADJ (19) indicates the reticle adjustment mode is selected.

(10) RET SEL (20) indicates the reticle select mode is selected.

(11) AZIMUTH INDICATOR (21) indicates the azimuth zeroing adjustment of the reticle. It also displays the number of increments the reticle is left (L) or right (R) from the center zero position.

(12) SENSOR COOLING (22) is displayed when the power is turned on, the indicator displays about a 2-minute cool-down period. After cool-down, the current reticle is displayed.

(13) The COOLDOWN PERIOD INDICATORS blink the first 10 seconds after the system is turned on. After 10 seconds, the NOT COOL indicator is lit and the POLARITY, EMERGENCY, and LOW BATTERY indicators function normally. The DISPLAY RASTER displays the thermal image with a superimposed reticle.

Figure G-25. Eyepiece indicators.

CAUTION

|

d. M249 Machine Gun.

(1) Mounting Procedures. Before zeroing and qualifying with the AN/PAS-13, the gunner must mount the sight on the weapon (Figure G-26).

(a) Open the cover of the weapon.

(b) Rotate the hook-retaining pin downward (over the top of the hinge pin) and remove the retaining clip from the left side of the hinge pin.

(c) Remove the weapon's hinge pin. Do not lose the retaining clip.

Figure G-26. Mounting the MWTS on the M249.

(d) Remove the retaining clip from the M249 mounting bracket (Figure G-27).

(e) Remove the MWTS hinge pin from the mounting bracket and replace it with the M249 hinge pin (Figure G-28). Secure it to the mounting bracket by replacing the retaining clip (the one from the mounting bracket).

Figure G-27. M249 bracket.

Figure G-28. M249 hinge pin replacement.

(f) Replace the cover of the M249 so that the slot in the cover lines up with the holes in the receiver group.

(g) Push the MWTS hinge pin through the slot and the spring.

(h) Secure the MWTS hinge pin by rotating the hook-retaining pin upward (over the hinge pin) and replacing the retaining clip on the left side of the pin. Close the cover of the weapon.

(i) Place the grooves on the front of the bracket over the edges of the MWTS hinge pin and rotate the bracket downward onto the cover. Ensure that the thumb wheel on the rear of the mounting bracket lines up with the threaded hole on the cover of the weapon.

(j) Secure the mounting bracket to the cover by tightening the thumbscrews and the thumb wheel.

(k) Select a slot on the rail of the bracket and place the bar of the MWTS mount in the slot. Hand-tighten the knob on the MWTS mount until it clicks at least twice.

(2) Dismounting Procedures.

(a) Loosen the knob on the MWTS mount until it is free of the rail and remove the MWTS.

(b) Unscrew the thumb wheel and thumbscrews and remove the mounting bracket from the weapon.

(c) Open the cover of the weapon and remove the retaining clip from the MWTS hinge pin.

(d) Rotate the hook-retaining pin downward (over the top of the hinge pin) and remove the MWTS hinge pin.

(e) Remove the M249 hinge pin from the mounting bracket and replace it with the MWTS hinge pin. Secure it with the MWTS retaining clip.

(f) Place the cover of the M249 on top of the weapon, aligning the holes in the cover with the slot in the receiver.

(g) Replace the M249 hinge pin to the weapon.

(h) Secure the M249 hinge pin by replacing the retaining clip and rotating the hook-retaining pin upward (over the top of the hinge pin).

CAUTION

|

e. M60 Machine Gun.

(1) Mounting Procedures. Before zeroing and qualifying with the AN/PAS-13, the gunner must mount the sight on the weapon (Figure G-29).

(a) Loosen the clamping bars all the way on the MWTS mounting brackets by turning the thumb wheels.

(b) Loosen the locking nuts on the front of the MWTS mounting bracket (Figure G-30).

(c) Open the feed tray cover of the M60 and remove the M60 hinge pin and hinge pin latch (Figure G-31).

Figure G-29. Mounting the MWTS on the M60.

Figure G-30. M60 bracket.

Figure G-31. M60 hinge pin replacement.

(d) Remove the MWTS hinge pin and hinge pin latch from the M60 mounting bracket.

(e) Place the MWTS hinge pin and hinge pin latch through the holes in the feed tray and feed tray cover to secure them to the M60.

(f) Insert the hinge pin (the larger pin) from the left side of the gun. Insert the hinge pin latch (the smaller pin) from the right.

(g) Place the M60 hinge pin and hinge pin latch into the hinge pin holder on the MWTS mounting bracket.

(h) Place the pins on the inside front of the MWTS mounting bracket over the holes in the hinge pin and hinge pin latch.

(i) Place the clamping bars so that the grooves in them fit under the lip of the feed tray cover.

(j) Tighten the locking nuts by hand and tighten the clamping bars by rotating the thumb wheels.

(k) Select a slot on the rail of the bracket and place the bar of the MWTS mount in the slot.

(l) Hand tighten the knob on the MWTS mount until it clicks at least twice.

(2) Dismounting Procedures.

(a) Loosen the mounting knob located on the left side of the MWTS mount until it is free of the rail and remove the MWTS.

(b) Unscrew the thumb wheels and locking nuts and remove the mounting bracket from the weapon.

(c) Open the cover of the weapon and remove the MWTS hinge pin.

(d) Remove the M60 hinge pin from the mounting bracket and replace it with the MWTS hinge pin. Secure it with the retaining clip.

(e) Place the cover of the M60 on top of the weapon, aligning the holes in the cover with the slot in the receiver.

(f) Replace and secure the M60 hinge pin to the weapon.

CAUTION

|

f. M240B Machine Gun.

(1) Mounting Procedures. Before zeroing and qualifying with the AN/PAS-13, the gunner must mount the sight on the weapon. The M240B machine gun has a rail mount already attached to the cover assembly.

(a) Install the sight on the M240B rail mount by loosening the mounting knob located on the left side.

(b) Position the sight on the rail mount by placing the bar of the mount in a slot on the rail and hand tighten the knob on the mount until two clicks are heard. Any slot can be used as long as the mount does not hang over the edge of the rail (Figure G-32).

WARNING

|

Figure G-32. Mounting the ANPAS-13 to the M240B.

(2) Dismounting Procedures.

(a) Unscrew the mounting knob on the left side.

(b) Lift up on the sight to remove it from the M240B machine gun.

g. Boresighting Procedures. Follow the instructions to boresight the weapon as outlined in TC 23-AIMSS. Choose the correct reticle for the weapon by pressing the reticle select switch for 2 seconds. Then scroll through the reticles until the correct one is found. Follow the instructions for boresighting the MWTS on the boresight target offset. Adjust the aiming point until the red dot is centered on the cross hair on the offset. You must boresight in both the narrow FOV and wide FOV.

h. Zeroing Procedures. Refer to TM 11-5855-309-12&P for zeroing procedures for the M249, M60, and M240B machine guns.

g-16. Training Strategies

The training strategies for the 5.56-mm and 7.62-mm caliber weapons with the MWTS are the same as with the AN/PVS-4 (as outlined in paragraph G-8) for both the night initial and night sustainment training strategies.

Section V. M145 STRAIGHT TELESCOPE (MGO)

The M145 telescope is a fixed 3.4-power, 28-mm optical sight that has been designed to accurately engage targets out to 1,200 meters. The optical sight weighs 24 ounces (681 grams) and is extremely rugged for rough field conditions. The sight has an 8.2-mm diameter exit pupil, which provides excellent vision in low light levels; for example, dawn and dusk, and also for rapid target acquisition.

G-17. DESCRIPTION

The M145 straight telescope is a telescopic sight. The telescope magnifies targets by three and a half times or it appears to bring the shooter three and a half times closer to the target. The telescope shows more clearly the strike of the round and allows more accurate shooting. In low-light conditions, removal of the laser filter enhances target detection far better than that visible to the naked eye (Figure G-33). The lens cover protects the lens when the sight is being transport or stored. The lens cover should always be kept closed when the sight is not in use. The battery has an O-ring that keeps out moisture. With practice you may be able to keep both eyes open. With both eyes open, the gunner is more aware of the surroundings and feels less strain on his eyes. The M145 straight telescope must remain matched with the same weapon, attached at the same slot in the rail system, or if not, it must be rezeroed.

G-18. DATA

The following is the equipment's data.

|

Weight: |

24.0 ounces (681 grams) |

|

|

Length: |

7 inches (175mm) |

|

|

Battery Life: |

175 hours average (fresh battery) |

|

|

Sight is packed with a new battery. |

||

|

Optics: |

Antireflective coated lens system, (28mm) clear objective, x3.4 magnification. |

Figure G-33. M145 Telescope (MGO).

G-19. CONTROLS

The following is a brief description of the operation controls and its indicators.

a. Elevation Adjustment Dial. The elevation adjustment dial is used for zeroing the telescope to the weapon. The dial can only be rotated when the silver lock (1) is moved to the UP position. Turning the elevation adjustment dial (2) counterclockwise in the direction of the arrows one click moves the point of impact up 2.5 mm at 10 meters. Turning the elevation adjustment dial (2) clockwise (opposite direction to the arrow) one click moves the point of impact down 2.5 mm at 10 meters. Ensure that the silver lock (1) is moved down to prevent any further movement of the elevation adjustment dial (Figure G-34).

Figure G-34. Rotation of the elevation adjustment dial.

b. Windage Adjustment Screw. The windage adjustment screw is used when zeroing the weapon. Turning the windage adjustment screw (3) clockwise one click moves the point of impact left 2.5 mm at 10 meters. Turning the windage adjustment screw (3) counterclockwise, one click moves the point of impact right 2.5 mm at 10 meters (Figure G-35).

Figure G-35. Rotation of the windage adjustment screw.

G-20. BATTERY

This paragraph explains how to install and check the battery.

a. Remove battery cap (1) by turning it counterclockwise and holding the rotary reticle illumination switch (3) stationary.

CAUTION

|

b. Insert battery (2) with positive (+) end to cap (Figure G-36).

Figure G-36. Installing and checking batteries.

CAUTION

|

c. Reinstall the battery cap (1) by holding the rotary reticle illumination switch (3) stationary turning clockwise until snug. Tighten by hand only.

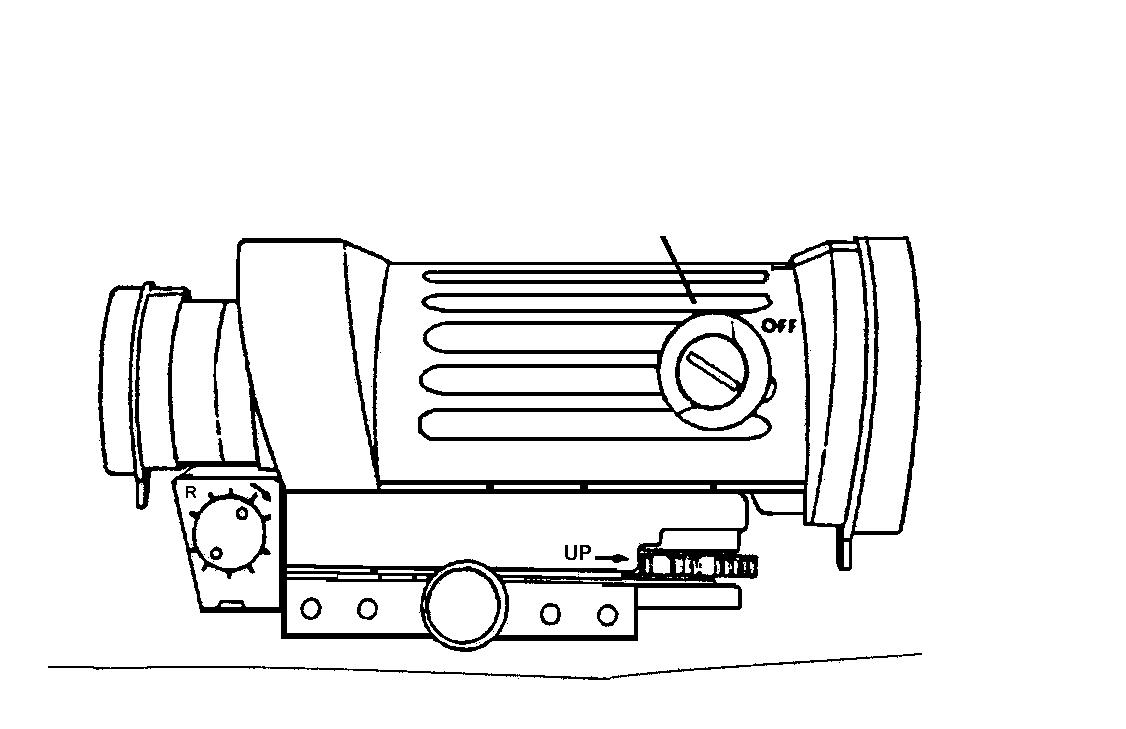

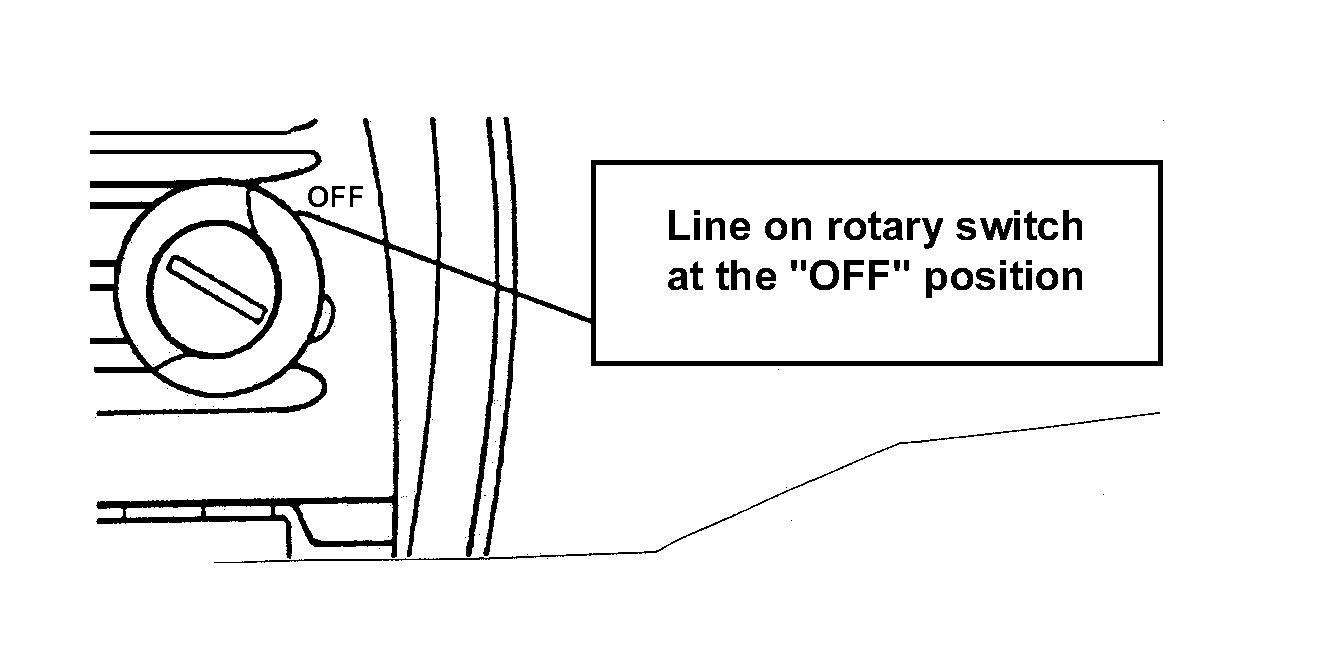

d. Open the rear lens cover (4). Turn the rotary reticle illumination switch (3) and look through rear lens. Verify that the reticle is illuminated. If not, replace the battery. When finished, turn the rotary switch to the OFF position, and then replace the rear lens cover (Figure G-37).

Figure G-37. Rotary reticle illumination switch.

G-21. INSTALLTION

The M145 straight telescope mounts directly to the mounting rail on the M249, and M240B machine guns. It is necessary that you adjust the position of the M145 telescope either backwards or forward on the rail in order to achieve the correct eye relief (distance of the eye from the back of the telescope). If the same sight is installed in the same position slot on the rail on the same weapon, rezeroing is not required.

CAUTION

|

a. Back off on the torque limiting knob just enough for the rail grabber to go over the rail. Do not force the torque limiting knob past its intended stop. Mount the M145 straight telescope firmly over the rail. Ensure that the mount is seated squarely over the rail. Tighten the torque limiting knob (clockwise) until it rotates with two clicks. Ensure that the mount is securely fastened before commencing eye relief adjustment. The sight is now mounted to the weapon about 3 inches (70 mm) in front of the firing eye (Figure G-38 [M249] and Figure G-39 [M240B]). Assume a comfortable firing position and achieve a good stockweld (at trigger pull length) with both eyes closed. Open the sighting eye and compare the view through the scope with the following figures:

Figure G-38. Mounting the MGO to the M249.

Figure G-39. Mounting the MGO the M240B.

(1) If the target scene fills the scope to provide the maximum field of view, the correct eye relief has been attained (Figure G-40). No further repositioning of the M145 on the mounting rail is required.

Figure G-40. Correct eye relief.

(2) If the target scene does not fill the sight's field of view, the optical sight must be repositioned on the rail either forwards or backwards (Figure G-41).

Figure G-41. Incorrect eye relief.

b. The optical sight must be repositioned for correct eye relief. Loosen the torque limiting knob and move the optical sight in the appropriate direction (forward or backward), which provides the full field of view.

c. Repeat a until the correct sight picture is obtained as shown in Figure G-41.

G-22. MOUNTING PROCEDURES (M60 ONLY)

Refer to Figures G-42a and G-42b when mounting MWTS on M60 machine gun.

a. Press on the end of the MWTS hinge pin latch (1) and remove the MWTS hinge pin latch and the MWTS hinge pin (2) from the M60 bracket (3).

b. Install the MWTS hinge pin (2) and the MWTS hinge pin latch (1) on the M60 machine gun (4).

c. Press on the right side end of the M60 hinge pin latch (5) with a pointed object and remove the M60 hinge pin latch.

d. Release the feed tray cover latch (6) and fully raise the feed tray cover (7).

e. Remove the M60 hinge pin (8). Keep the cover held in place.

f. Install the MWTS hinge pin (2) in right side of the hole (9).

g. Insert the MWTS hinge pin latch (1) through the left side of the MWTS hinge pin (2) until interlocked.

h. Lower the feed tray cover (7) and connect the feed tray cover latch (6).

i. Insert the M60 hinge pin (8) through the holes (10) of the bracket (3) and insert the M60 hinge pin latch (5) through the M60 hinge pin until interlocked.

j. Close the objective lens cover.

k. Push in the cam release and slide the rail back until the rail locks in place.

l. Open the M60 machine gun feed tray cover.

Figure G-42a. Mounting the MGO to the M60 machine gun.

m. Install the bracket (3) on the M60 machine gun (4). Fold the rear sight (11) forward. Place the pins (12) of the bracket (3) in the cups (13) of the MWTS hinge pin (2) and the MWTS hinge pin latch (1) and tighten the nut (14) by hand. Tighten the locking nut (15) by hand. Place the groove (16) of the two clamping bars (17) on the edge of the feed tray cover (4) and tighten the two thumbwheels (18).

n. Install the MGO on the rail. Loosen the clamping knob on the mount. Select the slot on the rail for mounting. Any slot may be used as long as the mount does not hang over edge of rail. Place the bar of the mount in the slot of the rail and tighten the knob on the mount by hand until two clicks are heard.

Figure G-42b. Mounting the MGO to the M60 (continued).

G-23. ZEROE PROCEDURES

The following paragraphs explain the different ways to zero the M145 straight telescope on the M240B, M60, and M249 machine guns.

a. Zeroing to Weapon. Zeroing the M145 straight telescope aligns the sight to the barrel of the machine gun so that the point of aim equals the point of impact. Adjustment of the M145 straight telescope is centered at the factory.

(1) Open the front (1) and the rear (2) lens covers.

(2) Turn each cover inside out to stow the lens covers while the sight is being used (Figure G-43).

Figure G-43. Stowing the lens covers.

b. 10-Meter Zeroing, Setting to Mechanical Zero.

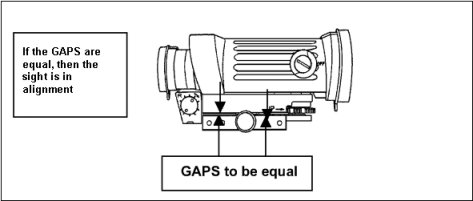

(1) Adjust the straight telescope so that the weapon's barrel and the optical sighting axis are in alignment. The sighting axis is about 2 to 3 inches above the machine gun barrel, and therefore the strike of the bullet at a 10-meter range is also about 2 to 3 inches low without further zeroing adjustment (Figure G-44). To bring the strike of the bullet up, lift the silver lock and rotate the elevation adjustment dial counterclockwise (to the right) about one full turn.

Figure G-44. GAPS to be equal.

(2) Adjust the windage dial to center the markings on the front of the sight. This adjustment brings the bullet's point of impact to the middle of the point of aim (Figure G-45). Each click of zeroing adjustments makes a 2.5 mm movement of the point of impact at 10 meters.

Figure G-45. Centering the markings.

(3) To move the point of impact to the right, turn the windage adjustment screw (2) counterclockwise with the arrow marked on the dial.

(4) To move the point of impact to the left, turn the windage adjustment screw (2) clockwise opposite to the arrow.

(5) To move point of impact up, turn the elevation adjustment screw (1) counterclockwise (right) with the direction of the arrow marked and "UP."

(6) To move the point of impact down, turn the elevation adjustment screw (1) clockwise (left) opposite to the arrow (Figure G-46).

Figure G-46. Adjusting point of impact.

c. 10-Meter Range Zeroing. In the zeroing process, groups of three-single shot rounds are fired at a target. After each three rounds, the center of the group has to be determined.

(1) Look through the telescope and align the reticle's 10-meter zeroing mark on the center base of the aiming points on the basic machine gun marksmanship target (Figure G-47).

Figure G-47. 10-meter reticle aiming point.

(2) Fire three-single rounds loaded individually without making any sight adjustments.

(3) The three-round shot group should be within a 4-cm circle to establish the center of the shot group in relation to the center base of the aiming paster.

(4) Measure the amount of movement that is required left or right (windage) and either up or down (elevation) to move the three-round shot group onto the center of the aiming paster.

(5) Upon completion, return to the firing line to make corrections to the weapon and refire a three-round shot group to confirm zero (Figure G-48).

Figure G-48. Three-round shot group with adjustments.

(6) Repeat the above steps until the strike of the round is coincident with the center of the target. Close the silver lock down to prevent any further movement of the elevation zeroing adjustment dial.

d. Field Zeroing at 500-Meter Range. Look through the telescope and align the reticle's 500-meter mark on the center of mass of the double "E" silhouette target (Figure G-49):

Figure G-49. 500-meter reticle aiming point.

(1) M240B, M60, and M249 machine guns: Fire a 5- to 7-round burst.

(2) Observe the impact of the rounds.

(3) Determine the direction of impact to be moved (up or down, left or right).

(4) Estimate or measure the amount of movement required to move the strike of the round to the center of the target (at 500 meters; 5 inches equals one click of adjustment in both windage and elevations). Repeat these steps until the strike of the round coincides with the center of the target.

| NOTE: | Close the silver lock down to prevent any further movement of the elevation zeroing adjustment dial. The M145 straight telescope is now zeroed and ready for operational shooting. |

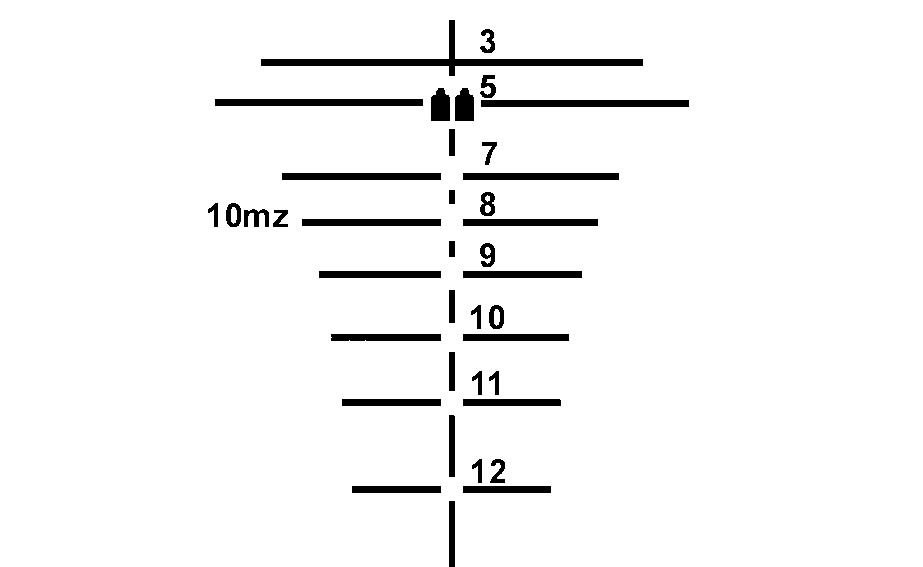

e. Using Reticle to Estimate Range. The vertical gap in the stadia lines is for estimating ranges. The height of gaps in the stadia lines represents a 60-inch high target at the range noted; for example, 5, 7, 8, 9, 10, 11, or 1,200 meters (Figure G-50).

Figure G-50. Reticle stadia lines.

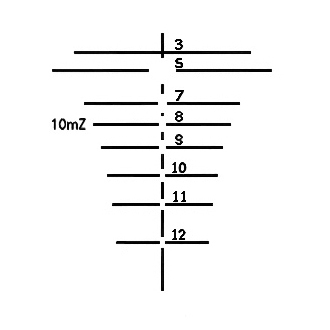

f. Illuminating the Reticle. For low light operations, the reticle can be illuminated to show the 300-, 500-, 700-, and 800-meter aiming marks (Figure G-51). The sight is equipped with variable intensity LED illumination of the reticle. It has 10 positions: one OFF position and 9 positions for different reticle intensity settings.

Figure G-51. Illuminated reticle.

(1) To make reticle illumination adjustments, turn the rotary switch (1) clockwise. The intensity of the illumination increases the further the switch is turned (Figure G-52).

Figure G-52. Illuminated reticle adjustments.

(2) Turn the rotary switch to the OFF position when the telescope is being used during normal daylight or when illumination is not required (Figure G-53). Ensure the reticle illumination switch is turned to the OFF position when not required.

Figure G-53. OFF switch.

G-21. MOUNTING AND ZEROING THE AN/PVS-4

Zeroing aligns the AN/PVS-4 to the M249. The sight may be zeroed during daylight or darkness. (See TM 11-5855-213-10.) If done during daylight, the daylight cover must be used. To obtain a precise zero, it is best done at 300 meters and at night. Once an AN/PVS-4 has been zeroed on an M249 machine gun, any soldier who knows how to use the reticle should fire the weapon effectively. However, there may be some changes in zero when the objective focus is adjusted to engage targets at various ranges and when the diopter focus is adjusted for the vision of different firers. A metal target is excellent for zeroing purposes, because the strike of the round can be easily observed with an AN/PVS-4. The procedures to zero are as follows.

a. Mounting the Bracket and Device. Before zeroing and qualifying with the AN/PVS-4, the gunner must mount the bracket and sight onto his weapon.

CAUTION

|

(1) Place the mounting bracket on top of the feed cover mechanism assembly so that the two forked ends are secured around the headless pins.

(2) Remove the screw cover behind the rear sight assembly, and screw the bracket knob in until it is tight.

(3) Position the AN/PVS-4 on top of the bracket so that the mount of the AN/PVS-4 is aligned with the mounting knob of the bracket.

(4) Turn the mounting knob clockwise until the AN/PVS-4 is tight (Figure G-54).

Figure G-54. Mounting the AN/PVS-4 to the M249 light machine gun.

b. Seating the Device. Once the device is mounted, the gunner fires a 3-round burst to seat the device, checks and tightens the mounting knob, and then fires another 3-round burst. He checks the device to ensure it is settled and securely fastened and tightens the mounting knob if necessary. He does not fire at the boresight target during this procedure.

c. Centering the Reticle in the Field of View. The gunner turns the device on and centers the reticle pattern in the field of view by using the azimuth and elevation actuators. To be accurate, he does this by rotating the elevation and azimuth actuators from one side to the other and from top to bottom, while counting the number of clicks. The elevation actuator has the down direction marked DN with an arrow. This moves strike of the round. The azimuth actuator has the right direction marked with RT with an arrow. This also moves the strike of the round. He divides the number of clicks for each by two and moves the elevation and azimuth actuators that number of clicks. This manually centers the reticle in the field of view horizontally and vertically. This enables the gunner to reach an accurate boresight between the point of aim (reticle) and the center of the bore (Figure G-55).

Figure G-55. Centered reticle pattern.

d. Confirming the Boresight. To do this, the gunner centers and affixes a 25-meter (M16A2) zero target to the back of a basic machine gun paster target. This provides a large, clear surface for identifying the strike of the round. Then, he emplaces the target 10 meters from the firing position. The gunner places the reticle aiming point on the 25-meter zero target aiming point (Figure G-56) and fires a single round. If the round impacts anywhere near the aiming point, he fires two more rounds to establish his group.

Figure G-56. Reticle aiming point, target aiming point and shot group.

e. 25-Meter Zeroing. After a boresight has been established, the gunner moves back to a 25-meter firing position. He affixes another 25-meter zero target to the back of a 10-meter machine gun target and fires three rounds.

(1) Locate and triangulate the center of the shot group. From the center of the shot group, adjust the reticle to move the center of the shot group to a point 8 cm below and 2 cm right of the target aiming point (Figure G-57). This location on the 25-meter zero target is 9 squares below (8 cm divided by .9) and 2 squares right (2 cm divided by .9) of the target aiming point. Make the adjustment using the AN/PVS-4 azimuth and elevation adjustment actuators. Each square on the 25-meter zero target is .9 cm. Each click of the actuators moves the strike of the round .25 cm (or .1 inch) at 10-meters. Therefore, 4 clicks on either the elevation or azimuth actuator moves the strike of the round one square.

(2) After making the adjustments, assume a stable position, place the reticle aiming point on the target aiming point, and fire three more single rounds. Repeat the process until the rounds impact within the desired location (9 squares below and 2 squares right).

(3) If you miss the 25-meter zero target with the first round but strike the 10-meter machine gun paster target, make a large adjustment with the elevation and azimuth actuators. Continue this process with three-round groups and adjustments until the rounds strike the desired location.

(4) Do not record the zero because when the AN/PVS-4 is dismounted and remounted on the same M249, some changes may occur. It is best to zero each time.

(5) Once the AN/PVS-4 is mounted and boresighted, fire a 3-round burst at the center base of the target and note the strike of the rounds. While maintaining the reticle aiming point on the target, move the reticle aiming point to the strike of the rounds by manipulating the elevation and azimuth actuators.

(6) Acquire a good sight picture on the target with the reticle aiming point once again and fire another 3-round burst. Note the strike of the rounds and repeat the process until the rounds impact on target.

f. Mounting the AN/PVS-4 on the M60. Before zeroing and qualifying with the AN/PVS-4, the gunner must mount the bracket and sight onto his weapon. The M60 machine gun requires a mounting bracket.

CAUTION

|

(1) The gunner removes the M60 hinge pin latch and hinge pin from the over assembly by pressing on the latch (open end of pin) with an empty cartridge case, and separates the latch and pin. He places the pin and latch in the aiming guides on the left side of the mounting bracket and presses together.

(2) The gunner positions the mounting bracket assembly on top of the machine gun cover so that the holes in the front of the bracket align with the cover assembly pin holes.

(3) The gunner inserts the longer hinge pin supplied with the bracket through the bracket-and-cover assembly, and secures by inserting the hinge pin latch.

(4) The gunner loosens the wing nuts on both leg clamps and positions the clamps under the cover assembly. He secures the mounting bracket by tightening the wing nuts firmly (Figure G-57).

(5) The split washer is placed next to the wing nut and the flat washer is placed next to the bracket.

Figure G-57. Installation of mounting bracket.

(5) The gunner installs the sight on the M60 mounting bracket assembly by positioning it in the groove on top of the bracket so that the scribe line on the bracket is aligned with the scribe line on the sight mounting adapter. He tightens the lever screw assembly to secure the sight to the bracket. He uses an empty cartridge case placed over the lever arm to increase leverage as the screw is tightened. (See Figure G-58.)

Figure G-58. Mounting the AN/PVS-4.

g. Mounting the AN/PVS-4 on the M240B.

Before zeroing and qualifying with the AN/PVS-4, the gunner must mount the sight onto his weapon. The M240B machine gun has a rail mount already attached to the cover assembly (Figure G-59). The gunner installs the sight on the M240B rail mount by loosen the mounting knob located on the left side. Positioning it in a slot on the rail mount. Any slot may be used as long as the mount does not hang over the edge of the rail. By placing the bar of the mount in a slot on the rail and hand tighten knob on mount until clicking noise is heard (2 clicks). As long as the gunner places the sight in the same slot after zeroing the sight will retain its zero to a degree. (See Figure G-60.)

Figure G-59. Rail mount on the M240B.

Figure G-60. Mounting the AN/PVS-4.

h. Zeroing the AN/PVS-4 to the M60/M240B. Zeroing aligns the AN/PVS-4 to the machine gun. The sight may be zeroed during daylight or darkness. (AN/PVS-4 TM 11-5855-213-10) When zeroing during daylight, the daylight cover must be used. To obtain a precise zero, it is best done at 300 meters and at night. Once the AN/PVS-4 is zeroed on the machine gun, any soldier who knows how to use the reticle should fire the weapon effectively. However, there may be some changes in zero when the objective focus is adjusted to engage targets at various ranges and when the diopter focus is adjusted for the vision of different firers. A metal target is excellent for zeroing purposes, because the strike of the round can be easily observed with an AN/PVS-4. The procedures to zero are as follows:

(1) Seating the Device. Once the device is mounted, the gunner fires a seven-round burst to seat the device, checks and tightens the mounting knob, and then fires another three-round burst. He checks the device to ensure it is settled and securely fastened and tightens the mounting knob if necessary. He does not fire at the boresight target during this procedure.

(2) Centering the Reticle in the Field of View of the AN/PVS-4. The gunner turns the device on and centers the reticle pattern in the field of view by using the azimuth and elevation actuators. To be accurate, he does this by rotating the elevation and azimuth actuators from one side to the other and from top to bottom, while counting the number of clicks. (The elevation actuator has the down direction marked DN with an arrow. This moves strike of the round. The azimuth actuator has the right direction marked with RT with an arrow. This also moves the strike of the round.) He divides the number of clicks for each by two and moves the elevation and azimuth actuators that number of clicks. This manually centers the reticle in the field of view horizontally and vertically. This enables the gunner to reach an accurate boresight between the point of aim (reticle) and the center of the bore (Figure G-61).

Figure G-61. Centered reticle pattern.

(3) Confirming the Boresight. To confirm the boresight, the gunner centers and affixes a 25-meter (M16A2) zero target to the back of a basic machine gun paster target. This provides a large, clear surface for identifying the strike of the round. Then, he emplaces the target 10-meters from the firing position. The gunner places the reticle aiming point on the 25-meter zero target aiming point (Figure G-62) and fires a single round. If the round impacts anywhere near the aiming point, he fires two more rounds to establish his group.

Figure G-62. Reticle aiming point, target aiming point and shot group.

(4) 25-Meter Zeroing AN/PVS-4. After a boresight has been established, the gunner moves back to a 25-meter firing position. He affixes another 25-meter zero target to the back of a 10-meter machine gun target and fires three rounds.

(a) AN/PVS-4 (M60 and M240B) The gunner locates and triangulates the center of the shot group. From the center of the shot group, he adjusts the reticle to move the center of the shot group to a point 8 cm below and 2 cm right of the target aiming point. This location on the 25-meter zero target is 9 squares below (8 cm divided by .9) and 2 squares right (2 cm divided by .9) of the target aiming point. He makes the adjustment using the AN/PVS-4 azimuth and elevation adjustment actuators. Each square on the 25-meter zero target is .9 cm. Each click of the actuators moves the strike of the round .25 cm (or .1 inch) at 10 meters. Therefore, 4 clicks on either the elevation or azimuth actuator moves the strike of the round one square.

(b) After making the adjustments, the gunner assumes a stable position, places the reticle aiming point on the target aiming point, and fires three more single rounds. He repeats the process until the rounds impact within the desired location (9 squares below and 2 squares right).

(c) If he misses the 25-meter zero target with the first round but strikes the 10-meter machine gun paster target, he makes a large adjustment with the elevation and azimuth actuators. He continues this process with three-round groups and adjustments until the rounds strike the desired location.

(d) He does not record the zero with the old style bracket because when the AN/PVS-4 is dismounted and remounted on the same M60, some changes may occur. It is best to zero each time. The zero is recorded with the new rail bracket because when the AN/PVS-4 is dismounted and remounted on the same machine gun, and as long as the gunner places a mark on the rail slot the sight will have some changes. But the gunner does not need to re-zero his sight to the machine gun.

(e) Once the AN/PVS-4 is mounted and boresighted, the gunner fires a three-round burst at the center base of the target and notes the strike of the rounds. While maintaining the reticle aiming point on the target, he moves the reticle aiming point to the strike of the rounds by manipulating the elevation and azimuth actuators.

(f) The gunner acquires a good sight picture on the target with the reticle aiming point once again and fires another three-round burst. He notes the strike of the rounds and repeats the process until the rounds impact on target.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|