Kuaizhou KZ-21 / KZ-31

With the ultra-large diameter solid rocket motor with a large-thrust, the carrying capacity of Kuaizhou series will be increased from 1 ton to 20 tons and the cost for launching a rocket will be further lowered to $5,000 per kilogram, highly competitive compared with the ruling price range of $20,000-30,000 per kg in the present world market. The coming out of the ultra-large diameter solid rocket motor is a significant milestone in China's commercial space flight development.

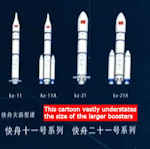

Specifications for the larger rockets are sparse. One published artwork suggests an overall length of about 25 meters for the KZ-21, only slightly less than the 19.5 meter KZ-1. This is clearly too small for the claimed payload. Another artist's concept suggests an an overall length of about 45 meters for the KZ-21, which is probably closer to the mark. With a diameter of 4 meters, the KZ-21 would have a cross section of 12.5 square meters, in contrast to the 1.5 square meter cross section of the 1.4 meter diameter KZ-1, or the the 3.8 square meter cross section of the 2.2 meter diameter KZ-11. With a 2.2 meter diameter, the KZ-11 appears to be about 22.5 meters long, for a total volume of roughly 85 cubic meters. With a LEO payload of 30,000 kg, the KZ-21 has roughly 20 times the payload of the 1,500 kg KZ-11. In very round numbers, this would imply a total volume of 1,700 cubic meters for the KZ-21, which with a diameter of 4 meters [and a cross section of 12.5 square meters] would imply a length in excess of 125 meters, an implausibly large number.

Specifications for the larger rockets are sparse. One published artwork suggests an overall length of about 25 meters for the KZ-21, only slightly less than the 19.5 meter KZ-1. This is clearly too small for the claimed payload. Another artist's concept suggests an an overall length of about 45 meters for the KZ-21, which is probably closer to the mark. With a diameter of 4 meters, the KZ-21 would have a cross section of 12.5 square meters, in contrast to the 1.5 square meter cross section of the 1.4 meter diameter KZ-1, or the the 3.8 square meter cross section of the 2.2 meter diameter KZ-11. With a 2.2 meter diameter, the KZ-11 appears to be about 22.5 meters long, for a total volume of roughly 85 cubic meters. With a LEO payload of 30,000 kg, the KZ-21 has roughly 20 times the payload of the 1,500 kg KZ-11. In very round numbers, this would imply a total volume of 1,700 cubic meters for the KZ-21, which with a diameter of 4 meters [and a cross section of 12.5 square meters] would imply a length in excess of 125 meters, an implausibly large number.

One published artist's concept depicts KZ-11A and KZ-21A configurations using strap-on boosters smaller than the core vehicle [presumably the KZ-11A uses KZ-1 motors as strapons, and the KZ-21A uses the KZ-11 as strapons. The claimed KZ-21 payload might be achieved by a pair of 4 meter strap-on motors [to achieve an effective aggregate motor length of 125 meters, while the claimed KZ-31 performace might be achieved with a cluster of four or six 4 meter strapons. These are extremely rough order of magnitude calculations, but they clearly demonstrate a mismatch between claimed performance and depicted configurations.

Solid rockets are of interest to the space program because they are commonly used as boosters that provide the additional thrust needed for the space launch vehicle to escape the gravitational pull of the Earth. Larger, more advanced solid rockets allow for space launch vehicles with larger payload capacities, enabling humanity to reach new depths of space.

In the United States, the 260-inch [6.6 meter] Solid Rocket Motor Demonstration Program, which was completed in 1967, established the feasibility of large solid rocket motors. The experimental motor, more than 22 feet in diameter and 80 feet long, is part of the large solid motor technology program conducted by the National Aeronautics and Space Admlnistration. The results of the three 260 inch motor tests demonstrated its inherent simplicity, low cost potential and reliability. Since the end of this 260 inch Solid Rocket Motor Demonstration Program, NASA has supported, through the Lewis Research Center, additional advanced technology for large solid rocket motors.

The US Space Shuttle Solid Rocket Motor was the largest solid propellant motor ever developed for space flight and the first built to be used on a manned craft. The huge motor is composed of a segmented motor case loaded with solid propellants, an ignition system, a movable nozzle and the necessary instrumentation and integration hardware. Each solid rocket motor contained more than 450,000 kg (1,000,000 lb.) of propellant. The Advanced Solid Rocket Motor (ASRM) case design aimed at achieving a safer and more reliable solid rocket motor for the Space Shuttle system is considered. The ASRM case has a 150.0 inch diameter [3.81 meters], three equal length segment, and 9Ni-4CO-0.3C steel alloy.

NASA’s Space Launch System (SLS) solid rocket booster is the largest, most powerful solid propellant booster ever built for flight. The major physical difference between the shuttle and SLS boosters is the addition of a fifth propellant segment to the four-segment shuttle booster, allowing NASA’s new launch-er to lift more weight than the shuttle.

China will begin testing the world’s largest solid-propellant rocket engine in February, according to a senior space scientist interviewed on 24 December 2017. Liang Jiqiu, chief designer of Kuaizhou rockets at China Aerospace Science and Industry Corp, the nation’s largest missile-maker, described the engine as having a diameter of over 4 meters and a liftoff thrust of more than 1,000 metric tons. Until now, the largest solid-propellant rocket in the world — developed by Orbital ATK Inc in the United States — had a diameter of 3.7 meters, he said.

China will begin testing the world’s largest solid-propellant rocket engine in February, according to a senior space scientist interviewed on 24 December 2017. Liang Jiqiu, chief designer of Kuaizhou rockets at China Aerospace Science and Industry Corp, the nation’s largest missile-maker, described the engine as having a diameter of over 4 meters and a liftoff thrust of more than 1,000 metric tons. Until now, the largest solid-propellant rocket in the world — developed by Orbital ATK Inc in the United States — had a diameter of 3.7 meters, he said.

Engineers were required to overcome a host of technical obstacles because China had never developed such a large and sophisticated solid-propellant rocket and there were some gaps in their knowledge of structure, materials and mechanics, Liang said. Tests of components have now been completed and engineers are assembling an engine for ignition tests, he said.

The engine will be used with Kuaizhou 21 and Kuaizhou 31 rockets, both new-generation models under development at CASIC. Kuaizhou 21 will be capable of sending a 20-ton spacecraft to low Earth orbit while Kuaizhou 31 will be able to transport a 70-ton payload, he said. CASIC began to develop the Kuaizhou series in 2009 as a low-cost, quick-response product for the commercial space market. It had launched three: two Kuaizhou 1s and one Kuaizhou 1A.

In 2018, with the support of China's civil aerospace project, the Fourth Academy of Aerospace Engineering launched the development of a larger-scale 3.2 meter 3-segment technology to verify the solid engine. In more than two years, the R&D team successfully overcame, verified, and applied a number of major key technologies, solved more than 10 technical difficulties, formed 5 sets of new design methods, 3 sets of new processes, and compiled 6 design specifications. Completely independent intellectual property rights provide support for the research of large-scale multi-segment engine assembly and general test technology. The success of the engine test has once again set a number of records for China's large-scale segmented solid engine.

According to Wang Jianru, chief designer of high-thrust solid engine of the Fourth Academy of Aerospace Engineering, in the future, the 3.2-meter engine can be used in the solid booster of large and heavy launch vehicles. The single-stage scale would be expanded, and the engine thrust would be greatly increased, which can meet the needs of Chinese space equipment, and the different development needs of manned moon landing and deep space exploration. Ren Quanbin, secretary of the Party Committee of the Fourth Academy of Aerospace Engineering, said that the successful development of the engine has further improved China's independent innovation capability and level of large-scale solid engines, and at the same time opened the prelude to solid engines entering the field of launch vehicle bundling and boosting power.

In addition, the success of this test further verified the design scheme of China's large-scale segmented solid rocket engine and its key technologies, improved the technical level of China's large-scale solid rocket engine, and promoted the enhancement and expansion of China's aerospace new-generation launch vehicle capabilities. It was reported that the Fourth Aerospace Academy was based on the development needs of China's launch vehicle type spectrum, and was conducting research on a 500-ton high-thrust monolithic solid engine with comprehensive performance reaching the world's advanced level.

On 30 December 2020, China’s self-developed civil aerospace industry’s first large-scale solid rocket motor with three 3.2m segments completed its first test vehicle in Xi’an. This was the segmented solid with the largest thrust so far in China. The solid engine tested this time had a maximum thrust of 260 tons and adopted a three-segment design. Following China's rapid development in space technology, the new solid rocket booster can be applied to large and heavy rockets and meet a varied range of needs across aerospace equipment, manned moon landing and deep space exploration

On 19 October 2021 Chinese space engineers conducted the first ignition test of the most powerful solid-propellant rocket engine in the world, which will be used on new-generation rockets, according to the Academy of Aerospace Solid Propulsion Technology in Xi'an, Shaanxi province. The academy, a subsidiary of State-owned space giant China Aerospace Science and Technology Corp, announced that the test had been successful. The engine has a diameter of 3.5 meters, 150 metric tons of solid propellants and a thrust power of 500 tons, making it the world's most powerful and fuel-efficient integrated solid-propellant rocket engine, the academy said in a statement, noting that the test took place at an engine testing facility in Xi'an. Wang Jianru, chief designer of the engine, said that it integrates a number of advanced technologies and high-performance composite materials and has world-class capability. "The test's success means that we have achieved substantial progress in improving the capability of our solid-propellant carrier rockets. It also laid a key foundation for our research and development for a 1,000-ton-thrust engine," he said, noting that the new engines are necessary for China to build super-heavy rockets.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|