VM-A Atomic Reactor, Submarine

In 1952, the United States began construction of the world's first nuclear-powered submarine. Of course, the USSR could not remain a passive observer, and Soviet nuclear scientists and shipbuilders began to develop their own nuclear submarine (NPS), which received the top-secret name "Object 627." As a result of the creation of the nuclear submarine of project 627, the USSR became the second power in the world with a nuclear submarine fleet. Submarines of project 627 had outstanding characteristics for their time, but also had significant shortcomings that were corrected in the next-generation nuclear submarines.

In the USSR, work on the creation of a submarine with a nuclear propulsion system began in August 1952. The impetus for them was a letter to the government of atomic "patriarchs" - I.V. Kurchatova A.P. Alexandrova and N.A. Dollezhal - on the need to create a domestic nuclear submarine in order to eliminate a significant lag behind the Americans in this area. The most important and complex part of this project was the development of a nuclear power plant, for which it was necessary to solve a number of complex engineering problems.

The entire project was placed under the responsibility of the First General Directorate. Academician A.P. Alexandrov (LIPAN), chief designer for energy - Academician N.A. Dollezhal (NIIkhimmash / NII-8). Responsible for the development of the ship became V.N. Peregudov (Leningrad SKB-143 of the Ministry of Shipbuilding).

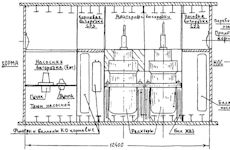

During the pre-design studies, a variant of the nuclear power plant was chosen consisting of two reactors installed along the boat axis, the main dimensions of the reactor were determined (a compartment with a length of 12 m and a diameter of 6.8 m was allocated for them), its type (two options - with a beryllium moderator and water-water) and power (70 MW heat.). Subsequently, the beryllium reactor had to be abandoned due to the complexity of the design, the need for a large loading of uranium and the toxicity of beryllium. At first, LIPAN and NIKIET specialists focused on the idea of a channel water-graphite reactor similar in design to the first nuclear power plant in the world being built at that time, but then preference was given to a shell-type reactor (WWR) with pressurized water, as a more compact and with less loading of enriched uranium.

The reactor, which received the BM-A index, had the following design features: the forged casing of thick-walled high-strength carbon steel was made with an insert bottom and an insert jacket, pipes were welded to the jacket. The flat reactor lid was sealed with a pressure flange. For the new reactor, an original design of the core was adopted, which was formed from individually cooled fuel assemblies with their placement in a screen assembly, as in a removable unit. This made it possible to carry out both per-channel replacement of nuclear fuel and its complete emergency unloading.

In March 1954, the Ministry of Environment approved the technical design of the reactor, and the designer began to develop working drawings of the equipment. During the development, a whole series of questions arose on optimizing the thermal scheme of a nuclear reactor (NR) and its parameters; a scheme for regulating neutron processes in nuclear weapons; methods of neutron-physical calculation of water-water NR; the problems of deep burning of nuclear fuel and the accumulation of 235U fission fragments, the creation of a thermotechnical model of a nuclear installation; development of a scheme for automatic control of a nuclear installation.

To solve them in Obninsk at the Physics and Power Engineering Institute, a ground-based full-scale stand 27 / VM with a steam turbine plant began to be built. It was supposed to check the correctness of the circuit, layout and design decisions of the reactor installation, to identify equipment deficiencies for their timely elimination. For this purpose, at the plant No. 92 (Gorky), three sets of the reactor installation were made simultaneously: one for stand 27 / VM and two for the future nuclear submarine.

In parallel with the development of nuclear submarines and their power plants, a nuclear power plant ground stand is being designed (its index is 27VM), which reproduces the reactor and turbine compartments of the boat with equipment and starboard installation systems. The tasks of the stand are to check the operability of the installation and its elements, the convenience of maintenance and repairs, the living conditions in the energy compartments, as well as the training of submarine crews. In July 1955, the main construction work on the building and facilities of the stand was completed, the production of basic equipment was completed. The manufacturer of turbine units for the stand, and then for the nuclear submarines, was the Kirov Plant, and most of the equipment of the bench and ship reactor facilities — from the reactors themselves to large pipelines — was Plant No. 92. Their working drawings were developed by the staff of I.I. Afrikantov factory OKB, together with a large group of designers of NII-8, seconded to the bureau in the summer of 1954, drawings of the mechanisms of the control and control system, with S.M. Frankstein (OKB-12).

Supervised the development of a working draft from the Design Bureau of the plant - Yu.N. Koshkin and from NII-8 - P.A. Delens. Technological development of the drawings was carried out by specialists of the relevant services of the plant, after which they immediately entered the workshops. At the same time, the necessary stands and equipment for testing equipment and its components were developed and manufactured. after which they immediately entered the workshops. At the same time, the necessary stands and equipment for testing equipment and its components were developed and manufactured. after which they immediately entered the workshops. At the same time, the necessary stands and equipment for testing equipment and its components were developed and manufactured.

The supervisor of studies A.P. Alexandrov and chief designer N.A. Dolezhal, which allowed designers and manufacturers to quickly solve the most complex issues that arose. The progress of detailed design and manufacturing was controlled by senior employees of the Ministry of Environment and the Ministry of Defense, whose system included the plant.

In the fall of 1954, sailors of the first crew of the nuclear submarine under construction began to arrive in Obninsk. They underwent an internship at the world's first nuclear power plant (AM reactor), which was recently commissioned, and after obtaining permission to operate a nuclear reactor, they controlled the installation of the test bench equipment.

By this time, at the plant number 12 in Elektrostal 3 sets of fuel rods for the reactor core were manufactured. Initially, fuel rods were made using two alternative technologies: with a powder-filled fuel composition with further impregnation with lead-bismuth eutectic (developed by NII-9) and with a tablet fuel composition (developed by LIPAN). Subsequently, more advanced fuel rods of the NII-9 design — a rod and ring type with a fuel composition based on an uranium-silicon-aluminum alloy — were used in the VM-A reactors. Uranium enriched 21% in uranium-235 was used in fuel rods. The fuel assembly consisted of two groups of fuel rods - central (9 pcs.) And peripheral (14 pcs.) With a separation pipe between them.

On March 8, 1956, a physical start-up of the active zone of the first ship's reactor in the USSR was successfully carried out at the mounted nuclear power plant of stand 27 / VM (the sailors trained and passed the exam were the stand operators). At the beginning of April 1956, the first working steam was received at the stand and the turbo-generator mode was reached. During the first period of operation of the 27VM stand, physical studies of the reactor core were carried out, including at operating pressures and coolant temperatures, which confirmed the design neutron-physical characteristics of the zone and allowed to expand work on their further improvement.

The work of the stand was accompanied by a large number of emergency stops due to coolant leaks and equipment failure. At the end of 1956, another accident occurred, which ended with the destruction of part of the active zone and the ingress of a highly active coolant into the working room, which temporarily excluded the possibility of operating the stand. Nevertheless, the experience gained made it possible to make significant changes in the design of the reactor regarding biological protection, the core, actuators, etc.

At this time, the construction of the submarine itself was already in full swing, the laying of which on the slipway of plant No. 402 in Severodvinsk took place on September 24, 1955. The pace of construction of the nuclear submarine was practically not affected by very significant adjustments to its technical design and working documentation, made according to the comments of the Navy. Specialists of SKB-143 managed to carry out all changes to the drawings during construction, while maintaining most of the existing backlog. The construction process was complicated by another: difficulties affected the supply of equipment completing the ship from numerous (about 80) plants, caused by a lack of experience in manufacturing products new to our industry with increased quality requirements, and the development of non-traditional structural materials and technologies. And for the plant number 402 itself, the atomic boat was the first, which was manifested, for example, in the installation, welding, and control of branched high-pressure pipelines in the reactor compartment, requiring special attention. In these circumstances, the experience of the Ministry of Mediation and Medvedev organizations came in handy, behind which there was already the construction of a ground 27VM stand.

In 1956, two sets of equipment for reactor plants "VM-A" were delivered to Plant No. 402 as part of reactor vessels without active zones, covers, actuators for reactor protection control systems, pipelines, etc. On September 29, 1956, their installation began. Particular attention was paid to the quality of the welds, the leak test of which was carried out by several methods.

The VM-A reactor installation consisted of two main circulation circuits in which water was used as a heat carrier, as well as auxiliary and maintenance systems. The circulation of water along the primary circuit is ensured by sealless hermetic electric pumps - main and auxiliary. The third circulation circuit with fresh water was used to remove heat from the metal structures of the tanks for iron-water protection of the reactor, pump bearings, and drive mechanisms. Heat was removed from the third circuit by a fourth circulating circuit with sea water. To ensure an acceptable level of radiation in the boat’s premises, special biosecurity structures in the form of blocks of absorbing materials were installed in the reactor compartment, and lead was used in the end bulkheads of the reactor compartment and deck decks.

In May 1957, the work of the modernized stand 27 / VM resumed. The main conclusion made by the supervisor and chief designer based on the experience of its operation was as follows: the reactor unit "VM-A" in its basic design, composition and layout of equipment, controls and protection is designed correctly.

On August 9, 1957, the nuclear submarine was withdrawn from workshop No. 42 and launched into the water for its subsequent completion afloat. In early September, loading of the active zones into the reactor began: in the bow reactor - the zone with ring fuel rods, in the feed reactor - with the rod fuel rods. The loading of channels and fuel elements into the cells of the screen assemblies of the reactors was carried out according to cartograms with constant monitoring of the physical parameters of the active zones. Then began filling the reactors with high purity water.

September 13, 1957 under the leadership of A.P. Alexandrova and LIPAN employees began the procedure of physical start-up of both reactors with access to a minimally controlled power level. After eliminating a number of problems by mid-April 1958, the nuclear power plant of the nuclear submarine was ready for putting into operation.

On April 19, 1958, first at one, and then (May 18) and at another reactor, 18% of the design capacity was achieved. The successful operation of the nuclear power plant for several weeks gave rise to the transfer of the boat to complex mooring trials (KSH). Integrated mooring trials are the most important and crucial stage of any ship under construction.

On May 19, 1958, the boat (she was assigned tactical number K-3, from the end of 1962 she bore the name "Lenin Komsomol") was presented to the KSH, which began on the same day. The tests were carried out around the clock and ended on June 5, 1958. The maximum power at the reactor achieved during the tests was 60% of the nominal. The acceptance interdepartmental commission in the act evaluated the quality of installation and ease of maintenance of equipment, living conditions in the submarine compartments and other indicators as "satisfactory". By the signed act, the nuclear power plant and the VM-A reactors were allowed to conduct state sea trials of the boat, on which the submarine was presented on July 3, 1958. On July 4, under the supervision of a group of LIPAN employees, the nuclear power plant began to be brought to power, under A.P. Alexandrov, who led the process.

The positive results of these works continued until June 5, 1958, to conduct integrated mooring tests of the power plant under the leadership of the interagency commission. Its power was limited to 60% of the nominal (it was not rising above at that time on the 27VM stand). The same restriction also applied during the sea trials of nuclear submarines. During the sea trials, the boat covered almost 4,000 miles, making 29 dives, one of them to a depth of 300 m. The tests were completed on December 1, 1958.

It should be noted that with the limited nuclear power, the submarine reached a speed of 23.3 knots per mile. In terms of rated power, the speed of the boat would be 30.2 knots against 27.2 knots guaranteed by the specification for the ship. During the tests, a number of defects in equipment and systems were identified, mainly associated with leaks. In addition, it turned out that the energy reserve of the active zone of the bow reactor is 25% lower than the calculated one, which required its early replacement.

Sea trials were carried out by a government commission chaired by Deputy Navy Commander V.N. Ivanova. The scientific management of the tests was carried out by A.P. Alexandrov. To the energy section of the commission, headed by I.D. Dorofeev (Navy) included N.A. Dollezhal, V.N. Peregudov, G.A. Hasanov, P.A. Delens, N.M. Sinev, G.A. Gladkov, Yu.N. Koshkin et al. The final act of the commission, later approved by the USSR Council of Ministers, indicated that the atomic submarine created in the USSR was the largest domestic scientific and engineering achievement in the field of submarine shipbuilding. The nuclear submarine was handed over for trial operation, and before it could begin, work should be done to eliminate a number of shortcomings noted by the commission, including and in a power plant.

After long disputes, the Act of the Government Commission recommended the transfer of nuclear submarines to trial operation with the elimination of identified defects. July 16, 1959 the first exit of the boat to the sea took place. During the second exit, the reactor power was increased to 80% and an underwater speed of 28 knots was achieved. After this campaign, which accompanied a number of breakdowns, the captain of K-3 L.G. Osipenko gave the following characterization of a nuclear power plant: “Unreliable, but very tenacious!”

The trial operation of the first nuclear submarine (its tactical number is K-3) continued until the end of 1959. During this time, 3 trips to the sea were made, the capacity of the installation was already rising to 80% of the nominal, various operating modes were checked and worked out. Initially, the operation of nuclear submarines and VM-A installations was very difficult - the boats often returned to the base with failed equipment. The Northern Fleet command began to express the opinion that submarines and reactors were incompatible; official reports on this subject began to arrive at the Central Committee of the CPSU and the government. To assess the quality and reliability level of nuclear submarines, a special commission was organized, headed by the head of the Navy's shipbuilding department, which included the chief equipment designers. A new nuclear submarine of project 658 was allocated for the commission, on which a trip to the Greenland region and back was made in March 1961. In the boat, both of the PUFs failed, and she returned back to the surface on diesels. However, the commission unanimously signed an act with conclusions.

After the completion of the trial operation, the K-3 nuclear submarine began to be used both to carry out special command tasks and to serve in the vast expanses of the oceans, a new type of naval combat activity. In 1962, she made her first trip to the North Pole in the Russian submarine fleet, passing 1294 miles under the ice of the Arctic.

In 1964, when the reactors reached full power, the K-19 submarine showed a speed of 30 knots. By this time, all equipment of nuclear power plants and reactors was brought to the necessary reliability and resource. Thus, a small-sized, high-voltage and highly maneuverable nuclear power plant was created that meets the requirements of a submarine. Based on this nuclear installation, four generations of nuclear installations and their modifications were subsequently created.

In the years 1966-1967. - two autonomous trips with a total duration of 111 days, in 1973-1975. - three trips (a total of 149 days). In total, since the end of the nuclear power plant tests in 1958, the submarine has passed 128,443 miles. The first Russian nuclear submarine (from the end of 1962 it bore the name "Lenin Komsomol") until the navy was withdrawn from military service for nearly 30 years.

Reactor installations "VM-A" were used on all nuclear submarines of the first generation of the Soviet Navy. Until 1967, 55 ships were built on 5 projects (projects 627, 627A, 658, 659 and 675), which differ in purpose and armament. During this period, due to the modernization of systems and materials, the operating life of the reactor and equipment was increased from 4.5 to 25-30 thousand hours, and the core campaign increased from 1.5 to 5 thousand hours.

The creation of a transport nuclear installation for that time was a huge technological progress. But from the point of view of nuclear and radiation safety, it had a number of drawbacks that caused a series of accidents and breakdowns. During the operation of the first generation nuclear submarines, four accidents with water-cooled reactors occurred (K-19 - 1961; K-11 - 1965; K-431 - 1985 and K-192 - 1989). The main disadvantages of nuclear plants of the first generation include a large spatial distribution and a significant amount of the primary circuit, the presence of large diameter pipelines connecting the main equipment, i.e. reactor, steam generators, pumps, heat exchangers, volume compensators, etc. This created serious problems in the organization of protection during emergency depressurization of the primary circuit, as well as in the breakdown of numerous impulse tubes, connecting the first circuit with instrumentation. The accidents were also caused by the low reliability of the equipment, the lack of automation of the control process of the nuclear installation, the low reliability and unreliability of the testimony of instrumentation, as well as the control and protection systems of the nuclear reactor, and the insufficiently reliable control system over the nuclear processes occurring in the reactor.

From the late 1980s, the first generation nuclear submarines began to be decommissioned, and by 1996 all of them were decommissioned from the Russian Navy.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|