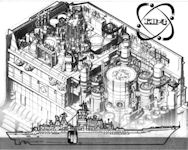

KN-3 Atomic Reactor, Surface Fleet

In 1961, the US Navy received a replenishment - the atomic cruiser Long Beach. Of course, the Soviet leadership began to prepare retaliatory measures. In September 1969, the country's government decided to build the first surface ship in the Soviet Union with a nuclear power plant - a heavy nuclear missile cruiser. In 1971, the Decree of the Central Committee of the CPSU and the Council of Ministers of the USSR on the creation of such an installation for the ship of Project 1144 Orlan was issued. The design of the ship was entrusted to the Northern Design Bureau (SPKB, Leningrad). The construction of the cruiser, its testing and commissioning was carried out by the Baltic Shipyard.

In 1961, the US Navy received a replenishment - the atomic cruiser Long Beach. Of course, the Soviet leadership began to prepare retaliatory measures. In September 1969, the country's government decided to build the first surface ship in the Soviet Union with a nuclear power plant - a heavy nuclear missile cruiser. In 1971, the Decree of the Central Committee of the CPSU and the Council of Ministers of the USSR on the creation of such an installation for the ship of Project 1144 Orlan was issued. The design of the ship was entrusted to the Northern Design Bureau (SPKB, Leningrad). The construction of the cruiser, its testing and commissioning was carried out by the Baltic Shipyard.

Scientific leadership in the design of nuclear power plants was carried out by the Institute of Atomic Energy imeni I.V.Kurchatov (scientific adviser N.S. Khlopkin) under the guidance of academician A.P. Alexandrova, who personally headed the interdepartmental commissions on the problems of the KN-3 reactor.

As the first studies showed, domestic nuclear-powered cruisers needed a two-reactor nuclear steam production unit (NRPP) with a capacity of at least 300 MW each, which was more than three times the capacity of the reactor plants that were on the second-generation nuclear submarines at that time, and twice as much as the icebreaking NRPPs. Accordingly, for the nuclear cruiser, it was necessary to create a new energy propulsion system, which in the future was planned to be used for atomic aircraft carriers.

The creation of a nuclear steam generating installation was entrusted to OKBM (chief designer F.M. Mitenkov). The working draft of the YPPU KN-3, which met all modern requirements for nuclear power plants of surface ships, was prepared by OKBM in 1972. The work in the design bureau, according to the already established tradition, was carried out comprehensively: along with a deep multivariate study of design solutions based on prototypes and calculation justification, all new equipment solutions or its individual units were mastered first in pilot production. Then they were tested in laboratory conditions, subjected to research and analysis, the results of which were carried out the necessary structural improvements or adjustments to the calculation programs.

Considering the positive experience in the creation and operation of icebreaking YPPU type OK-150 and OK-900, as well as taking into account many years of experience in the development, construction and operation of other similar installations, the water-water type reactor was taken as the basis.

The most important requirement for the YPPU being created, taking into account its significant effect on the displacement and seaworthiness of a surface ship, was the requirement for the compactness of the reactor and its minimum possible mass, which is why the new reactor was based on a four-loop block design and layout scheme. The original design of the reactor vessel block proposed by OKBM made it possible to maximally realize the basic requirements of the technical specifications: to reduce the mass-dimensional characteristics of the NPPU while simplifying the design of the reactor and significantly increasing its power.

The increased requirements for nuclear safety of the NPPU determined a number of specific requirements for the design of protection control systems, among which the main was the provision of "self-propelled" - the introduction of compensating gratings (RC) in the reactor core under the influence of its own weight when the electric motor and control device were switched off.

The principle of self-regulation of the reactor was originally laid down in the KN-3 installation due to the negative temperature coefficient of reactivity with power control by changing the flow rate of the secondary water supply. The new reactor did not provide for the creation of its ground-based prototype, therefore, when developing the reactor, volumetric prototyping and modeling were widely used.

New metals and materials were widely used for the new reactor. So, a new VK-2 reactor steel was used for body parts, and stainless steel pipelines were covered with a new anti-corrosion coating based on an organosilicate composition.

The machine-building plant (Elektrostal) had mastered the production of a new reactor core KN-3. For it, fuel elements of a new design with high enrichment uranium, swelling compensators and an increased resource were developed. When creating the KN-3 core, the designers relied on the experience of creating the core zones of OK-900 and OK-650 reactor plants. However, an increase in reactor power required a 1.3-fold increase in the height of the KN-3 reactor core, which entailed various design changes. In particular, the fuel assembly has become integral, consisting of upper and lower working parts.

The laying of the lead ship with the installation of KN-3, called the Kirov, took place on the slipway of the Baltic Shipyard in April 1974. The slipway construction period of the cruiser lasted three years eight months - the ship was launched in December 1977. By this time, the supply of PPU component equipment to the plant was basically completed.

During the installation of the KN-3 reactor, the need for further development of the reactor was revealed. By that time, the operating experience of the OK-900A reactor, as well as refined hydraulic calculations of the heat-return system from the cleaning system, showed that the heat-returning substance to the reactor must be warmed up, since the ingress of a “cold” stream onto the “hot” pipe walls can cause thermocyclic destruction of the collector inside the reactor. As a result of design studies of various options for solving the problem, performed urgently, a heating scheme for the returning coolant in the reactor pipe using the mixer installed in it was adopted. Given the state of the installation of the PUF, it was found advisable to install the mixer from the inside of the reactor (during the subsequent manufacture of the reactors, this scheme was changed to external).

In 1979, active zones were loaded onto the ship. Complex mooring trials of the KN-3 PPU were carried out from April 25, 1980 to May 5, 1980 under a special program. On April 18 and 19, 1980, the first cold physical launch of the stern and bow reactors was carried out.

During tests during natural circulation of the coolant, the PUF reached a power level of 22.5% instead of the 15% stated in the design. The obtained real characteristics of the nuclear installation made it possible, while maintaining the design values ??of the temperature of superheated steam, to reduce the average temperature of the coolant in the core by 8 degrees. In addition, tests have shown that the permissible time of blackout of a power plant (under the conditions of cooling the core) can be increased from 5 minutes (according to the design) to 15 minutes.

Mooring tests of the power plant of the lead ship as a whole confirmed the design specifications of the new nuclear power plant, and some of its parameters exceeded the design ones. The test results testified that the most powerful ship nuclear steam generating unit KN-3 in the USSR was created and was successfully operating.

The cruiser "Kirov" was commissioned in 1980. However, when the cruiser moved to Baltiysk in August 1980, the steam temperature repeatedly decreased by several tens of degrees with increasing hydraulic resistance of the steam generator. The government commission, established to identify the causes of the incident, established that its cause was the ingress of contaminants into the condensate feed system and the steam generator pipes. The Commission ordered the suppliers of the steam turbine plant to take measures to prevent such incidents. Although various incidents took place on ships with the KN-3 YPPU in the future, none of them led to long stops or decommissioning of the ship, to any deviations from the norm of the radiation situation.

Despite the huge mass - the ship has an armored belt of steel with a thickness of 100 mm - thanks to the powerful PPU, it can reach speeds of up to 30 knots. With a hull length of 250 m, the ship's displacement amounted to more than 25,000 tons. The Kirov project 1144 nuclear missile cruiser incorporated all the advanced achievements of Soviet engineering, becoming one of the best in its class. Abroad, the Heavy Nuclear Missile Cruiser (TARK) of the Orlan project was nicknamed the “killer of aircraft carriers”.

Later, the KN-3 YPPU was used in the construction of the Frunze cruiser (commissioned in 1984), the Kalinin cruiser (commissioned in 1988) and the Peter the Great cruiser (commissioned in 1996, until 1991 - Andropov). Each subsequent product was improved in comparison with the previous one in terms of improving the quality of PPU equipment and systems, reliability, safety and ease of use.

In 1988, construction began on the first domestic aircraft carrier ship with a nuclear power plant of the KN-3-43 type at the Black Sea Shipbuilding Plant (Nikolaev), but in 1991 its financing was completely discontinued.

Thus, a series of unique surface ships, heavy nuclear missile cruisers, was created on the basis of the KN-3 nuclear steam-producing installation. Thanks to the nuclear reactor, they have acquired a new valuable quality - virtually unlimited autonomy and range.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|