KLT-40 Atomic Reactor, Surface Fleet

The next stage in the development of the Soviet atomic icebreaker fleet was the creation of a nuclear steam production plant (YPPU) KLT-40. The new reactor was an evolutionary continuation of the well-established OK-900 reactor. In the mid-70s, the Leningrad Central Design Bureau “Bolsudproekt” received a special assignment from the government of the USSR — it was required to develop a draft icebreaking transport vessel with a nuclear installation. It was supposed to carry lighters (up to 74 pieces, each of which weighs three hundred tons) or ISO containers (up to 1328 pieces, 20 feet each). At the same time, independently overcome ice of a meter thickness and move at a speed of at least 20 knots with a ten-meter draft (project 10081).

In 1988, the Sevmorput nuclear-powered container lighter (ALV) with a displacement of 61,000 tons - one of the largest ever built non-military merchant ships with a nuclear power plant - went into operation. The vessel was able to sail on ice with a thickness of up to 1 m (the power of its power plant was 40 thousand liters. From.), For which it used a special shape of the bow contours, inclined sides and original - spoon-shaped - stern contours, thanks to which the lighter carrier does not break the ice , but literally cuts it.

The atomic lighter carrier container ship Sevmorput was intended for unlimited navigation at all latitudes, including tropical ones, with calls to foreign ports. In this regard, the reactor installation for the new ship was designed taking into account the requirements of the International Safety Code for Nuclear Merchant Ships, developed by the International Maritime Organization (IMO). Subsequently, foreign inspectors conducted an inspection check on the compliance of the reactor with IMO codes.

A new reactor, KLT-40, was designed for the ALV at OKBM, which in many ways repeated the OK-900 reactor installation. The decision to use a one-reactor installation was justified by the long trouble-free operation and high reliability of the OK-900 installation. All the main equipment of the reactor was unified with the OK-900 and OK-900A units, which facilitated its manufacture, installation and operation on ships.

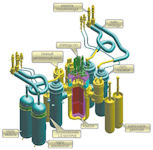

The main circuit of KLT-40 is formed by a reactor, four steam generators, four two-speed circulation pumps of the first circuit, combined into a steam generating unit using power pipes. The steam generating unit is located in the caissons of the metal protection tank. The circulation of the coolant in the main circuit can be carried out in three ways: when the circulation pumps are operating at high and low speeds, when the cooling pump is operating, and also due to natural convection when cooling the reactor. For the first time in KLT-40, a protective shell was provided that meets all applicable safety requirements, a primary circuit protection system from overpressure, a flooding system for the protective shell, etc. are provided. The protective shell is a solid-density partition and is designed for internal pressure, realized during the so-called maximum design basis accident - a rupture with a full cross section of the primary circuit pipeline. The system for reducing the emergency pressure in the containment includes a bubbler tank with fresh water, channels for supplying the vapor-air mixture to the fresh water tank, and safety plugs.

The reactor consists of a casing, a cover of the extraction unit and an active zone assembled from a set of fuel assemblies (FA), which facilitates overloading of the active zone. A fuel assembly is assembled from rod type fuel elements (fuel elements). The combination of fuel rods into assemblies with the release of interchannel water made it possible to increase the velocity of the coolant near the heat-generating surfaces, reduce the power of the primary circulation pumps by reducing the total water flow through the reactor and reduce the reactivity outflows when the coolant circulation changes. The fuel in the KLT-40 reactor uses uranium enrichment of about 40%. The thermal capacity of the KLT-40 reactor is 135 MW.

On the lid of the reactor are installed drives for compensating for excess reactivity and actuators for emergency protection. To increase reliability during beyond design basis accidents, a safety system is provided for introducing a liquid neutron absorber (cadmium nitrate solution) into the reactor.

Although the fundamental provisions for ensuring the safety of ship installations are based on the principles adopted for stationary nuclear power plants (for example, nuclear power units), nuclear ships and ships have their own specifics. For ships, the operation of a nuclear reactor is not only a source of potential danger, but also an opportunity (often the only one) to save a ship at sea and the lives of its crew members. In this case, it becomes permissible for the installation parameters to go beyond the operating limits, in contrast to nuclear power plants, where in such a situation the reactor must be shut down. At sea, the operation of the reactor installation is also possible, at least until the ship returns to base, in the event of the failure of individual safety channels or control systems. Also allowed to start the reactor in the presence of only one source of energy on the ship.

The ceremonial laying of the first section of the Sevmorput nuclear powered lighter carrier (ALV) took place in Kerch at the dock of the Zaliv shipyard. B.E. Butomas in November 1984. February 20, 1986 the ship was launched, where it was completed. On October 26, 1988, the KLT-40 reactor reached criticality.

Before the physical start-up of the reactor, the tightness of the containment was checked. The audit showed that during the largest accident, for example, a large leak of water from the reactor, the leakage of radioactive water from the shell will not exceed 3% per day, which will limit the flow of radionuclides into the atmosphere to acceptable values.

Then the reactor was brought to a power level sufficient for operation of the steam turbine unit, followed by a check of the unit in stationary and transient modes of operation, as well as the execution of algorithms for triggering emergency protection or emergency power reduction when disconnecting individual systems. Further, when the reactor was operating at full power, measurements of the effectiveness of biological protection were carried out, which showed that the gamma and neutron radiation levels behind the protection correspond to the design values, and the dose rate on board the vessel does not exceed 5-10 µR / hour.

On December 31, 1988, after completion of sea trials, ALV Sevmorput was put into operation. Confidence of the designers in the reliability of the KLT-40 nuclear power plant was manifested already in the fact that the ship immediately went on a commercial flight from Odessa to Vladivostok. January 11, 1989 a ship with almost 30 thousand tons of cargo left the port of Odessa and moved to the Bosphorus. Despite the measures taken, a number of incidents occurred along the way. So, on January 18, seawater fell into the second loop of the reactor, and on the night of January 20, emergency reactor protection was triggered due to the interruption in the supply of feed water to the steam generators caused by a malfunction of the automation and the human factor.

During the passage of the nuclear-powered ship through the equator, the temperature of sea water was 30 degrees, which was higher than the design for a nuclear power plant. Due to the vacuum drop in the main capacitor, an emergency signal was received to reduce the power of the reactor installation, because of which it was necessary to reduce the speed of the ship.

In February, after a second seawater re-entry into the second circuit of the reactor, a set of volunteers was announced to search for the source of leaks, but could not be found. March 3, the ship embarked on a distant roadstead of the port of Vladivostok.

Over the course of the voyage, foreign individuals repeatedly carried out both a remote analysis of the radiation situation and sampling from the ship, as well as inspection visits on board, but there were no complaints about the radiation situation. Many years of experience in operating the ship on international lines and in the Arctic have demonstrated the wide possibilities of using ALV in any region of the oceans.

The introduction of year-round navigation beyond the Arctic Circle required the creation of a fundamentally new generation of icebreaking vessels, with the possibility of sailing in the mouths of the northern rivers. Already the first regular flights to the Yenisei estuary showed: starting in January, diesel icebreakers operate here at the limit of their technical capabilities. Their capacity of more than twenty thousand horsepower was not enough for fast and reliable pilotage. It was then that experts first started talking about the need for Siberian rivers to build new icebreakers with low draft and a nuclear power plant. As a result, the USSR began the construction of atomic icebreakers of Project 10580 with limited draft, designed to escort ships to the mouths of Siberian rivers.

On November 12, 1984, a contract was signed with the Finnish company Vyartsilya Marina for the construction of two nuclear-powered ships Taimyr and Vaigach. The new machines received their names in honor of the legendary icebreakers operating in the Arctic at the beginning of the 20th century.

The contract stipulated that icebreaker hulls would be built in Finland, and Soviet propulsion systems and equipment were installed on ships. The keel of the Taimyr icebreaker was laid in January 1985. In 1988, the hull was launched and towed to Leningrad at the Baltic Shipyard named after Sergo Ordzhonikidze for the installation of YPPU.

On new icebreakers, a KLT-40M nuclear power plant with a capacity of 50 thousand hp was installed, which allows the icebreaker to go through the ice two meters thick. With an ice thickness of 1.77 meters, the speed of the icebreaker is 2 knots. The icebreaker can operate at temperatures up to -50 ° C.

On June 30, 1989, the Taimyr icebreaker was put into operation and became part of the fleet of the Murmansk Shipping Company. On July 25, 1990, the icebreaker "Vaigach" was put into operation and became part of the fleet of the Murmansk Shipping Company. In 1989, its hull was towed to the USSR for completion in Leningrad, where a nuclear power plant based on the KLT-40M reactor was installed. Further operation of the Taimyr and Vaigach nuclear icebreakers at the mouth of the Yenisei convincingly demonstrated the timeliness of their construction, the efficiency of the icebreakers in the northern region and their environmental benefits.

In December 2015, the icebreaker Vaigach set the speed record for the latest passage from Cape Dezhnev along the Northern Sea Route to Bely Island. He covered 2250 miles in 185 hours at an average speed of 12.5 knots.

In 2017, Rosatomflot’s specialists, together with the design bureau of Afrikantov OKB JSC, completed the modernization of the nuclear power plants of the Vaigach and Taimyr nuclear icebreakers, and their life was extended to 200,000 hours.

On February 16, 2018, the Vaigach icebreaker broke the record for the longest life of a nuclear power plant, set by the Arktika nuclear icebreaker in August 2008. The new record amounted to 177.205 thousand hours (the previous value - 177.204 thousand hours).

On May 18, 2009, the Baltic Shipyard in St. Petersburg launched the slipway assembly of the head unit of a floating nuclear power plant, which is being built under the design of Iceberg Central Design Bureau. The floating power unit has become another aspect of the KLT-40 reactor in the KLT-40S modification.

Floating Nuclear Power Plant (FNPP) is a new generation energy source created on the basis of Russian nuclear shipbuilding technologies. The main element of the station is the floating power unit (PSU) of project 20870. This is a non-self-propelled vessel on which power equipment for generating electric and thermal energy is located. A PSU is being built at a shipyard and delivered by sea to the FNPP location. Only auxiliary facilities are being built on the site.

The dimensions of the FNPP, which received the name "Academician Lomonosov", are quite large and are 140 meters long and 30 wide, its displacement is 21.5 thousand tons. The FNPP building is fully welded, divided by partitions into compartments that form two blocks - residential and technological. In the technological are reactors and turbines, a compartment for handling nuclear fuel and all the necessary auxiliary systems and equipment.

“Academician Lomonosov” is equipped with two KLT-40S reactor units, the reliability of which is confirmed by thousands of reactor hours produced by reactors of this type. KLT-40C reactors are equipped with modern safety systems, including those based on passive principles of operation that are not dependent on human participation and automation. The power capacity of the FNPP is 70 MW plus 50 Gcal / h of thermal energy, which is enough to support the life of the city with a population of about 100 thousand people. The FNPP can be operated without fuel unloading for 12 years, and the designated service life of the station is 40 years. The FNPP is designed with a large margin of safety, which exceeds all possible threats and makes nuclear reactors invulnerable to tsunamis and other natural disasters. Nuclear processes at a floating power unit meet all IAEA requirements and do not threaten the environment. At FNPP, nuclear fuel of lower enrichment is used - less than 20%.

At rated thermal power, each unit of the KLT-40S reactor installation provides the generation of 240 tons per hour of steam with a temperature of 290 degrees. Electricity is supplied with a voltage of 10 kV, which is most advisable for creating power lines.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|