Medium Protected Vehicle (MPV)

Veicolo Tattico Medio Multiruolo [VTMM]

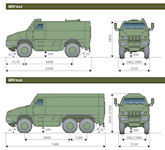

The new 4x4 Medium Protected Vehicle (MPV) is a wholly European development. The MPV fits between the light protected vehicle (LMV, Eagle) and wheeled armored personnel carriers such as Centauro/Freccia and Boxer. The MPV design exploits the technical expertise of two of the major European armoured vehicle manufacturers, Iveco DV and Krauss- Maffei Wegmann (KMW) of Germany. A formal co-operation agreement between the two companies was signed in June 2010. The MPV comes in 4x4 and 6x6 configurations.

The Italian Army ordered an initial batch of 12 Medium Protected Vehicles (MPVs) in the ambulance configuration from IVECO Defence Vehicles. Under the December 2010 contract, the MPVs, referred to as the Veicolo Tattico Medio Multiruolo [VTMM] within the Italian Army, are expected to be delivered between 2011 and 2012. Funding permitted, the total MPV requirement is for up to 1,400 vehicles, as the Italian Army is expected to use the MPV for a wide range of roles.

IVECO Defence Vehicles closely researched the demands placed on protected multipurpose vehicles by the wide range of operations which they are required to undertake. Based on the output of this research, and on the company’s own extensive experience of the market sector, a program was initiated to develop an innovative and highly protected Medium Protected Vehicle (MPV). The new MPV range is available in 4x4 and 6x6 versions with a GVW from 18 tons to 25 tons.

The German 6x6 25 ton version of the MPV was unveiled at Eurosatory 2008; the Italian 4x4 18 ton version was displayed at Eurosatory 2010. The MPV combines a ballistic steel protected crew cell with the off-the-shelf chassis widely used in the Trakker product line, ensuring worldwide support through Iveco's worldwide logistics support network.

The Medium Protected Vehicle was designed to fill a wide variety of roles including:

- Crew carrier

- Command, reconnaissance and liaison vehicle

- Ambulance

- Logistic transport

- Artillery tractor

- Crew protection against small arms fire, shell splinters, anti-tank mines and improvised explosive devices (IEDs)

- High mobility on roads and cross country

- Large protected payload volume and high payload

- Transportability

- Towing capacity

- Reliability and maintainability and was

The transparent armor is designed to match the protection provided by the rest of the vehicle providing the overal vehicle with the ability to withstand threats up to STANAG 4569 level 3. Protection against mine and IED attack up to STANAG 4569 Level 3 is provided both through the dewsing of the hull, with its large stand-off, underbody deflector plates and blast energy management system, and through a series of design features.

Large tyres fitted with run-flat inserts optimise absorption of blast energy, while deflector plates lining the whell arches maximise energy dissipation. All occupants are provided with specially designed shock dampened seats which are suspended on elastic mounts, avoiding direct transmission of blast shock to the crew. The seats incorporate moulded padding and five point seat harnesses to reduce sudden body movements caused by both the primary (rising) and secondary (falling) effects of blast. Specially designed wrap-around head-rests provide protection from whiplash.

The roof of the MPV is fitted with a lockable hatch which can be opened from both inside or outsude for safety reasons. The Vehicle roof structure is can be accept a variety of weapons depending on customer requirements, including 7,62mm or 12,7mm machine gun and 40mm grenade launcher. Particular care has been taken to address human factors in the design of the crew cell providing ergonomically sound and confortable working positions for all occupants, catering for 5th to 9th precentile soldiers. The Vehicle complements this by providing high level of vibration control and shock absorption. The Vehicle’s controls are designed to provide a careful balance of automation and lightness of touch, making the vehicle responsive and easy to handle.

High reliability, ease of maintenance and low through life costs were key considerations during the design of MPV. The vehicle benefits particularly from Iveco’s engineering experience on its truck range which has allowed incorporation of a number of innovative design features. Built in and external diagnostics allow timely identification of impending malfunctions, allowing preventive maintenance to be undertaken, whilst the facility to collect vehicle data allows effective whole fleet management. The use of COTS main assemblies such as the gearbox and engine ensures that performance and reliability have been proven over many millions of road miles in demanding environmental conditions.

This provides an outstanding level of reliability and consequently excellent fleet availability. The design imperative to minimise running costs has led to a reduction in Level 1 maintenance requirements, with scheduled maintenance intervals being double those for comparable vehicles. MPV is fitted with a 2nd generation CANBUS which links the electronic control units of the engine, gearbox and ABS. By interrogating the system with a diagnostic tool, the maintainer can gather diagnostic and prognostic information in real-time, enabling pre-emptive maintenance to be planned.

Ease of maintenance has received a very high priority, with ready access being provided to undertake checks and routine servicing tasks, and maximum use being made of repair by replacement. All Level 1 checks can be carried out without any dismantling of assemblies, or use of special tools, while all Level 1 maintenance can be undertaken by the crew, using onboard tools.

In its basic configuration, MPV is capable of fording depths of 0.75 m unprepared by virtue of its waterproof electrical system. This can be extended to a depth of 1.2 m by adding extensions to the air intake and exhaust. MPV’s weight and size ensure that it is highly transportable: by rail transport on standard flatbeds; by RO-RO ferry; by air in C130J with preparation and in heavy strategic airlift such as C-5, C-17, A400M.

| 4 x 4 | 6 x 6 | ||

|---|---|---|---|

| Dimensions | |||

| Wheelbase | mm | 4000 | 3000/1390 |

| Track (front and rear) | mm | 2062/2081 | 2062/2081 |

| Max width | mm | 2530 | 2530 |

| Overall length | mm | 6500 | 7400 |

| Height (cabin top line) | mm | 2850 | 3080 |

| Min. height (under front axle) | mm | 400 | 400 |

| Min. height (undercarriage) | mm | 500 | 500 |

| Front/rear incidence angles 35° /35° | 35° /35° | ||

| Mass and payload / towing capacity | |||

| Total mass on the ground | kgs | 18000 | 25000 |

| Tare | kgs | 15000 | 20500 |

| Payload | kgs | 3000 | 4500 |

| Gross Combination weight | kgs | 40000 | 40000 |

| Performance | |||

| Max speed | km/h | >90 | >90 |

| Max longitudinal slope gradient | >60% | >60% | |

| Max transverse slope gradient | 30% | 30% | |

| Turning circle (kerb to kerb) | m | 17.5 | 18 |

| Fording depth (without preparation) | mm | 750 | 750 |

| Fording depth (with preparation) | mm | 1200 | 1200 |

| Power/weight ratio kW/t | 15 (20hp/t) | 13.3 (17hp/t) |

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|