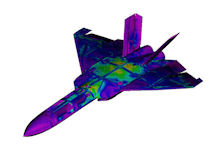

Fifth Generation Aerial Target (5GAT)

The new Fifth Generation Aerial Target (5GAT) air targets, developed by Sierra Technical Services since 2006, will be able to imitate fifth-generation enemy fighters. On June 20, 2018, the American company Sierra Technical Services completed the Critical Design Review for the fifth-generation 5GAT air target project. Now the company can begin to assemble the first demonstrator of the new target. Its first flight is scheduled for spring 2019.

DOT&E has been investigating the need for an aerial target to adequately represent the characteristics of Fifth Generation threat aircraft in light of the emergence of threat aircraft like Russia’s PAK-FA and China’s J-20. The Fifth Generation Aerial Target (5GAT) study effort began in 2006 and examined the design and fabrication of a dedicated 5GAT that would be used in the evaluation of U.S. weapon systems effectiveness.

Since then, DOT&E and TRMC have invested over $11 Million to mature the government-owned design. The Department provided funding to complete the final design, tooling, fabrication, and flight tests. The prototyping effort will provide cost-informed alternative design and manufacturing approaches for future aerial target acquisition programs.

The 5GAT team – comprised of Air Force and Navy experts, retired Skunk Works engineers, and industry experts – completed the preliminary design in 2016. The fully owned Government design includes the aircraft outer mold line, internal structures, loads analysis, propulsion, and subsystems. Also, the team built one full-scale, flight-representative wing that will be used for structural load tests and a system integration laboratory. The Department provided funding to complete the final design, tooling, fabrication and flight tests.

The prototyping effort will provide cost-informed alternative design and manufacturing approaches for future air vehicle acquisition programs. This data can also be used to assist with future weapon system development decisions as well as T&E planning and investment, and will support future T&E analysis of alternative activities. It will also demonstrate reduced signature, basic aerodynamic performance, and provision for special mission systems.

With the service of the J-20 and the mass production of the Su-57, the Chinese and Russian fifth-generation stealth fighters are already an imminent threat to the US Air Force. The most important thing is to increase the F-22 and F-35 participation in the imaginary enemy training. In addition to strength, the US Air Force has also spent huge sums of money to launch the 5GAT fifth-generation stealth target aircraft project, providing a full-scale target aircraft capable of simulating the real radar and infrared signal characteristics of stealth fighters for live-fire training and weapon testing.

After the QF-4 was retired in 2017, the US Air Force's active full-size target is a QF-16 modified with a retired F-16 fighter. The F-16 not only has a greater maneuverability than QF-4, but also provides a more realistic target for live-fire testing of air-to-air missiles. In addition, its size is smaller than QF-4, and the radar cross-sectional area is smaller. Also lower, more importantly, the QF-16 can share parts with the F-16 of the US Air Force's first-line units, reducing maintenance and operating costs. However, no matter how excellent the QF-16 is, the radar cross-sectional area is low, and it is not always a stealth target.

The US Air Force officially launched the fifth-generation stealth target aircraft project in 2011. A design project proposed by a group of aviation engineering students from the US Air Force University was selected and developed by Sierra Technical Services. The key design was June 20, 2018.

Sierra released an interesting photo showing that the internal structure of the 5GAT prototype in manufacturing is similar to the plastic assembly model, completely abandoning the all-metal semi-hard shell structure of the traditional aircraft, and using carbon fiber reinforced composite (CFPR) to make the whole. Hard shell structure. There are only three integral sidings in the front fuselage of the aircraft. There are two S-shaped inlets and reinforcing beams integrally formed by composite materials in the middle of the fuselage. There are only a few reinforced spars and ribs inside the wing and a composite composite. Material wing skinned. the 5GAT structure is so simple is to minimize the manufacturing cost. As a consumable target machine, the machine needs to reduce the manufacturing cost as much as possible.

First, the 5GAT design has a tailless delta layout, and the cancellation is adopted. Flat tail to reduce the number of operating airfoils and actuators, the machine is close to QF-16 in size, with a take off weight of 5.4 tons, and two used J85 afterburning turbojet engines installed.

Second, the 95% of the 5GAT structure is made of carbon fiber reinforced composite material, which greatly reduces the number of parts and manufacturing cost through integral forming process. The simple hard shell reinforcement structure of the machine eliminates the complicated fuselage frame in the traditional all-metal semi-hard shell structure. , longitudinal beams, spars, ribs, skin design, greatly reduce the labor costs of manufacturing and assembly, know that the assembly of modern aircraft can not get rid of manual work, so the more complex the aircraft structure, the more the number of parts, the machine The cost of manufacturing and assembly is higher. Lockheed has built an all-composite structural fuselage and tail fin for a Do-328 in a test project. The results show that the original metal fuselage and tail have more than 3,000 parts, while the composite fuselage and The number of parts in the tail is only 300.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|