|

The BCT’s next mission is a movement to contact with a line of departure (LD) time of 2300 hours. The brigade executive officer (XO) opens the 1500-hour maintenance meeting requesting combat power slants from each major task force. To his dismay, the overall readiness posture for the BCT is lower than anticipated: 63% for tanks and 72% for Bradleys. Perplexed, the brigade XO asks the forward support battalion (FSB) support operations maintenance officer why the numbers are low. “There are only six non-mission capable (NMC) tanks and four NMC Bradleys on the deadline report," he shouts. The maintenance officer, with a look of astonishment, shakes his head and replies, “Sir, I have no idea why!”

Although there may be several contributing factors to this situation, there are three primary indicators that leaders can examine to accurately address their maintenance posture. If a BCT shows positive trends in preventive maintenance, standard army management information systems (STAMIS) synchronization and disk turn-in rates, and the BCT maintenance meeting, inductive evidence from the National Training Center indicates that they have systematically enhanced their LD combat power.

Preventive Maintenance

The bottom line is that preventive maintenance is important! Done regularly and done right, it saves lives, dollars, and time. The 5988-E/DA Form 2404 is the first link in the chain of information that gets your equipment repaired or replaced. The Army’s preventive maintenance system is difficult to execute and assess because it is dependent on the quality of operator/crew level inspections. Nonetheless, it is imperative that this critical function be performed to standard as outlined in Chapter 12, DA PAM 738-750, Functional Users Manual for the Army Maintenance Management System (TAMMS). Units must incorporate quality control at every level to ensure that a complete preventive maintenance checks and services (PMCS) is performed. The 5988-E/DA Form 2404 (equipment inspection/maintenance worksheet) has three functions:

1. It is a record of faults found during an inspection. These faults include PMCS, maintenance activity inspections, diagnostic checks, and spot checks.

2. It shows faults and repairs required for estimated cost of damaged reports.

3. Its shows battle damage and assessment and repair (BDAR) performed.

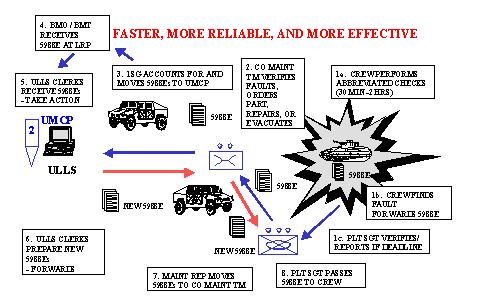

Keeping track of the 5988-Es as they flow through the system is a major challenge. Units predominantly collect and distribute 5988-E/DA Forms 2404 during logistics release point (LRP) operations. Successful units make the company first sergeant responsible for tracking the 5988-Es. Figure 1 can be the basis of an effective 5988-E flow checklist.

FIGURE 1: Flow technique for 5988-E/2404s

Even though unit leaders may choose not to require a daily 5988-E if there are no faults, operators still must perform 10-level checks and first line leaders should spot check often. First line leaders must also ensure that the 5988-E is filled out to standard. Common deficiencies are lack of annotated corrective action taken and lack of a maintenance supervisor signature. Unit leaders must check the completed form before forwarding to maintenance personnel. Unit personnel must train to this standard at home station. If soldiers care about the process and develop pride in their equipment, they will perform proper PMCS and improve the quality of the 5988-E/DA Form 2404 submission.

STAMIS Synchronization

Once the unit level logistics system - ground (ULLS-G) clerk receives the supervisor-verified 5988-E/DA Form 2404 with faults verified by a mechanic and the correct parts annotated, he or she enters this data into the ULLS-G computer. BCT maintenance managers must then get the data into the maintenance system via disk. Disk synchronization is a three-step process. To be successful, maintainers cannot deviate at any step. Without proper disk synchronization, deadlined vehicles may appear on the 026, but there will be no parts status available. This critical information is essential to maintenance managers at all levels in order to return the deadlined vehicle back into the fight.

The process is straightforward:

FIGURE 2: ULLS-G disk synchronization flow chart.

When programming the disk-drop times in your concept of support, the FSB must take these synchronization factors into consideration. Typically, disk drop time windows are established to ensure that every customer in the BCT is processing their supply and maintenance disks at least twice daily. These programmed windows must encompass the appropriate amount of time necessary to complete the proper disk sequencing. This means that the standard Army retail supply subsystem (SARSS) clerk cannot be lackadaisical when processing customers’ supply data. Returning status disks or data back to the customer quickly will allow the client time to process their maintenance disk and turn it in to shop office standard Army maintenance system (SAMS-1). Depending on how your BCT decides to transmit data, these windows can be anywhere from two to four hours long to allow time for a pass in both supply and maintenance information.

FIGURE 3: Sample timeline for critical management functions.

Maintenance Management Procedures

The single most important tool in the BCT for conquering maintenance issues is an effective BCT maintenance meeting. The goal of the maintenance meeting is to provide a clear picture of the BCT’s current maintenance posture and to set the conditions for producing maximum combat power for the next mission. Several factors determine how effective a BCT’s maintenance meeting will be, but none have a more positive effect than the attendance and active participation of the BCT leadership. The brigade XO should chair every meeting, establish meeting standards, and reemphasize those standards to the units who either fail to attend or are unprepared to brief their maintenance status. If maintenance is a priority to the BCT leadership, it will become a priority to the units within the brigade.

In order for the maintenance meeting to run efficiently, units must consider the following:

- TIME: METT-TC always drives the maintenance meeting time, but the time must be supported by the established supply and maintenance disk-drop windows in order to produce the most current 026 possible. Units should attempt to use a 026 print that is no older than eight hours. The unit should also conclude the meeting with enough lead-time to request and push critical Class IX parts on the evening LOGPAC coming from the DSA.

- LOCATION: Establishing a standard meeting location alleviates confusion. Units know where and, generally, when the meeting occurs even if communications break down. Having the meeting at the BSA allows the unit attendees to conduct further business, maximizing the time that task force maintenance managers have to build combat power.

- AGENDA: A posted agenda that supports the BCT commander’s priorities for the next mission and focuses on building combat power is essential. Units should know exactly what they are expected to brief. Information should include current combat system slants, expected slants, and numbers of circle-X combat systems. The administrative data for all attendees is given up front so units can leave after briefing their task force status.

- ATTENDEES: Aside from the BCT XO, the most important attendee is the FSB support operations officer. He is responsible for taking action on any shortcomings that surface during the meeting. Other required attendees should include the support operations maintenance officer (MATO), material management center (MMC) representative, brigade S4 and Army oil analysis program (AOAP) representative, task force XOs, each battalion maintenance officer (BMO) or technician (BMT), separate company XO/ motor sergeants, tech supply officer (TSO), maintenance company shop officer, and representatives from logistics assistance office (LAO) and combat service support automation management office (CSSAMO).

In order for direct support (DS) maintenance managers to be as prepared for the meeting as supported units, the MATO, MMC representative, shop officer, and TSO must conduct a pre-maintenance meeting to synchronize DS efforts and resolve issues prior to the BCT maintenance meeting. Important actions accomplished at this meeting include the following: a thorough scrub of the 026 print, identification of critical Class IX awaiting pickup, required Class IX available on the authorized stockage level (ASL), jobs requiring a DS work order or direct support, identification of units requiring backup or reinforcing organizational maintenance, and acquisition of the latest status on required non-stockage list (NSL) parts.

The final “must have” during a maintenance meeting is the contract. A contract, simply put, is a closed loop reporting system. Contracts specify who is going to accomplish specific actions, when these actions will be completed, and who will report status of these actions. Contracts are tracked and briefed daily by the support operations officer or MATO. Identifying new contracts during the maintenance meeting, holding personnel accountable to provide current status daily, and closing out of contracts prior to and during follow-on maintenance meetings are fundamental to the success of the maintenance mission. Do not consider every issue a contract. Focus on those actions over and above normal day-to- day operations.

On the battlefield your BCT may be as powerful as Achilles, the greatest of the Greek warriors in the Trojan War. However, if you allow poor procedures and management from the organizational through direct support levels, maintenance will quickly become the lance that strikes you in the heel and renders your brigade combat ineffective.

|