CHAPTER 11

COMBAT SERVICE SUPPORT OPERATIONS

The role of combat service support in any military unit is to sustain the force for continuous combat operations. At company level, regardless of the type battalion or brigade, the company commander has ultimate responsibility for CSS. The executive officer, the first sergeant, platoon leaders, and platoon sergeants are the primary CSS operators for the antiarmor company. The light infantry battalion's antiarmor platoon is supported logistically by the battalion headquarters company 1SG or XO, or the combat trains command post. The SBCT antiarmor company CSS operations are discussed in Section VII. Only the significant differences in combat service support to the SBCT antiarmor company will be addressed.

Section I. AIRBORNE, AIR ASSAULT, AND LIGHT INFANTRY BATTALION CSS

Combat service support requirements range from sustaining platoons and companies operating independently to sustaining battalions operating in restrictive terrain with little or no access by road. Requirements for CSS vary, depending on the unit mission. Commanders, mainly through their XOs, S4s, and S1s, plan and employ CSS assets to ensure success of missions. The constraints inherent in the CSS organization require infantry commanders to rely on their ingenuity, endurance, and initiative to succeed in rugged environments.

11-1. DEVELOPMENT OF THE CSS PLAN

The infantry battalion commander, battalion S4, and antiarmor company commander (or platoon leader) plan and implement antiarmor CSS operations. A CSS team, consisting of the infantry battalion S4, battalion support platoon leader, company XO, company 1SG, company supply sergeant, antiarmor platoon sergeants, and antiarmor squad leaders, implements antiarmor company CSS plans. Antiarmor leaders plan and make CSS decisions to accomplish their assigned missions according to guidance from higher headquarters and SOPs. Unit SOPs should address planning, implementation, and responsibilities in detail and should standardize as many routine CSS operations as possible.

11-2. GENERAL GUIDELINES

In infantry battalions, CSS assets are assigned to the headquarters and headquarters company (HHC). The HHC commander then provides each maneuver company with personnel, equipment, supplies, and other support functions, including petroleum, oils, and lubricants (POL) and transportation requirements. The battalion sets the resupply schedule (usually by SOP) and organizes the logistic package (LOGPAC) to support the battalion. The light infantry battalion's antiarmor platoon is supported by a LOGPAC controlled by the HHC 1SG or XO.

a. Within this support structure, the antiarmor company (or platoon) must plan, prepare, and execute its portion of the CSS plan. Concurrent with other operational planning, the antiarmor unit develops its CSS plan during mission analysis and refines it when war-gaming courses of action. CSS rehearsals are normally conducted at both battalion and company levels to ensure a smooth, continuous flow of materiel and services.

b. The antiarmor company's (or platoon's) basic CSS responsibilities are to report requirements and request support through the appropriate logistical channel, and to ensure that CSS operations are properly executed when support elements arrive in the company area. The antiarmor company 1SG or XO is normally in charge of these functions, with guidance and oversight provided by the antiarmor company commander. They must submit accurate personnel and logistical reports, along with other necessary information and requests.

11-3. RESPONSIBILITIES

The antiarmor company commander is responsible for the coordination and execution of CSS functions within the company. This includes reporting current status, requesting supplies or support, and conducting effective CSS operations within the unit. The primary CSS functions required by the company include CASEVAC, resupply operations, maintenance activities, and personnel service support. The following company and platoon personnel have CSS responsibilities.

a. Company Commander. The company commander ensures that CSS operations sustain his antiarmor company's fighting potential. He integrates CSS activities into the tactical plan and provides guidance to the CSS operators. He tailors his CSS operations to meet the tactical plan.

b. Company Executive Officer. The company XO, in addition to his tactical responsibilities, coordinates and supervises the company's logistical effort. During planning, the company XO receives status reports from the platoon leaders, platoon sergeants, and 1SG; he reviews the tactical plan with the company commander to determine company CSS requirements; and he coordinates the company's needs with the battalion S4. During execution, the company XO is at the second most important place on the battlefield, as determined by the antiarmor company commander. The XO also performs the following CSS functions:

|

c. First Sergeant. The1SG is the primary CSS operator for the company. He executes the company CSS plan and supervises the company trains. He makes sure the company XO and battalion CTCP receive current status reports from all subordinate units; he helps the company XO prepare reports and requests to battalion (or does this by himself); and he helps the company XO or company commander prepare paragraph 4 of the OPORD.

(1) The 1SG receives, consolidates, and forwards all logistics, personnel, and casualty reports to the CTCP. He supervises the CASEVAC, evacuation of EPWs, and the evacuation of damaged equipment. He also establishes and supervises company resupply activities and monitors company maintenance activities.

(2) The 1SG orients new replacements and assigns them to antiarmor squads and antiarmor platoons IAW the company commander's guidance.

(3) The 1SG gets his information from the platoon sergeants and squad leaders as well as the senior medic. These NCOs are responsible for providing all CSS reports IAW the antiarmor company and battalion SOP.

(4) The 1SG also performs the following CSS functions:

|

d. Supply Sergeant. The supply sergeant is the company representative in the battalion field trains.

(1) He assembles the LOGPAC and moves it forward to the company. He assists the 1SG with resupply and coordinates the company's CSS requirements with the battalion support platoon leader, battalion S4, and the HHC commander. The supply sergeant may control the medical ambulance when it is unable to remain forward with the antiarmor company. He monitors the tactical situation and adjusts the CSS plan as appropriate to meet the tactical plan and the company commander's intent. He forecasts the company's consumption of food, water, ammunition, and batteries, based on the operation.

(2) The supply sergeant also performs the following CSS functions:

|

e. Platoon Sergeant. Each PSG in the company performs the following CSS functions:

|

f. Senior Medic. The antiarmor company's senior medic and other medics are assigned to the HHC, but are attached to the company. The senior medic's responsibilities include the following:

|

Section II. TRAINS

In order to meet the intent of both the brigade and battalion commanders (two levels up), each organization at the antiarmor company level and higher must have a logistical focal point. This focal point is generally described as the "trains." The types of logistical trains are described in this section.

11-4. BATTALION COMBAT TRAINS

The battalion combat trains are normally positioned close enough to the FLOT to be responsive to forward units but beyond the range of enemy direct fires. The trains are positioned based upon the factors of METT-TC.

11-5. BATTALION FIELD TRAINS

The battalion field trains are normally positioned in the brigade support area. The antiarmor company, with the other maneuver companies, normally locates its supply section and any corresponding vehicles in the battalion field trains.

11-6. COMPANY TRAINS

The most forward CSS element is the company trains, which provide vehicle recovery, medical aid, and maintenance services. It is the focal point for company sustainment operations. The size, composition, and location of the company trains vary depending upon an analysis of the factors of METT-TC. The trains normally operate one terrain feature to the rear of the company. This gives the antiarmor company virtually immediate access to essential CSS functions while allowing the trains to remain in a covered and concealed position. The antiarmor company commander must consider the required security of his trains and the size of the force he plans to use. The 1SG normally positions the trains and directly supervises CSS operations.

11-7. TRAINS SECURITY

Because security of CSS elements is critical to the success of the company missions, the company commander must develop plans for continuous security operations. Where feasible, the commander may plan and execute a perimeter defense. The trains, however, may lack the personnel and combat power to conduct a major security effort. In such situations, they must plan and implement passive security measures to provide protection from enemy forces.

11-8. COMMUNICATIONS

Fast, reliable communications are critical to the CSS effort. Whether as directed by higher headquarters or as needed to support the antiarmor company mission, the 1SG must be able to instantly report the company's status, including combat losses, and to send resupply and support requests. In the light infantry battalion, the antiarmor platoon sergeant performs this same function.

a. As in all tactical situations, FM radio and FBCB2 are the fastest and most frequently used means for transmitting CSS requests and reports. The battalion administration and logistics (A/L) net is used for most CSS traffic, but the company may not have enough authorized FM radio systems to monitor it. When this is the case, a higher NCS must enter the company net to contact the company. Another type of problem can arise when a company enters the A/L net. The transmission of one company may transmit over another company's report or request. Unit SOPs must specify procedures to be followed in this type of situation to ensure that the battalion field and combat trains receive all transmissions on a timely basis. Units equipped with FBCB2 (for example, an SBCT) can transmit logistics reports digitally.

b. As an alternative, the company can send CSS reports and requests by messenger or wire. Messengers are slower than FM radio transmission, but more secure. Wire communications are also very secure, but are strictly limited in range and coverage. In situations where use of the FM radio communications is not possible, a messenger can be sent with the resupply or evacuation vehicle. For sending lengthy or complex reports and requests, messenger or wire (or digital message) is better than FM radio transmission.

Section III. RESUPPLY OPERATIONS

The antiarmor company commander considers the factors of METT-TC in determining the best means of resupplying his company. Resupply operations are generally classified as routine, emergency, or prestock (or cache). Cues and procedures for each method should be specified in a company SOP and must be rehearsed.

11-9. CLASSES OF SUPPLY

Figure 11-1, shows the classes of supply.

a. Class I. Class I includes rations, water, and ice as well as gratuitous issue items related to health, morale, and welfare. Class I supplies are automatically requested from the battalion on the daily strength report. Rations are prepared in the field trains and delivered with the LOGPAC. Meals, ready to eat (MREs) stored on the antiarmor company or its platoon's vehicles are eaten only when Class I resupply, including mess operations, cannot be accomplished.

b. Class II. Class II includes clothing, individual equipment, MOPP suits, tentage, tool sets, and administrative and housekeeping supplies and equipment. Expendable items such as soap, toilet tissue, and insecticide are distributed during LOGPAC operations.

c. Class III. Class III covers POL products. Class III requests normally are submitted to the combat trains. POL includes both bulk and package products. Examples of bulk products include fuel such as Army common fuel (JP8) and motor gas (MOGAS). Package products (oil and lubricants) are requested and received like Class II and Class IV items.

d. Class IV. Among the items in Class IV are construction materials, pickets, sandbags, and concertina wire. Company SOP specifies the combat load of Class IV items for each vehicle.

e. Class V. Class V covers all types of ammunition and mines, including explosives such as C4.

f. Class VI. Class VI includes personal-demand items ordinarily sold through the exchange system. Examples are candy, soaps, cameras, and film. When a PX is not available, Class VI support is requested through the battalion S1.

g. Class VII. This supply class includes major end items such as vehicles. Class VII items are issued based on battle loss reports. Ready-to-fight weapons systems are sent forward with the LOGPAC.

h. Class VIII. Class VIII covers medical supplies. Combat lifesaver bags and first-aid kits are replaced on a one-for-one basis at the battalion aid station (BAS).

i. Class IX. Class IX includes repair parts and documents required for equipment maintenance operations. Repair parts are issued in response to a specific request or are obtained by direct exchange of repairable parts, to include batteries for night vision devices and man-portable radios. In combat situations, exchange and controlled substitution are the normal means of obtaining Class IX items.

j. Class X. Class X includes materials to support nonmilitary programs such as agriculture and economic development. Instructions for request and issue of Class X supplies are provided at division level or higher.

k. Miscellaneous. This category covers anything that does not fall in one of the existing classes of supply.

Figure 11-1. Classes of supply.

11-10. ROUTINE RESUPPLY

Routine resupply operations cover items in Classes I, III, V, and IX, as well as mail and any other items requested by the antiarmor company (or platoon). Whenever possible, routine resupply should be conducted daily, ideally during periods of limited visibility.

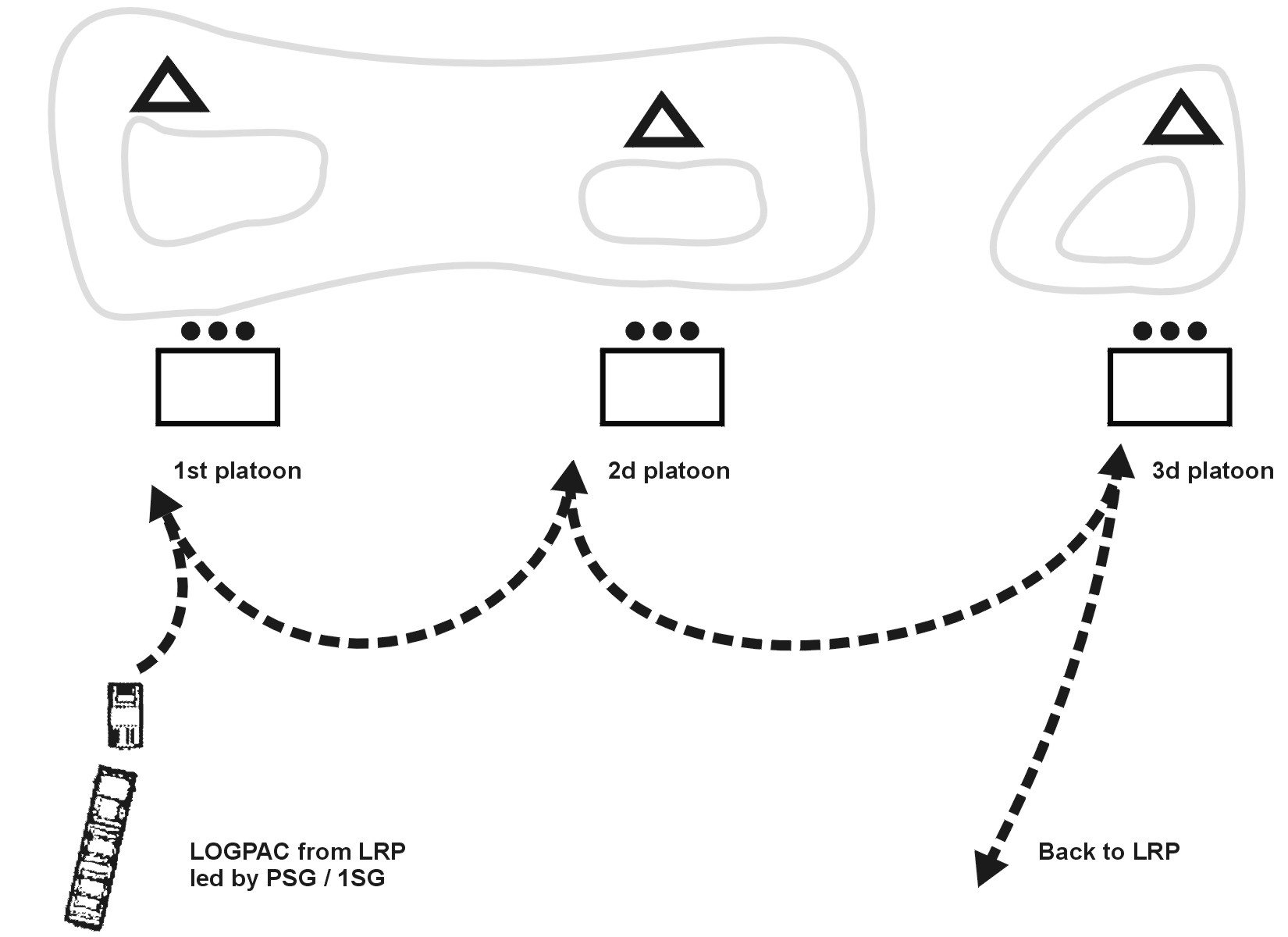

a. Logistics Package Operations. The LOGPAC technique is a simple, efficient way to accomplish routine resupply operations. Antiarmor company and battalion SOPs specify the exact composition and execution order of the LOGPAC.

(1) Preparation. The antiarmor company's supply sergeant first compiles and coordinates all the company's supply requests. Based on the requests, he then assembles the LOGPAC under the supervision of the support platoon leader or the HHC commander. The LOGPAC focuses on the needs of the antiarmor company:

|

When LOGPAC preparations are complete, the supply sergeant initiates tactical movement to the logistic release point (LRP) under the supervision of the battalion support platoon leader. The supply sergeant and LOGPAC linkup with the 1SG at the LRP.

(2) Actions at the LRP. When the antiarmor company 1SG arrives at the LRP to pick up the company LOGPAC, he updates all personnel and logistical reports and is briefed by the support platoon leader or other field trains representatives on any changes to the support situation. He then escorts the company's logistics vehicles to the antiarmor company resupply point, providing security during movement from the LRP.

(3) Resupply Procedures. The antiarmor company can use the service station (out of position) or tailgate (in position) resupply method, both of which are described later in this section. The time required for resupply is an important planning factor. It must be conducted as quickly and efficiently as possible, both to ensure operational effectiveness and to allow the antiarmor company LOGPAC to return to the LRP on time. Service station resupply of the antiarmor company normally can be completed in approximately 90 minutes, but may take longer. Tailgate resupply usually requires significantly more time than service station resupply.

(4) Return to the LRP. Once resupply operations are complete, the LOGPAC vehicles are prepared for the return trip. Antiarmor company vehicles requiring recovery for maintenance or salvage are lined up and prepared for towing. EPWs ride in the cargo trucks and are guarded by walking wounded or other company personnel. All supply requests and personnel action documents are consolidated for forwarding to the field trains, where the appropriate staff section processes them for the next LOGPAC. The 1SG or company supply sergeant leads the company's logistics vehicles back to the LRP, where he links up with the battalion support platoon leader. Whenever possible, the reunited battalion LOGPAC convoy returns to the battalion field trains together. If the company's logistics vehicles arrive too late to rejoin the larger LOGPAC convoy, the vehicles will either move to the battalion combat trains or remain with the company. However, this situation should be avoided.

b. Resupply Methods. As directed by the antiarmor company commander or XO, the 1SG establishes the antiarmor company resupply point using either the service station or tailgate method. He briefs each LOGPAC driver on which method to use. When the resupply point is ready, the 1SG informs the company commander who in turn directs each antiarmor platoon or element to conduct resupply based on the tactical situation.

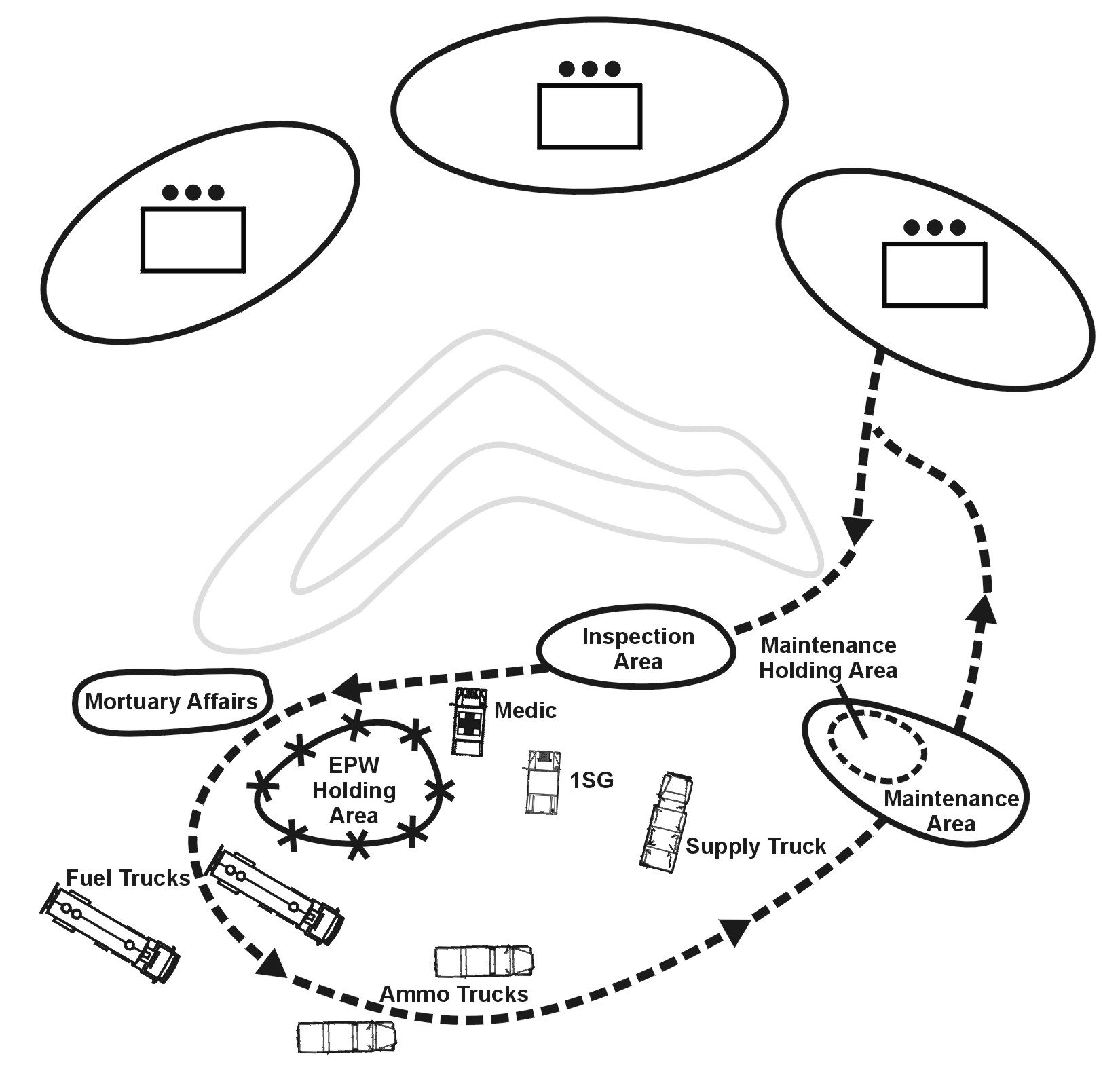

(1) Service Station Resupply. When using the service station method, vehicles move individually or in small groups to a centrally located resupply point. Depending on the tactical situation, one antiarmor squad or an entire antiarmor platoon moves out of its position, conducts resupply operations, and then moves back into position. This process continues until the entire unit has been resupplied (Figure 11-2). In using this method, vehicles enter the resupply point following a one-way traffic flow. Only vehicles requiring immediate maintenance stop at the maintenance holding area. Vehicles move through each supply location, with crews rotating individually to eat, pick up mail and sundries, and refill or exchange water cans. When all platoon vehicles and squads have completed resupply, they move to a holding area where, situation permitting, the antiarmor platoon leader and platoon sergeant conduct a precombat inspection.

Figure 11-2. Service station resupply method.

(2) Tailgate Resupply. The tailgate method (Figure 11-3) is normally used during defensive preparations. Vehicles remain in their positions or back out a short distance to allow trucks carrying supplies to reach them. Buddy-teams rotate through the feeding area, pick up mail and sundries, and fill or exchange water cans. Any EPWs are centralized and guarded.

Figure 11-3. Tailgate resupply method.

11-11. EMERGENCY RESUPPLY

Occasionally (normally during combat operations), the antiarmor company (or platoon) may have such an urgent need for resupply that it cannot wait for a routine LOGPAC. Emergency resupply may involve Classes III, V, and VIII, as well as NBC equipment and, on rare occasions, Class I. The battalion normally uses support platoon and medical assets located in the battalion combat trains to conduct emergency resupply of the antiarmor company. Emergency resupply can be conducted using either the service station or tailgate method, although procedures may have to be adjusted when the antiarmor unit is in contact with the enemy. In the service station method, individual vehicles pull back during a lull in combat on order of the antiarmor company commander (or platoon leader); they conduct resupply and then return to the fight. With tailgate resupply, the antiarmor unit brings limited supplies forward to the closest concealed position behind each vehicle or element.

11-12. PRESTOCK OPERATIONS

Prestock resupply, also known as pre-positioning or cache, is most often required in defensive operations. Normally only Class V items are pre-positioned. Class III supplies can be pre-positioned, but this requires company vehicles to refuel before moving into fighting positions during initial occupation of the BP or to move out of their fighting positions to conduct refueling operations at the rear of the BP. Prestock operations must be carefully planned and executed at every level. All leaders, down to antiarmor squad leaders, must know the exact locations of prestock sites, which they verify during reconnaissance or rehearsals. The antiarmor company must take steps to ensure survivability of the prestock supplies. These measures include digging in prestock positions and selecting covered and concealed positions. The antiarmor company commander must also have a plan to remove or destroy pre-positioned supplies to prevent the enemy from capturing them.

11-13. ANTIARMOR COMPANY RESUPPLY REQUIREMENTS

Company resupply is mainly a "push" system. This means the antiarmor company receives a standard package of supplies from the higher headquarters based on past usage factors and planning estimates. The information-sharing environment provided by FBCB2 (when equipped) reinforces a "push" resupply system.

a. The battalion S4 plans the contents of a LOGPAC. The supplies are normally organized and assembled in the battalion field trains by the antiarmor company supply sergeant under the supervision of the HHC commander and battalion support platoon leader. The LOGPAC should, if possible, provide all supplies, equipment, and personnel needed to sustain the antiarmor company for the next 24 hours or until the next scheduled LOGPAC delivery.

b. Adjustments to the LOGPAC are sent to the battalion S4 (located in the CTCP) via the battalion A/L net, through the antiarmor company supply sergeant, or by a company messenger. When using a battalion A/L net that is not secure, encode reports using the SOI.

c. Company status reports often translate into supply requests, or they provide information to allow the battalion S4 to anticipate antiarmor company needs. An example is the personnel daily summary, which is sent to the battalion S1. It provides the number of personnel in the field, which the battalion S4 can use to plan Class I resupply.

d. The antiarmor supply sergeant is responsible for obtaining supplies and delivering them to the company. He handles small items himself and employs the assets of the support platoon to deliver bulky or high-expenditure items. The antiarmor company commander establishes priorities for delivery, but the demands of combat normally dictate that supplies and equipment in Classes I, III, V, and IX are the most critical to successful antiarmor operations.

Section IV. MAINTENANCE OPERATIONS

The maintenance of weapons and equipment is continuous. Every soldier must know how to maintain his personal weapon and equipment, the antiarmor weapons systems (TOW, M2, and MK19), and the vehicles (HMMWV or ICV). The company commander, XO, 1SG, PSGs, and antiarmor squad leaders must understand maintenance for every piece of equipment in the antiarmor company.

11-14. REQUIREMENTS

Proper maintenance is the key to keeping vehicles, equipment, and other materials in serviceable condition. Maintenance is continuous. It starts with preventive maintenance by the operators and squads, and continues through repairs by maintenance personnel. It includes the services involved in inspecting, testing, servicing, repairing, requisitioning, recovering, and evacuating vehicles and equipment. Personnel should be trained to accomplish necessary maintenance tasks under any condition. Preventive maintenance checks and services (PMCS) on vehicles, weapons, and other equipment should be completed to the standards set in technical manuals and the antiarmor unit's SOP. Maintenance personnel perform repairs as far forward as possible.

a. Antiarmor units in light, airborne, and air assault battalions do not have a maintenance section that operates in their area. These units depend on an austere maintenance section located in the CTCP. The battalion SOP may employ mobile maintenance teams that respond forward to fix damaged vehicles.

b. When maintenance support is needed to repair a vehicle, it is accomplished in the unit's position. If the repairs cannot be completed within a few hours, the vehicle is normally evacuated to the CTCP. The battalion commander makes this decision, and it may mean the vehicle cannot participate in combat operations. This is especially true in the defense, where the loss of an antiarmor weapon system is a major reduction in combat power for the battalion.

c. The unit SOP should detail when maintenance is performed (at least once a day in the field), to what standards, and who inspects it. The antiarmor squad leader is most often the one who inspects maintenance work, with the platoon sergeant, platoon leader, 1SG, XO, as well as the company commander, conducting spot-checks. One technique is for each to spot-check a different antiarmor squad; another is for each to check a single type of weapon or piece of equipment in all antiarmor squads daily. These instructions must be integrated into the unit's SOP for patrol bases, assembly areas, defenses, and reorganization. To ensure maintenance is done without jeopardizing unit security and to make it a habit for the soldiers, clear guidance must be included in the unit SOP.

d. Maintenance applies to all equipment. In addition to operator maintenance, selected soldiers are trained to perform limited maintenance on damaged weapons and to direct exchange (DX) parts from destroyed weapons.

e. Inoperative equipment is fixed as far forward as possible. When a piece of equipment is damaged, it is inspected to see if it can be repaired on location. The company armorer keeps a small-arms repair kit. The battalion communications section has a limited capability to repair FM radios. If equipment cannot be fixed forward, it is evacuated immediately (in an assembly area or defense area), or turned in using the backhaul method when other supplies are brought forward. Even if the item cannot be evacuated at once, the CSS system is alerted to generate a request for a replacement. If a replacement is available (from an evacuated soldier or scavenged equipment), it is sent forward. If not, the leader must work around it by prioritizing the use of remaining equipment.

11-15. COMPANY ROLE IN MAINTENANCE OPERATIONS

Company maintenance functions begin with PMCS, a daily antiarmor squad responsibility, and crew-level preparation of the prescribed maintenance forms (DA Form 2404, 5988-E, or both, as applicable). These forms are the primary means through which the squad obtains repair parts. They follow a pathway, described in the following paragraphs, from crew level to the battalion field trains and back. The antiarmor company 1SG or XO supervises the "flow" of these critical maintenance documents and of repair parts.

a. Antiarmor squad leaders collect their squad's maintenance forms each day. They give the forms to the platoon sergeant, who consolidates them for the platoon. The platoon sergeant, in turn, gives the forms to the company 1SG or XO, who reviews and verifies problems and deficiencies and requisitions Class IX items needed for maintenance and repairs. During the next LOGPAC operation, the completed forms are given to the company supply sergeant at the LRP, who transfers them to maintenance personnel in the battalion field trains.

b. In the battalion field trains, PLL clerks issue the required repair parts they have on hand. They order any other required parts and assign a document number and status for the ordered parts. The maintenance forms, amended with the document numbers and status of ordered parts, are returned to the company supply section (along with the issued repair parts). The amended forms and repair parts are transported via the next LOGPAC to the antiarmor company. The antiarmor squad replaces the defective part.

c. The antiarmor squad conducts initial maintenance, repair, and recovery actions on site. Once it is determined that the squad cannot repair or recover the vehicle or equipment, the platoon sergeant contacts the 1SG. If additional assistance is needed, the 1SG requests it from the battalion.

11-16. DESTRUCTION

When a vehicle or piece of equipment cannot be recovered or is damaged beyond repair, the antiarmor unit leader reports the situation to his higher commander. This commander gives permission for destruction of the materiel if that is the only way to prevent capture of the equipment by the enemy. The antiarmor squad removes all radios, weapon systems, ammunition, personal items, and other serviceable items and parts; it also removes all classified materials or paperwork that could be of intelligence value to the enemy. The antiarmor unit then destroys the vehicle or equipment following unit SOP.

Section V. HEALTH SERVICE SUPPORT

Effective, timely medical care is an essential factor in sustaining the antiarmor company's combat power during continuous operations. The antiarmor company commander must ensure that the company's leaders and its medical personnel know how to keep soldiers healthy, how to save their lives if they are wounded or injured, and how to make them well once injury or illness occurs.

11-17. HEALTH AND HYGIENE

The antiarmor company commander and all leaders, in conjunction with the company senior medic and field sanitation team, must emphasize and enforce high standards of health and hygiene at all times. This "preventive maintenance" approach should cover all aspects of the soldier's health and well being, including the following:

|

11-18. SOLDIERS WOUNDED IN ACTION

Medical treatment of wounded or injured soldiers during combat operations is a continuous, progressive operation that occurs in a series of separate but interlocking stages. It involves personnel, equipment, and facilities at virtually every level of the organization. The normal flow of medical treatment for combat casualties is from the combat lifesaver to the company senior medic at the casualty collection point (CCP) to medics at the BAS. In addition, company leaders play an important role in obtaining and providing medical services for their wounded in action (WIA). The following paragraphs discuss the individual responsibilities of company personnel in this process.

a. Combat Lifesaver. The combat lifesaver is almost always the first person on the scene to begin the process of treating wounded and injured personnel. With the help of buddy aid and of the company aidmen, the combat lifesaver provides initial first aid to WIAs. He prepares them for medical evacuation or returns them to duty status after rendering first aid. Whenever possible, the antiarmor company commander should ensure that there is at least one combat lifesaver assigned to each vehicle.

b. Antiarmor Squad Leader. The squad leader is responsible for ensuring that wounded or injured antiarmor squad members receive immediate first aid and that the company commander is informed of casualties. He coordinates with the platoon sergeant or company senior medic for evacuation (ground or aerial). The squad leader ensures that casualty feeder reports and witness statement forms are completed and routed to the proper channels. (The casualty feeder report stays with the wounded soldier through the CASEVAC process; witness statements are maintained by the 1SG.)

c. Senior Medic. The senior medic is both the company's primary medical treatment practitioner and the supervisor of all battlefield medical operations. The latter role encompasses numerous responsibilities. The senior medic works closely with the antiarmor company commander to ensure all members of the company understand what to do to provide and obtain medical treatment in combat situations. He oversees the training of combat lifesavers and, once combat begins, directs their actions. He assists the antiarmor squad leaders and the 1SG in arranging WIA evacuation. The senior medic is also responsible for monitoring the vital paperwork that is part of the medical treatment and evacuation process:

(1) He ensures that DA Form 1156 (casualty feeder report) remains with each WIA until the soldier reaches a source of definitive medical care (a surgeon or physician's assistant) in the battalion main aid station or field aid station.

(2) If a soldier's remains cannot be recovered, the senior medic ensures that the crew completes DA Form 1155 (witness statement) as quickly as possible and ensures that the form is given to the 1SG for processing.

|

NOTE: |

DA Form 1156 is collected at the aid station by designated medical personnel or members of the battalion S1 section; it is sent to the S1 section for further processing through administrative channels in the battalion field trains. |

d. First Sergeant. The antiarmor company 1SG supervises and coordinates CASEVAC operations, collects witness statements and submits them to the battalion S1, and submits the battle loss report to the battalion main command post, as required. Perhaps his most important duty is managing the company's personnel status during combat operations. As necessary, he directs cross-leveling among platoons and vehicle crews to alleviate personnel shortages. The 1SG also supervises the completion and processing of DA Forms 1155 and 1156.

e. Company Commander. The antiarmor company commander has overall responsibility for medical services. His primary task is to prepare the medical team to treat and evacuate casualties properly. In this role, he works closely with others in the company medical process to ensure that they fully understand the responsibilities described in the previous paragraphs and are proficient in required medical skills. He designates the location for the company's CCP based on a detailed analysis of the factors of METT-TC, and he ensures that all antiarmor squad leaders record the location on appropriate overlays. He also develops and implements appropriate SOPs for CASEVAC. An example is standardized vehicle markings based on the severity of casualties carried on particular vehicles.

11-19. SOLDIERS KILLED IN ACTION

The company commander designates a location for the collection of those killed in action. All personal effects remain with the body, while equipment and issue items become the responsibility of the antiarmor squad leader or section leader until they can be turned over to the 1SG or company supply sergeant. As a rule, KIA remains should not be transported on the same vehicle as wounded soldiers. The company commander sends a letter of condolence to the soldier's next of kin, normally within 48 hours of the death.

11-20. CASUALTY EVACUATION

Effective CASEVAC provides a major increase in the morale of a unit. Casualties are treated where they fall (or under nearby cover and concealment) by a medic, combat lifesaver, or fellow soldier.

a. During the fight, casualties often are left where they received initial treatment (self-aid or buddy-aid). As soon as the situation allows, casualties are moved to the platoon CCP. They then can be evacuated directly to the BAS or to the antiarmor company CCP, which is designated by the antiarmor company commander in the OPORD. The unit SOP should address this activity, to include the marking of casualties during limited visibility operations. Small, standard, or infrared chemical lights work well for this purpose. Once the casualties have been collected, evaluated, and triaged, further evacuation to the battalion CCP or BAS begins. Normally, the BAS is collocated with the battalion CCP.

b. An effective technique, particularly during an attack, is to organize soldiers under the 1SG as a CASEVAC element. These soldiers evacuate casualties to either the company or the battalion CCP, allowing the platoons to continue their fight. The company commander determines the size of the element during his commander's estimate.

c. When the antiarmor company is widely dispersed, the casualties may be evacuated directly from the platoon CCP by vehicle or helicopter. Often, aerial evacuation is restricted by enemy air defense artillery threat. In some cases, the casualties must be moved to the company CCP or battalion CCP before aerial evacuation. When the battalion's organic ambulances are not enough to move the wounded, unit leaders may direct supply vehicles to backhaul casualties to the BAS after supplies are delivered. In other cases, the platoon sergeant may direct platoon litter teams to carry the casualties to the rear.

d. Leaders must minimize the number of soldiers required to evacuate casualties. Casualties with minor wounds can walk or even assist with carrying the more seriously wounded. Soldiers can make field-expedient litters by cutting small trees and putting the poles through the sleeves of buttoned BDU blouses. A travois, or skid, may be used for casualty evacuation. This is a type of litter on which wounded can be strapped, and it can be pulled by one person. A travois can be locally fabricated from durable, rollable plastic on which tie-down straps are fastened. In rough terrain (or on patrols), casualties may be evacuated to the BAS by litter teams, carried with the unit until transportation can reach them, or left at a position and picked up later.

e. Unit SOPs and OPORDs must address casualty evacuation in detail. They should cover the duties and responsibilities of key personnel, the evacuation of chemically contaminated casualties (on separate routes from noncontaminated casualties), and the priority for manning key weapons and positions. They should specify preferred and alternate methods of evacuation and make provisions for retrieving and safeguarding the weapons, ammunition, and equipment of casualties. Slightly wounded personnel are treated and returned to duty by the lowest echelon possible. Platoon aidmen evaluate sick soldiers and either treat or evacuate them as necessary. Remains are kept covered, separated from the wounded, and are evacuated by backhaul on supply vehicles as soon as possible. Casualty evacuation should be rehearsed like any other critical part of an operation.

f. A casualty report, DA Form 1156 (Figure 11-4), is filled out (usually by the squad leader) when a casualty occurs or as soon as the tactical situation permits. The form is turned in to the platoon sergeant who passes it along to the 1SG. A brief description of how the casualty occurred (to include the place, time, and activity being performed) and who or what inflicted the wound is included. If the squad leader does not have personal knowledge of how the casualty occurred, he gets this information from any soldier who does know. Pocketsize witness statements, DA Form 1155 (Figure 11-5), are used to report missing or captured soldiers or when remains are not recovered. The soldier with the most knowledge of the incident completes the form. This information is used to inform the soldier's next of kin and to provide a statistical base for analysis of friendly or enemy tactics. The antiarmor company commander writes a letter to the soldier's next of kin.

|

NOTE: |

Before casualties are evacuated to the company CCP or beyond, leaders should remove all key operational items and equipment, including SOIs, maps, position location devices, and laser pointers. Every antiarmor company unit should establish an SOP for handling the weapons and ammunition of its WIAs. |

g. At the company CCP, the senior medic conducts triage of all casualties, takes the necessary steps to stabilize their condition, and initiates the process of moving them to the rear for further treatment. He assists the 1SG in arranging either ground transport or aerial evacuation.

h. When aerial evacuation is not absolutely necessary or when these assets are not available, the company has these options for transporting casualties:

|

In either option, battalion medical elements assume responsibility for moving WIAs to the BSA for further treatment and evaluation. There, the forward support battalion (FSB) medical company holds them for up to 72 hours. The wounded soldiers are then returned to duty or sent to the rear for additional care.

Figure 11-4. Casualty report.

Figure 11-5. Witness statement.

Section VI. REORGANIZATION AND WEAPONS REPLACEMENT

To maintain effective, consistent combat power, the antiarmor company must have specific plans and procedures that allow each element to quickly integrate replacement personnel and equipment. Unit SOP should define how soldiers and equipment are prepared for combat, including areas such as uploading, load plans, PCCs, PCIs, and in-briefings.

11-21. REPLACEMENT AND CROSS-LEVELING OF PERSONNEL

Replacements for WIA, KIA, or missing in action (MIA) are requested through the battalion S1. Returning or replacement personnel arriving with the LOGPAC should already have been issued all CTA-50 equipment, MOPP gear, and other items, including their personal weapons. Within the antiarmor company, each platoon leader cross-levels personnel among his squads, with the 1SG controlling cross leveling from platoon to platoon. Soldiers from disabled or destroyed vehicles are used to fill out squads until replacement personnel and vehicles arrive at the company CP.

11-22. PERSONNEL REPLACEMENT PROCEDURES

Integrating replacements into an antiarmor company is important. A new arrival on the battlefield may be scared and disoriented as well as unfamiliar with local SOPs and the theater of operations. The following procedures help integrate new arrivals into an antiarmor company:

a. The antiarmor company commander meets all new arrivals and welcomes them to the unit. This is normally a brief interview. The company commander should have an SOP for reception and integration of newly assigned soldiers.

b. The platoon leader and platoon sergeant welcome them to the unit, inform them of unit standards, and introduce them to their antiarmor squad leader.

c. The antiarmor squad leader introduces the new arrivals to the other members of the antiarmor squad and briefs them on their duty positions. He also ensures that each replacement has a serviceable, zeroed personal weapon as well as ammunition, MOPP gear, and other essential equipment. The in-briefing should cover the antiarmor squad and antiarmor platoon's recent and planned activities.

d. The new arrival is told about important SOPs and special information on the assigned vehicle and it's weapon systems as well as information concerning the platoon and squad's area of operations. He may be given a form letter to send to his next of kin. The letter should tell them where to mail letters and packages and how to use the Red Cross in emergencies.

11-23. REPLACEMENT AND SALVAGING OF EQUIPMENT

Lost, damaged, or destroyed equipment is replaced through normal supply channels and brought forward with the LOGPAC. When vehicles are evacuated to the rear for extended periods, crews remove any serviceable equipment or parts for use on other company vehicles.

11-24. WEAPONS SYSTEM REPLACEMENT OPERATIONS

Weapons system replacement operations (WSRO) are conducted to provide units with fully operational, ready-to-fight replacement weapons systems. They cover both vehicle and crew-served systems. The division provides replacement weapons systems to battalions based on brigade priorities. Before these weapons systems are brought forward for delivery to the antiarmor company, the higher headquarters supervises the completion of all necessary PCCs.

Section VII. COMBAT SERVICE SUPPORT IN THE SBCT

The CSS functions within the SBCT are consolidated under the control of the brigade support battalion (BSB). The BSB commander is the SBCT commander's single CSS operator. His staff manages sustaining operations through an array of digital information and automation systems.

11-25. SBCT SUPPORT METHODS

The BSB is designed to perform distribution-based, centralized CSS functions in accordance with Army XXI CSS concepts. The BSB and other CSS elements within the SBCT use a number of support methods to implement these functions. One of those methods is the establishment and maintenance of the logistics preparation of the battlefield. This preparation is the process of gathering data against pertinent battlefield components, analyzing their impact on sustaining operations, and integrating them into tactical planning so that they are synchronized with the decisive and shaping operations. Using this process, the BSB commander must choose from among a number of alternatives to recommend those that best support the SBCT commander's priorities and missions. There are a host of decisions, but two key, interrelated decisions on distribution must be made.

|

The tactical situation will dictate which distribution technique the BSB will use. Each technique offers advantages and disadvantages, and no method is the best alternative in all situations.

a. Supplies are configured in unit sets (battalion/company/platoon depending on the level of distribution) and delivered to one or more central locations. Heavy expanded-mobility tactical truck (HEMTT) fuel tankers remain at the site to refuel unit vehicles as they cycle through the supply point. This technique makes maximum use of the capacity of SBCT truck assets by minimizing delivery and turnaround time.

b. Supply point distribution requires unit representatives to move to a supply point to pick up their supplies. Supply point distribution is most commonly executed by means of an LRP. The LRP may be any place on the ground where unit vehicles return to pick up supplies and then take them forward to their unit. Occasionally, the LRP may be in the BSA.

c. The refuel and or resupply on the move (RROM) method of sustainment operations is conducted in much the same way as the refuel on the move (ROM) concept. The supported unit XO or ISG coordinates with the SBCT S4 and BSB support operations section to establish the time and place to conduct the RROM operations IAW the current situation. As a general rule, an RROM operation is established and conducted as part of a unit movement. An RROM point is typically built to support several types of units passing through the point sequentially and provides for most classes of supply, including Class V and water.

d. Immediate resupply, also referred to as "emergency resupply," is the least preferred method of distribution of supplies. Emergency resupply is an indicator of a breakdown in coordination between the supporting unit and the company. If immediate resupply is necessary, all possible means, including options not covered above, may be used to achieve the necessary supply distribution. It is imperative that constant and thorough planning and collaboration occur between the antiarmor company's XO or supply sergeant and the SBCT S4 and the BSB support operations officer (SPO) to minimize, if not eliminate, the need for immediate resupply. Emergency resupply that extends beyond BSB capabilities requires immediate intervention of the Army forces (ARFOR). In this case, the SBCT S4 and BSB SPO immediately coordinate with the next higher echelon of support for the SBCT.

11-26. FIXING THE FORCE

The BSB provides small combat repair teams (CRTs) from the brigade support company (BSC) to support the infantry battalions, the RSTA squadron, and separate companies. These teams are the first echelon of maintenance for the units. They provide maintenance at the site of breakdown using a limited number of combat spares and battle damage assessment and repair (BDAR) kits. Their objective is to return the combat platform to a mission-capable status quickly using accurate (preferably embedded) diagnostics and limited tools. If they are unable to repair a system, the maneuver unit is responsible for like-vehicle recovery back to the BSA.

a. Once in the BSA, the maintenance control section assesses the vehicle to determine whether it can be returned to a full mission-capable status. If it cannot, the vehicle is placed in a controlled substitution point and stripped of parts to bring other combat platforms to a full mission-capable status. Given the austere organic maintenance capabilities, maintenance of combat unit readiness depends on the use of Class VII.

b. The SBCT has limited ability to perform automotive, armament, missile, communication, power generation, and line replaceable unit repairs. This capability is directly limited by the availability of maintainers and Class IX repair parts. These repairs are achieved by the use of combat spares and controlled substitution in an effort to return the greatest number of systems to a full mission-capable status. Maintenance operates essentially the same way in both the offense and the defense, with the majority of maintenance conducted in the BSA. Units are required to use self-recovery and like-vehicle recovery to the maximum extent possible because of the limited number of wreckers.

11-27. ARMING THE FORCE

The ammunition transfer point (ATP) is located in the BSA or in the vicinity of an airfield. The ATP acts mainly as a temporary distribution point to facilitate rapid Class V resupply to the SBCT. Ammunition is transported to the ATP in mission-configured loads. The ammunition section has limited organic capability to reconfigure loads in the ATP. Units arrive at the ATP to pick up ammunition that is transloaded either into combat platforms or transportation assets. The ATP can also perform rigging for aerial delivery operations if the SBCT has aviation augmentation. The ATP is replenished as required.

11-28. MOVING THE FORCE

The headquarters and distribution company transportation platoon provides transportation support to the SBCT. This support is characterized by a limited, centralized lift capability. The transportation platoon has a 24-hour capability to provide transportation support to the SBCT.

11-29. SUSTAINING THE FORCE

Sustaining the force is the provision of personnel, logistics, combat health support, and other support required to maintain operations or combat until successful accomplishment of the mission. The SBCT operates with extremely austere CSS capability. The primary means of providing supplies to SBCT units is to push pre-configured logistics packages down to company level.

a. Class I. Class I items include subsistence items.

(1) Food. Food supply will consist of MREs only until food service augmentation arrives. MREs are maintained at the BSB and delivered to the company LRPs. Units send vehicles from their operating locations to the supply point to pick up quantities of MREs as needed. Supplements to MREs (fresh fruits, beverages, milk, and so forth) may be provided as available through regional contract sources or air.

(2) Water. The SBCT antiarmor company deploys with three days of supply (DOS) of water. To ensure potability, preventive medicine personnel must inspect water and water sources. The BSB can store 12,000 gallons and distribute 26,000 gallons of water per day. HEMTT-load handling system (HEMTT-LHS) vehicles pulling palletized load system (PLS) trailers distribute water from 500-gallon blivets mounted on the trucks and trailers.

b. Classes II, III (P), and IV. Class II consists of clothing, tools, and individual equipment; limited stocks of Class II items may include preventive medicine and field hygiene items, weapons-cleaning equipment, and special tools. Class III (P) consists of packaged petroleum products; limited Class III (P) includes enough packaged petroleum products to maintain daily operations of vehicles and equipment and to support organizational maintenance. Class IV consists of barrier and construction materials. The BSB maintains a very limited stock of Class IV items, focusing on barrier material and survivability items such as concertina wire, sandbags, and pickets.

c. Class VI. Class VI supplies (personal hygiene, comfort, and welfare items) includes such things as candy, gum, dental care products, soap, and stationery. Initially, the soldier carries these personal items with him. The BSB does not deploy with Class VI to support the SBCT. Class VI items are requisitioned and delivered based on unit demand.

d. Class VII. Class VII supplies (major end-items such as vehicles) are intensively managed and are normally command-controlled. Class VII replacement is based on losses reported through command channels to the SBCT operations officer and logistics officer using an automated reporting system. This permits the commander to maintain awareness of the operational status of subordinate commands and to direct the distribution of items to those units having the most critical need.

e. Class VIII. During deployment, lodgment, and early buildup phases, medical units operate from planned, prescribed loads and from pre-positioned war reserve materiel identified in applicable contingency plans. The SBCT's medical assets deploy with 3 DOS to support a 72-hour self-sustainment mission.

f. Class IX. Class IX (repair parts) includes major assemblies such as engines and transmissions, as well as wheels, tires, batteries, and circuit cards. All repair parts are located in the BSB. The BSB deploys with a limited amount of repair parts (very constrained authorized stockage list), with priority of those parts normally going to command and control systems, combat systems, and then support systems.

11-30. MANNING THE FORCE

The SBCT S1 and augmenting echelon above division (EAD) personnel service support (PSS) units perform all manning functions for the SBCT.

11-31. RESPONSIBILITY OF COMPANY PERSONNEL

The responsibilities of the company personnel are similar to those of the infantry or antiarmor companies in the light, airborne, and air assault battalions. The role the supply sergeant plays in CSS in the SBCT antiarmor company is the significant difference. In addition to his traditional responsibilities of being the company's representative in the BSA, the supply sergeant coordinates directly with the SBCT rear CP or the BSB main CP.

(a) First Sergeant. The 1SG's role as the company CSS executor has changed. He is more a CSS planner and overseer, with his primary responsibility being the senior tactical advisor to the commander on the employment of antiarmor assets. He ensures that the supply sergeant understands the current tactical situation in order to adjust CSS as necessary.

(b) Supply Sergeant. The supply sergeant assists in the assembly of the LOGPAC and moves it forward to the company resupply point. He assists the 1SG with resupply and coordinates the company's CSS requirements with the SBCT S4 or the BSB SPO. The supply sergeant can control the CRT when it is unable to remain forward with the antiarmor company. He monitors the tactical situation and adjusts the company's CSS plan as appropriate to meet the tactical plan and the company commander's intent. He forecasts the company's consumption of the classes of supply based on the operation.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|