CHAPTER 5

EXTERNAL LOADS

Carrying cargo and equipment outside the helicopter eliminates many of the obstacles that other modes of transportation suffer. Helicopters move cargo by external sling load when—

The cargo compartment cannot hold the load.

The load exceeds the helicopter's internal load limitation.

The ground crew must load or unload the cargo at once.

Landing zone conditions prevent the aircraft from touching down.

Pathfinder-qualified soldiers prepare to organize and control external load pickup or drop-off sites as an integral part of LZ operations. The supported unit provides a detailed load plan, to include rough weights and sequences of load movement. This ensures the correct and rapid movement and placement of cargo.

All sling-loading operations use Size 4 or 5 landing points (80- or 100-meter diameter) regardless of the type or size of the helicopter. Area conditions, such as a dusty surface or obstacles, often require pathfinders to increase the minimum spacing between loads. This reduces the number of helicopters that can safely operate at the site at the same time. It also reduces the overall speed of the operation.

All external loads fall into three types: high density, low density, and aerodynamic. Each exhibits unique characteristics in flight. Pathfinders determine the category, size, and weight of the load during the planning phase of the operation.

a. The high-density load offers the best stability

b. The low-density load offers the least stability.

c. The aerodynamic load lacks stability until the airstream stabilizes the load.

Most sling-load operations involve three units. Each has pathfinders who perform specific functions.

a. Supported Unit. The supported unit moves equipment and rigs the loads. Pathfinders in the supported unit check the weight, rigging, and positioning of all external loads to ensure helicopter safety. Ideally, the supported unit provides hookup personnel for individual loads. In the supported unit, pathfinders—

(1) Coordinate in advance with the supporting unit.

(2) Rig the loads.

(3) Furnish slings, straps, clevises, and any other sling-load equipment required for the move.

(4) Check for improper rigging and weight in excess of the aircraft's allowable cargo load.

b. Supporting Unit. This is the aviation unit that will fly the loads.

(1) Provide advice and technical help to the supported unit, as required.

(2) Ensure that the loads fall within the transporting aircraft's ACL.

c. Pathfinder Unit. In the pathfinder unit, pathfinders—

(1) Provide advice and aid to both the supporting and supported units.

(2) Provide expertise in the planning and execution of both pickup zone (PZ) and helicopter landing zone (HLZ) operations.

(3) Supervise the rigging and inspection of all the loads.

(4) Provide ground guidance and air traffic control during the slingload.

(5) Ensure that the loads fall under the transporting aircraft's ACL.

d. Allowable Cargo Load. The ACL depends on the type of aircraft, the age of the airframe, the altitude above sea level, the temperature, the humidity, and the aviation unit's SOP.

Cargo nets and slings make up an essential part of the external load operation. During an inspection, they require the same level of attention that the cargo receives. Any evidence of frayed or cut webbing justifies replacement of the affected component. When they assemble slings, pathfinders should avoid sewing up torn slings or substituting nonstandard parts in the field. Slings must meet the critical strength requirements specified in FM 10-450-3. The Army's inventory includes a variety of equipment adapted or designated for use in sling-load operations.

a. Aerial-Delivery Slings. ADSs were originally designed to deliver heavy loads by air (Table 5-1). They have been adapted for use in air assault operations. ADSs come in a variety of sizes and strengths, as shown in FM 10-450-3, Chapter 6, Table 8-2, and Appendix B.

USAGE |

LOOP |

VERTICAL |

THICKNESSES |

AVAILABLE |

|

Pendant |

2-Loop 1,2 |

8,900 |

4 |

3 Feet |

16 Feet |

9 Feet |

20 Feet |

||||

11 Feet 12 Feet |

120 Feet |

||||

3-Loop |

13,500 |

6 |

60 Feet |

140 Feet |

|

4-Loop |

17,800 |

8 |

3 Feet |

16 Feet |

|

9 Feet |

20 Feet |

||||

11 Feet |

28 Feet |

||||

12 Feet |

|||||

6-Loop |

27,000 |

12 |

60 feet |

120 feet |

|

9-Loop |

42,000 |

||||

Part of |

2-Loop 1,2 |

5,600 |

4 |

3 Feet |

16 Feet |

9 Feet |

20 Feet |

||||

11 Feet |

120 Feet |

||||

3-Loop |

8,500 |

6 |

60 Feet |

140 Feet |

|

4-Loop |

11,200 |

8 |

3 Feet |

16 Feet |

|

9 Feet |

20 Feet |

||||

11 Feet |

28 Feet |

||||

12 Feet |

|||||

6-Loop |

17,000 |

12 |

60 Feet |

120 Feet |

|

|

1 Identified by colored thread stitched lengthwise down the middle of the strap. 2 Three-foot donut ring tensile strength for this sling equals 10,000 pounds. Using dual rings increases tensile strength to 17,500 pounds. |

|||||

Table 5-1. Aerial delivery specifications for the Type XXVI sling.

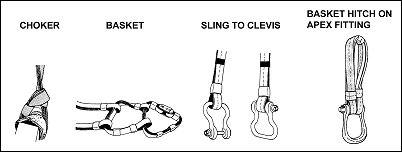

b. Hitches. When connecting ADS to metal air items or directly to the load, loaders use one of the following hitches (Figure 5-1):

Figure 5-1. Hitches.

(1) Choker Hitch. Pull the free-running end of the sling around the point of attachment. Draw it between the loops of the sling's standing end. After making sure that the cotton buffer is in its proper place, "milk" down the keeper on the standing end to secure the sling.

(2) Basket Hitch. Separate the loops of the sling at one end. Place the sling over the suspension point. Ensure that the cotton buffer is in its proper place. To secure the sling, "milk" down the keeper towards the suspension point.

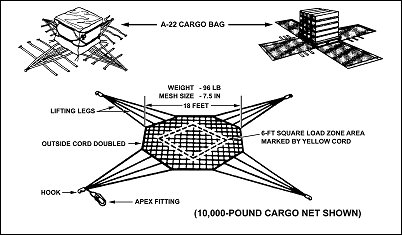

c. Nets and Containers. The Army has many types of cargo containers. However, the 5,000- and 10,000-pound cargo nets and the A-22 cargo bag are the ones most often used to transport cargo externally. Chapter 7, FM 10-450-3 describes how to inspect both the large cargo net and the A-22 cargo bag (Figure 5-2). It also provides rigging instructions. Avoid overloading the nets; use them with loads that fall within the aviation unit's prescribed limits. Pick up the nets rather than dragging them across the ground, since dragging them can cause them to snag on something and damage the net or the thing it snags. Use a canvas insert when carrying items small enough to slip through the netting:

Figure 5-2. Cargo nets and bag.

(1) Small (5,000-Pound Capacity) Cargo Net. This olive drab net can carry up to 5,000 pounds or 125 cubic feet of cargo (NSN 1670-01-058-3811, LIN NO2776).

(2) Large (10,000-Pound Capacity) Cargo Net. This larger net can carry up to 10,000 pounds or 380 cubic feet of cargo (NSN 1670-01-058-3810, LIN NO 2708). It is 18 feet wide and can transport boxed or bulky loads.

(3) A-22 Cargo Bag. The A-22 cargo bag, with or without its canvas cover, can externally transport standard palletized loads, loose cargo, ammunition, oil drums, and other general items whose total weight falls under 2,200 pounds (Figure 5-3).

Figure 5-3. A-22 cargo bag.

(4) Suspension Clevises. Clevises come in three sizes.

(a) Large Suspension Clevis. This clevis (NSN 4030-00-090-5354) has a rated capacity of 12,500 pounds (pendant) with a 7,875-pound sling-to-lifting provision point of attachment. Adding more large clevises as attaching points increases rated capacity as follows:

Two large clevises increase rated capacity to 15,750-pounds.

Three large clevises increase rated capacity to 23,625 pounds.

Four large clevises increase rated capacity to 31,500 pounds.

(b) Medium Suspension Clevis. This clevis (NSN 1670 4030-00-678-8562, Figure 5-4) has a rated capacity of 6,250 pounds (pendant) with a 3,750-pound sling-to-lifting provision. Adding more medium clevises as attaching points increases rated capacity as follows:

Two medium clevises increase rated capacity to 7,500 pounds.

Three medium clevises increase rated capacity to 11,250 pounds.

Four medium clevises increase rated capacity to 15,000 pounds.

Figure 5-4. Upper sling and medium clevis.

(c) Small Suspension Clevis. This clevis (NSN 1670 4030-00-360-0304) has a rated capacity of 6,250 pounds (pendant) with a 3,750-pound sling-to-lifting provision. Adding more small clevises as attaching points increases rated capacity as follows:

Two small clevises increase rated capacity to 7,500 pounds.

Three small clevises increase rated capacity to 11,250 pounds.

Four small clevises increase rated capacity to 15,000 pounds.

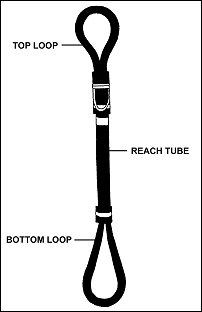

d. Reach Pendants. A reach pendant is a synthetic rope assembly with an attached, stiffened reach tube and a loop on each end. The built-in reach tube enables the hookup man to place the pendant's top eye on the helicopter cargo hook while the helicopter hovers at a higher distance over the load (Figure 5-5). Two reach pendants are authorized for use with slingloads. To use either pendant with a sling set, remove the sling set apex fitting pin; place the pendant's lower eye in the apex fitting; and reinstall the apex fitting pin.

Figure 5-5. Reach pendant.

(1) 11,000-Pound-Capacity Reach Pendant. The 11K, NSN 4020-01-365-3115, part number DSG-5-11K, measures about 5 feet long and has an 11,000-pound safe working load capacity. The top eye is black with a smaller diameter loop, while the bottom eye is green with a larger diameter loop. The safe working load capacity is stamped on the reach tube.

(2) 25,000-Pound-Capacity Reach Pendant. The 25K, NSN 4020-01-337-3185, part number BOS-14-K7, measures about 5 feet long and has a 25,000-pound safe working load capacity. The top eye is black with a smaller diameter loop, while the bottom eye is also black, but has a larger diameter loop. The safe working load capacity is stamped on the reach tube.

CAUTION The older, 25,000-pound capacity reach pendant, issued with an aircraft aerial recovery kit (ARK), P/N 1670EG093-1, is no longer authorized for use in slingload operations. |

(3) Inspection. Inspect the reach pendants before and after use. Check for cuts and tears in the nylon-urethane plastic sheath on each loop. If the white strength member (third layer) shows, remove the pendant from service.

(4) Cleaning. Clean the reach pendant with a mixture of warm water and mild dish or laundry detergent. You can use mineral spirits to remove oil and grease. You can treat the top and bottom eyes with silicone spray. However, do not use silicone spray on the reach tube.

(5) Storage. Store the reach pendants in a clean, dry area out of direct sunlight. Prolonged exposure to sunlight will deteriorate the strength of reach pendants.

CAUTION Avoid getting silicone spray on the reach tube. Avoid using chemical cleaners on reach pendants. Chemicals may weaken the strength members of the pendant. If a pendant becomes contaminated with chemicals, remove it from service. |

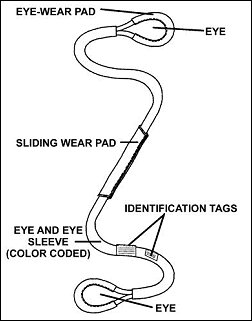

e. Polyester Roundslings. Use polyester roundslings as the primary vertical pendant (Figure 5-6). You can use the three hitches described in Chapter 6 to attach roundslings to the load. The lifting capacity of polyester roundslings varies with the size of the sling and the type of hitch used to attach the load. Each sling has two identification tags permanently sewn to the eye and eye sleeve. These identify the size and capacity of the roundsling as well as other information needed for its safe use. Roundslings are also color-coded by size. Table 5-2 lists roundsling lengths and lift capacities.

Figure 5-6. Polyester roundslings.

PART NO. |

LENGTH |

COLOR |

LIFT CAPACITY |

WEIGHT |

||

CHOKE |

VERTICAL |

BASKET |

||||

PRS2E008 |

8 |

GREEN |

4,200 |

5,300 |

10,600 |

4 |

PRS2E017 |

17 |

GREEN |

4,200 |

5,300 |

10,600 |

10 |

PRS3E008 |

8 |

YELLOW |

6,700 |

8,400 |

16,800 |

5 |

PRS3E017 |

17 |

YELLOW |

6,700 |

8,400 |

16,800 |

11 |

PRS5E030 |

30 |

RED |

10,600 |

13,200 |

26,400 |

26 |

PRS7E065 |

65 |

BLUE |

17,000 |

21,200 |

42,400 |

75 |

PRS7E070 |

70 |

BLUE |

17,000 |

21,200 |

42,400 |

81 |

Table 5-2. Safe working loads (lift capacities) of polyester roundslings.

(1) Storage. Store roundslings in a clean, dry, cool area out of direct sunlight. Prolonged exposure to sunlight will deteriorate the strength of roundslings. (2) Inspection. Inspect each polyester roundsling before and after every use. Remove it from service if you find any of the following:

(a) Missing or unreadable identification tags.

(b) Acid or alkali burns.

(c) Melted, charred, or weld-splattered portions.

(d) Any holes, tears, cuts, snags, embedded particles, broken or worn stitching, or abrasive wear that exposes the core fibers.

(e) Knots in any part of the roundsling.

(f) Distortion, excessive pitting, corrosion, or broken fitting(s).

(g) Any other condition that causes doubt as to the strength of the roundsling.

CAUTION Avoid dragging roundslings on the floor or over rough surfaces. Never twist them or join them together with knots. |

5-5. SERVICE LIFE OF AERIAL-DELIVERY SLINGS

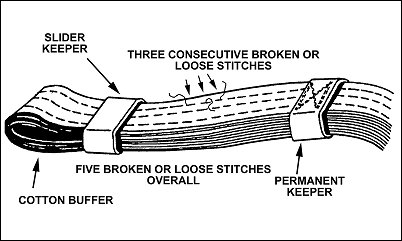

The first person to use a sling must date-stamp it with the calendar or Julian date in 1-inch letters. He can use orange-yellow parachute-marking ink, strata blue parachute-marking ink, or an orange-yellow tube-type marker. He marks near the first keeper at both ends of the sling. This date determines the date of the next inspection. Every six months, the current user reinspects the sling, strikes through the last date in the same color it was written in and, in either of the other two colors, he marks the date he reinspected the sling. For example, if the original user marked the old date in strata blue, the next inspector marks through that date, also using strata blue ink or marker. Then, he uses stencils the current date in orange-yellow, or vice versa. Every single user inspects every single sling before and after every single use. If the condition of the sling seems questionable, he removes the sling from service (Figure 5-7).

Figure 5-7. Unserviceable slings.

a. General Inspection. When inspecting nylon air items, look for any sign of the following. Note that if you find more than three consecutive broken or loose stitches, or five or more broken or loose stitches overall in the sewn portion, the item is unserviceable. After rigging the load with any nylon air item, put cotton buffers in place to prevent any nylon-to-nylon or nylon-to-metal contact:

Inspection date that has already passed (an inspection is overdue).

Foreign matter or chemicals such as mildew, paint, or grease.

Cuts.

Frays.

Burns.

Broken stitches.

Missing cotton buffers, sliding keepers, or permanent keepers.

Rust.

b. Cargo Strap. The A7A cotton or nylon cargo strap measures 188 inches long and has a rated capacity of 500 pounds. A friction adapter located on one end of the strap has a thick-lipped metal floating bar. Supply issues this strap with one metal D-ring. Inspect this piece of equipment for cuts or frays.

c. Cargo Tie-Down Equipment. Check the tie-downs for serviceability.

(1) CGU-1B Tie-Down Strap. The CGU-1B cargo tie-down device has a rated capacity of 5,000 pounds. You can adjust the length of this device.

(2) 15-Foot Tie-Down Strap. The 15-foot cargo tie-down strap, issued with a quick-fit strap fastener, has a rated capacity of 5,000 pounds.

(3) Load Binders. The two load binder types are rated for 10,000 pounds and 5,000 pounds. The 10,000-pound capacity load binder has its rating stamped on the side.

d. Metal Air Items. Sling-load operations commonly require the use of the following metal air items. Thoroughly inspect them for rust, stripped threads on the nuts or bolts, burrs, cracks, bent or twisted metal, or oil. When using any clevis assembly, tighten the nut hand-tight only. Then, tape both ends of the nut and bolt assembly to prevent slippage during use. Use only case-hardened nuts and bolts--never mix items. The bolt heads have case-hardened marks such as ticks, numbers, letters, or a combination of all three:

(1) Inspection. Use the Type IV link assembly (NSN 1670-00-783-5988) to build a 3-foot donut or to connect one ADS to another (Figure 5-8). This link assembly has a rated capacity of 12,500 pounds. When inspecting the Type IV link assembly, look for the following deficiencies:

Hard to rotate or irregularly rotating aluminum buffers.

Bent or cracked posts.

Bent slide connectors.

The absence of a metallic "click" when it locks.

Figure 5-8. Three-foot apex (donut) ring.

(2) Points of Attachment. In sling-load operations, the clevis assemblies serve as points of attachment from the aircraft to the load.

(3) Tightening. When using any clevis assembly, tighten the nut by hand only. Tape both ends of the nut and bolt to prevent slippage during use. Choose only case-hardened nuts and bolts. Never mix items. Case-hardened marks include ticks, numbers, and letters. They will be located on the bolt head.

e. Large-Capacity Sling Sets. The new 10,000-pound and 25,000-pound capacity sling sets are similar, except for a few minor differences. All components have identifying marks. You may only exchange apex fittings between sets. Take care not to mix up the other components. Table 5-3 compares these two large-capacity sling sets. Figure 5-9 shows one.

|

TYPE SLING: |

10,000-POUND SLING |

25,000-POUND SLING |

|

|

CAPACITY: |

10,000 POUNDS |

25,000 POUNDS |

|

APEX FITTING |

COLOR: |

BRUSHED ALUMINUM |

GOLD STEEL |

PIN DIAMETER: |

1 1/8-INCH DIAMETER |

1 1/2-INCH DIAMETER |

|

WEIGHT: |

4 1/2 POUNDS |

10 POUNDS |

|

SLING ROPE |

COLOR: |

OLIVE DRAB |

BLACK |

LENGTH: |

12 FEET |

12 FEET |

|

DIAMETER: |

7/8 INCH |

1 1/4 INCH |

|

|

CHAIN LINKS-QUANTITY: |

110 to 115 LINKS |

86 TO 88 LINKS |

|

|

NSN: |

1670-01-027-2902 |

1670-01-027-2900 |

|

|

TOTAL WEIGHT: |

52 POUNDS |

114 POUNDS |

|

Table 5-3. Large-capacity sling sets.

Figure 5-9. 25,000-pound capacity sling set.

CAUTION Each sling set has four legs. Each leg has a rated capacity of one-quarter of the total capacity of the set. On some loads, you will use up to six legs. However, remember that adding two legs does not increase the rated capacity of the entire set. |

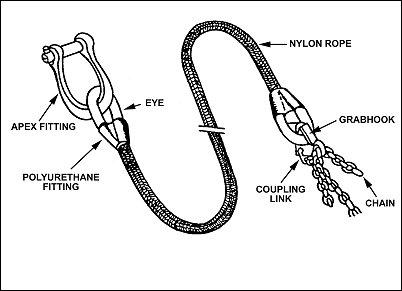

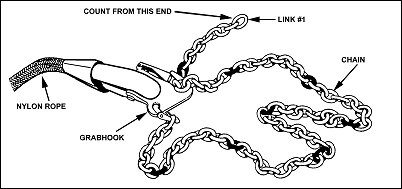

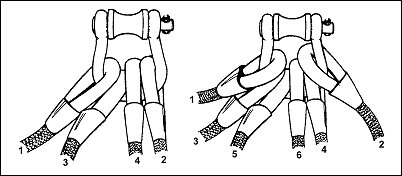

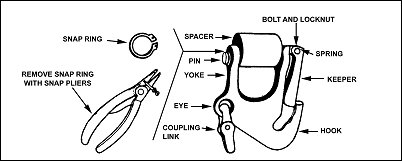

(1) The nylon rope assembly for each set has an interwoven eye located at each end. A polyurethane fitting covers the eye to protect the leg from abrasion and ultraviolet radiation (Figure 5-9). Each double-braided rope connects to a grabhook assembly. Figure 5-10, Figure 5-11, and Figure 5-12 show a coupling link, sling leg-numbering sequence, and a grabhook, respectively. Though the grabhooks for the two sets look alike, you cannot interchange them, because they have different ratings.

Figure 5-10. Coupling link.

Figure 5-11. Sling leg-numbering sequence.

Figure 5-12. Grabhook.

(2) Chapter 6, FM 10-450-3 discusses how to inspect the rope sling sets. Appendix C, FM 10-450-3 provides sling-conversion tables.

(3) Secure the cross pin on each apex fitting with a 3/8-inch bolt, a castellated nut, and a cotter pin. Secure the dome-shaped nut to the apex wrench-tight.

5-6. AIRCRAFT LOAD LIMITATIONS

The structural strength of the cargo hook assembly determines the maximum weight that any aircraft can carry with an external slingload. In most cases, the tensile strength of the hook does not limit the weight that an aircraft can lift--the allowable cargo load does. In fact, the capacity of the cargo hook assembly usually exceeds the ACL.

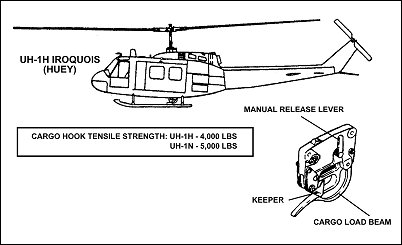

a. Tensile Strength. Cargo hook tensile strengths for US Army aircraft show—

(1) UH-1H/UH-1N Iroquois-4,000 or 5,000 pounds. See Figure 5-13.

Figure 5-13. UH-1H Iroquois and its cargo hook.

(2) UH-60A/60L Black Hawks-8,000 or 9,000 pounds. See Figure 5-14.

Figure 5-14. UH-60 Black Hawk and its cargo hooks.

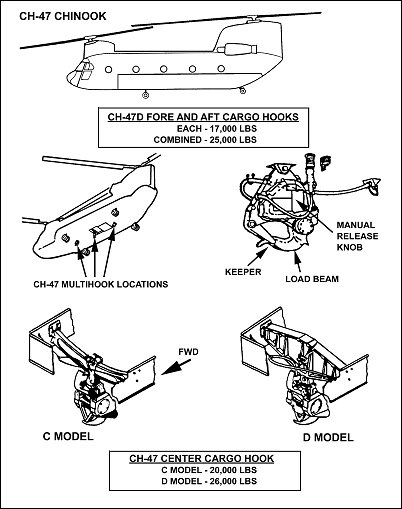

(3) CH-47C/D Chinooks-20,000 or 26,000 pounds. See Figure 5-15.

Figure 5-15. CH-47 Chinook and its cargo hooks.

b. Capacities. CH-47D's fore and aft cargo hooks can each lift 17,000 pounds; together, they can lift 25,000 pounds. The CH-47C's center cargo hook can lift 20,000 pounds. The CH-47D's center cargo hook can lift 26,000 pounds.

c. UH-1H. When transporting external loads with an UH-1H, use a nylon donut or web ring to attach the load to the aircraft. The cargo hook on the UH-1H is stationary; using an apex with a heavy load would bind the hook and shear it off. The cargo hook tensile strengths for the UH-1H is 4,000 pounds; for the UH-1N, it is 5,000 pounds.

d. UH-60 Black Hawk. When using the 10,000-pound apex to secure an external load to the UH-60, you must also use the spacer. When you use the 25,000-pound apex, you must also manually operate the cargo hook. Never use a donut or web ring on an UH-60. The web ring will bind on the hook and prevent the crew from releasing the load in an emergency. The tensile strength of the UH-60 cargo hook system is, for the UH-60A, 8,000 pounds; and for the UH-60L, 9,000 pounds.

When using an UH-60 Black Hawk for airlift, coordinate closely with the aviation unit for the ACL. For standard POL weights (for external loads only), see Table 5-4. Standard weights for vehicles and artillery follow:

FUEL |

55-GALLON DRUM |

500-GALLON BLIVET |

Gasoline (MOGAS) |

404 pounds |

3,400 pounds |

Gasoline (JP4/JP8) |

410 pounds |

3,500 pounds |

Diesel fuel |

457 pounds |

3,800 pounds |

Lube oil (30 weight) |

479 pounds |

4,000 pounds |

Table 5-4. POL for external loads only.

a. Vehicles.

(1) M998/M1038 Truck, Cargo, 1 1/4-ton (HMMWV).

-- 5,200 pounds empty.

-- 7,700 pounds loaded.

(2) M966 TOW Missile Carrier (HMMWV).

-- 6,050 pounds empty.

-- 8,200 pounds loaded.

(3) M416 1/4-Ton Trailer.

-- 580 pounds.

(4) M101A2 3/4-Ton Trailer.

-- 1,350 pounds.

(5) M105A2 1 1/2-Ton Trailer.

-- 2,750 pounds.

(6) M35A2 2 1/2-Ton Truck.

-- 12,000 pounds (add 500 pounds if equipped with a winch).

(7) M149 1 1/4-Ton Water Trailer.

-- Empty-2,540 pounds.

-- Full-6,060 pounds.

(8) M149A1 1 1/4-Ton Water Trailer.

-- Empty-2,540 pounds.

-- Full-6,060 pounds.

(9) M149A2 1 1/4-Ton Water Trailer.

-- Empty-2,800 pounds.

-- Full-6,320 pounds.

b. Artillery Equipment.

(1) M101 105-MM Howitzer.

-- 4,600 pounds (add 300 pounds if equipped with shields).

(2) M102 105-MM Howitzer.

-- 3,160 pounds (add 170 pounds for section equipment).

(3) 105-MM Ammunition.

-- 60 pounds (each box).

(4) 105-MM Ammunition.

-- 47 pounds (each carton).

5-8. AIR ITEMS REQUIRED FOR COMMON STANDARD LOADS

Pathfinders require several types of expendable rigging supplies to complete the rigging of the loads discussed in this paragraph. These supplies include 1/4-inch cotton webbing, 1/2-inch diameter rope, Type III nylon cord (550-pound test), pressure-sensitive tape, cellulose wadding or paperboard energy-dissipating material, and canvas or felt padding. Pathfinders should obtain sufficient supplies of these items before rigging the loads. To rig loads with ADSs (aerial delivery slings) and with more than one suspension point, twist the ADS once for each 3 feet of sling length. This reduces vibration in the sling during flight. The nylon and chain multileg sling sets and the 10,000- and 25,000-pound capacity sling sets do not require the twists. FM 10-450-3 discusses preparation and rigging for the following loads in detail:

a. Net. A 10,000-pound-capacity nylon cargo net (18 feet by 18 feet) requires one A7A cargo strap.

b. Perforated Steel Planking. Perforated steel planking (PSP) requires—

Two 16-foot, two or three-loop ADS.

One 3-foot ADS with one Type IV link assembly (for doughnut).

c. Fuel Drums. One or two fabric fuel drums (blivets), each of which contains 500 gallons of fuel and a 10,000-pound-capacity sling set.

d. Concertina Wire. The items required to move this load depend on the amount of concertina wire in the load.

e. Cargo Bag. The A-22 cargo bag consists of—

(1) One A-22 kit.

(2) One A7A cargo strap.

(3) One 8-foot, two- or three-loop ADS.

(4) One 3-foot, two- or three-loop ADS with one Type IV link assembly (for doughnut).

The behavior of an external load in flight can greatly affect the performance of the aircraft carrying it. High drag coefficients reduce airspeed. Therefore, whoever prepares the load must try to reduce the drag of the load on the aircraft. This means that the task takes longer or does not get finished if the allotted time for the task expires. A high drag coefficient can also endanger the aircraft and crew. Because of this, the pilot must "punch" if he thinks that continuing to fly the load could endanger his crew or aircraft. To stabilize a load, the loaders should—

a. Addition of Weight to the Load. The heavier a load, the less air pressure will disturb it. Thus, carrying heavier loads assures greater stability. However, make sure the load does not exceed the rated capacity of the equipment or the ACL of the aircraft.

b. Streamlining of the Load. Long, symmetrical loads fly crosswise to the direction of flight. This causes a lot of drag on the aircraft. Loads tend to stabilize if the CG (center of gravity) is located in the first one-third of the load. Either adjust the load or, if needed, add weight to move the CG toward one end or the other. The heavier end of the load will "seek" the direction of flight and the load will stabilize. The lighter tail end of the load will act just like the fins on a dart.

c. Airspeed of the Aircraft. The least desirable method is to have the aircraft fly slow to try to keep the load from destabilizing. This burns extra fuel and takes more time to do less work. Prepare the loads so that the aircraft can fly safely at speeds of 60 knots or more.

d. Sling Length. Lengthening the slings that attach the load to the aircraft reduces the load's stability in flight. The shorter, the better, as long as the sling measures at least 6 feet long. Also, the more vertical the attached sling, the less stress on those that are more horizontal. Figure 5-16 shows how sling angle affects load stress.

Figure 5-16. Load chart of sling tension at various angles of inclination with a load of 1,000 pounds.

e. Effect of Vertical Sling. A vertical sling carrying 3,000 pounds has 3,000 pounds of stress on it. That means the stress equals the weight of the load.

f. Effect of 45-Degree Sling. A 45-degree sling carrying 3,000 pounds has 4,242 pounds of stress on it. That means the stress equals nearly one-and-a-half times the weight of the load.

g. Effect of 5-Degree Sling. A 5-degree (almost horizontal) sling carrying 3,000 pounds has 34,419 pounds of stress on it. That means the stress equals more than ten times the weight of the load.

5-10. HOOKUP AND RELEASE PROCEDURES

Hooking up a load requires a team effort. The signalman must position the aircraft over the load. He does this so the slingload team can discharge the static electricity and attach the load to the aircraft as quickly and safely as possible. Most of the time, the air crew releases the load. This seldom requires any ground crew except the signalman.

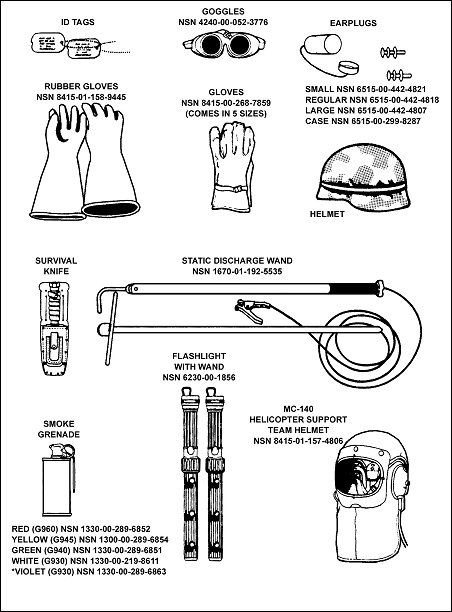

a. Ground Crew Protective Measures and Equipment. Working around hovering helicopters exposes ground crews to a variety of dangers. Leaders must do everything they can to ensure the safety of the ground crews. The crews themselves should use the following safety equipment (Figure 5-17):

Figure 5-17. Protective equipment.

(1) Helmet. This protects the wearer from head injuries caused by flying debris. It also protects him if his head were to get caught between the aircraft and the load, for example. Wearers must keep helmets securely fastened.

(2) Protective Mask or Dust Goggles with Respirator. In high dust or debris environments, each crewmember wears a mask or goggles. This protects the crewmembers' faces, eyes, and respiratory systems from the airborne particles stirred up by the rotor wash. The mask protects better but can cause problems with depth perception (important for signalmen).

(3) Earplugs or Suitable Substitute. These protect against the excessive noise associated with hovering aircraft. They also prevent debris from entering the ear canal.

(4) Hand Protection. Marine Corps and Navy personnel must wear gloves designed to protect electrical workers against burns due to static discharges. Everyone else (USA, USAF, and USCG) should wear leather gloves to help protect the hands and fingers. Whoever must use the static wand to discharge static electricity should wear gloves designed for adequate protection from static discharge burns.

(a) Inspect shockproof gloves before and after each operation. Check for excessive wear, fraying, holes, and tears. Do not use a torn glove. Even a small hole leaves a person unprotected from static electric shock.

(b) Check each glove for holes by filling it with water and squeezing it while holding the open end closed. Or, blow air into it like a balloon and submerge it in water. Any holes will cause air bubbles.

(5) Static Discharge Wand. The static wand protects the hookup man from static electric shock by grounding the cargo hook. In flight, the stored static electric energy of the helicopter increases with its weight, with low humidity, and with the amount of debris blown around by the rotor system (dust, sand, or snow). Thunderstorms can cause huge discharges of static electricity. When the helicopter lands and touches the ground, this charge grounds out. While the helicopter flies or hovers to make a slingload drop, the charge remains stored in the aircraft. As soon as the ground crew member connects the apex fitting to the cargo hook, he provides a path for a charge to follow into the ground. This charge can cause severe electrical burn or injury.

(a) To avoid the possibility of a static electric shock, ground the cargo hook using grounding stakes and static discharge wands (field-expedient and manufactured). Since these wands connect the helicopter to the ground, the static electric charge dissipates. This protects the hookup man from receiving a shock when he connects the apex fitting to the cargo hook.

(b) Inspect the static discharge wand to make sure it is in serviceable condition. Drive the grounding stake opposite the ground crew's exit direction. This keeps them from tripping on the cable as they leave.

(c) Drive the stake into the ground until it seats firmly--at least 6 to 8 inches (firm ground) and 24 inches (sandy or loose soil). Drive the stake in at a 45-degree angle away from the side of the load, in case someone falls on it. Connect the cable clamp to the vertical shaft of the stake.

(d) When operating on concrete or asphalt surfaces, position the loads as close to the edge of the surface as you can. This allows you to drive the grounding stake into the ground.

(e) Do not hold the static discharge wand within 14 to 16 inches of the metal hook end--a strong static charge can jump as far as 12 inches. During the hookup operation, the static discharge wand must stay in contact with the cargo hook. If contact fails, all ground crew members must pull back from the hook until someone can reestablish contact between the wand and the aircraft's cargo hook.

(6) Other Equipment. Use smoke grenades to mark the location of the landing site or to indicate wind direction. Use flashlights with wands to give arm-and-hand signals at night.

b. Safety. In addition to using the proper equipment, soldiers must also follow these other safety measures:

(1) Wear long-sleeved shirts with the sleeves rolled down and fastened. Button your shirt collar. Tuck shirttails or jacket bottoms into your trousers.

(2) Police the operational area thoroughly before conducting sling-load operations. This cuts down on the amount of debris thrown about by rotor wash.

(3) Stay alert during hookup and release operations; sound judgment and common sense hold the keys to success. Stay ready to get clear of the load. Soldiers have been crushed between the aircraft and loads. Some have had loads dragged over them; others took an unwanted ride when they somehow entangled themselves with the load. Whenever you have to make the hookup, take special care. Slings under tension can easily crush an arm or leg against the load. Some of the particular hazards associated with loads include—

(a) Cargo Extensions or Projections. Gun tubes, landing gear, missile launchers, bridge planks, and so forth can interfere with or injure you by striking or tripping you. Stand clear of such projections or position yourself so you can clear the load at once.

(b) Sharp Projections, Hooks, Handles, Racks. If possible, avoid these. Examples include protruding handles or levers such as tarpaulin tie-down hooks, door handles, spare-tire racks, and similar projections. Sharp edges can cause serious injury. You can quickly get hooked to the load if your clothing or equipment catches on something. Keep alert and ready to move out of danger immediately.

(c) Top-Heavy or Narrow-Based Loads. Treat with caution any top-heavy or narrow-based loads that the rotor wash could blow over. If possible, lay this kind of load on its side before starting the hookup. If you cannot do this, position the crew on the side or end of the load that is least likely to tip. Again, stay ready to move away from the danger quickly.

(d) High Loads. High loads can seriously injure you if you climb up on them to hook them up. Rotor wash can sweep you off, or you might have to jump to avoid a dangerous situation. Pay attention to where you stand. Try to stand on a lower projection or step rather than on top of the load. This way, if the aircraft makes contact with the load, it does not catch you in between. Also, try to work from a crouched position or from your hands and knees. Keep solid footholds and handholds, and stay ready to move quickly out of the way, if you need to. If possible, back a vehicle up to the load and use it as a working platform. (Move it out of the way before the aircraft starts to lift the load.)

c. Ground Crew Emergency Conduct. When an aircraft hovering over a slingload suffers an emergency severe enough for the pilot to have to set the aircraft down, he will do so. This can happen all at once such as in a controlled crash. For this reason, whenever an aircraft seems to be having trouble, all members of the ground crew should clear the slingload point by moving to a location coordinated with the aviation unit. Once they have moved far enough away, they should each take a prone position or seek cover until the aircraft lands. Two situations require special note:

(1) Signalman. Face the aircraft; move to a safe spot.

(2) Hookup Men. Try to work along the right side of the load. This way, you do not have to climb over or go around the load to seek safety. You can instead move directly off and away from the load. If the load is a heavy piece of equipment, you might want to keep the load between you and the aircraft while you are moving. This offers you some protection if the aircraft were to crash.

d. Ground Crew Duties. Normally, the ground crew consists of one signalman and two hookup men, with one hookup man acting as static wand man.

(1) Duties of the Signalman.

(a) Before the Aircraft Arrive(s). Direct the positioning of the load. Supervise the inspection of the load for proper routing of the slings and proper preparation. Ensure that the load is ready to fly.

(b) As the Helicopter(s) Approaches. Station yourself 20 meters in front of the load where you can best maintain eye contact with the crew. Give the arm-and-hand signal of "assume guidance." As the helicopter nears the load, use arm-and-hand signals to position the cargo hook directly over the load, close enough that the hookup men can place the apex fitting onto the cargo hook. During this time, position yourself so the pilot can see your signals easily. Since the pilot of an Army aircraft sits on the right side of the aircraft, you will usually stand just to the right of the aircraft. If the terrain forces you to stand somewhere else, make sure the pilot can see you at all times.

(c) During the Hookup Process. Watch the cargo hook and apex fitting. After hookup, the pilot hovers the aircraft until the hookup men clear away from the load. When they have moved clear, you will signal the aircraft upward slowly, so the sling legs gradually take up the load. You must do this to make sure the sling legs clear the load. If the sling legs foul, motion the pilot downward, and then instruct him to cut away the load. If you did a good job of hooking up the load, and if the load suspends properly below the aircraft, then give the aircraft the signal to depart. Then, move quickly aside to clear the helicopter's path.

DANGER AT NO TIME WILL THE SIGNALMAN OR ANY OTHER MEMBER OF THE SLINGLOAD TEAM ALLOW A SUSPENDED LOAD TO PASS OVER HIS HEAD. |

(2) Duties of the Hookup Men.

(a) One of you handles the static discharge wand and the cargo hook. The other controls the apex fitting of the slingload. Together, you must complete the hookup fast to reduce helicopter hover time and to reduce your exposure time under the helicopter.

(b) Position yourselves by the load so that, while the helicopter hovers over the load, you can quickly complete the hookup (Figure 5-18). You must also make sure the signalman can continually observe the operation.

Figure 5-18. Position of hookup team.

(c) When the helicopter moves into the correct position for hookup, whichever one of you is the static wand man must ground the aircraft. Touch the static wand to the cargo hook (Figure 5-19) and keep it there to maintain a continuous ground.

Figure 5-19. Grounding technique.

(d) Once the static wand man grounds the aircraft, the other hookup man places the apex fitting onto the cargo hook, then checks to make sure that the hook is properly closed (and locked, if required).

(e) After you properly hook up the load to the aircraft, both of you must move quickly aside to the location coordinated with the aviation unit. If the signalman learns that any of the legs have fouled, he notifies the pilot at once. Also, you will have to rehook the load.

e. Release Procedures. For this mission, leaders refer to the hookup men as the "cargo release team." As the helicopter approaches the site, the pilot takes instructions from the signalman, who guides the aircraft into position for cargo release. The cargo release team stands by, unless it must release the load manually. The signalman directs the aircraft to set the load on the ground. He gives the release signal. At this time, the apex fitting should fall free of the cargo hook. If it does not, the signalman has the aircraft hover, then he directs the cargo-release team to move under the helicopter and manually release the load from the hook. The load clears the hook. After the release, everyone moves out from under the aircraft. The signalman directs the aircraft to depart and quickly moves out of its path.

(1) If the pilot cannot activate the cargo hook from within the helicopter, and if cargo release personnel open it, then ground crew members must use emergency cargo release procedures: (a) Try to disassemble the doughnut. (b) Pass the ADS through the hook.

(2) If the cargo hook is attached to a clevis or apex fitting, unscrew the nut on the clevis or fitting and remove the pin.

(3) If necessary, derig the load so the aircraft can set down.

f. Hookup Procedures During Whiteouts or Brownouts. The hazards of these conditions (snow or dust) prevent the use of a signalman or a hovering hookup.

(1) Rig the load with a 20-foot or a 40-foot extension (as required) using 20-foot ADS with two or three loops and the appropriate number of Type IV link assemblies. Place an apex fitting at the end of the extension.

(2) Lay the extension to the left of the load. The aircraft approaches normally, then taxis to the location of the apex fitting and stops. Once the aircraft lands, the hookup person moves to the aircraft and attaches the apex fitting to the cargo hook. The aircraft suspends the load and departs as directed by the GTA.

(3) When attaching the extension to skid-equipped helicopters, such as the UH-1H, take care that the sling goes forward of but not through the skid. Then attach it to the cargo hook.

WARNING Before the operation begins, coordinate the ground crew's evacuation route to a rendezvous point. Proper coordination with the liaison officer or helicopter crew prevents confusion. Helicopter emergency procedures depend on terrain, wind direction, and pilot choice. Good coordination prevents the helicopter and ground crews from moving in the same direction. |

5-11. SLINGLOAD INSPECTION RECORD

To improve slingload safety, the Department of the Army implemented inspection procedures for all ARMY equipment moved by the slingload method of air delivery. These procedures went into effect 1 October 1997. All Army loads require inspection by a qualified inspector before the arrival of the supporting aircraft. The inspector completes the Sling Load Inspection Record. (Figure 5-20 shows an example completed DA Form 7382-R. FM 10-450-3.) (Appendix I discusses slingload inspection in greater detail.)

Figure 5-20. Example completed DA Form 7382-R.

a. Inspector Qualifications. Inspectors must hold the grade of E-4 or more. They must also either be a Pathfinder, a certified sling load inspector, or qualified in air assault.

b. Distribution of the Sling Load Inspection Record. Reproduce the slingload inspection record onto 8 1/2 by 11-inch paper, get it through official distribution channels, or downloaded from the AEL. Complete the inspection record in triplicate. Copies of the completed form are distributed as follows:

(1) Give a copy to the supporting aviation unit.

(2) Securely tape or tie a copy to the load.

(3) Give a copy to the supported unit.

|

NEWSLETTER

|

| Join the GlobalSecurity.org mailing list |

|

|

|