|

|

||

| FY99 Annual Report | |||

TEST AND EVALUTION RESOURCES: A BALANCE OF PEOPLE, PROCESSES, AND FACILITIES

INTRODUCTION

Every year, my office reviews the state of test and evaluation in the Department of Defense in accordance with our statutory responsibility to "review and make recommendations to the Secretary of Defense on all budgetary and financial matters relating to operational test and evaluation, including operational test facilities and equipment." This year, we have reviewed the state of test and evaluation more broadly, consistent with our new responsibilities for stewardship of the nation's defense test and evaluation centers.

Again this year, we remain concerned over the Department's ability to meet future T&E requirements given the continuing decline in T&E capability and the deteriorating state of the facilities at our Major Range and Test Facility Base (MRTFB). The Services have been cutting the resources devoted to T&E since FY87. Last year (FY99), MRTFB operating and investment funding was $1.1 billion less than it was in FY90, a 30 percent reduction. During the same period, the Department reduced the MRTFB work force by 11,500 people (26 percent) while T&E workload remained steady. I have argued against such deep reductions because they hurt the T&E community's ability to respond to test requirements driven by dramatic changes in equipment, tactics, and doctrine. T&E is an integral element of the Department's Revolution in Military Affairs and is a partner in the Revolution in Business Affairs as well. Yet we have dramatically reduced our T&E work force and investment and operating programs just as we are being called upon to support the development of more sophisticated, complex, and expensive weapon systems.

People in the Military Departments, Congress, OSD, and Industry realize that T&E has been reduced too much, and are trying to reverse the trend. Especially in the past year, the military departments have sought to increase resources for T&E through the internal DoD processes to formulate the Department's out-year programs. Although these attempts were not completely successful, the fact that they were made at all is a source of encouragement. Another indicator is that the steep declines in some of the T&E resource categories over the past 8 to 10 years have begun to level out. Overall operating funds for the major T&E centers have leveled out, while RDT&E funding for T&E operations have experienced a small increase between FY98-00. Though these positive trends are not enough to recover even a small part of the dramatic losses experienced in recent years, it is encouraging that the declines have stabilized at least in these two categories.

Legitimate concern over the lack of readiness of combat forces and the need for modernization will put continuing pressure on budget resources, and the few positive trends in T&E resources may evaporate. In addition, the trends in other resource areas continue to be troubling. The steady decline in personnel resources over the past 8 to 10 years continues unabated. The projected declines in military personnel are a serious concern. The low rate of investment for the highly complex, costly-to-create T&E facilities, especially in the category of military construction, continues to be a critical problem. The funds to support OT&E are also continuing to decline. In fact, we are very concerned that not enough resources will be available to support OT&E of both major and minor programs. While, in some cases, the picture is not as bleak as in previous years, there continues to be clear evidence of trends that will adversely affect the ability of T&E to support the DoD acquisition process.

Over the past decade, the Department has worked to make its T&E infrastructure more efficient while continuing to provide high quality support. Although we experienced significant reductions in the people and resources needed to maintain and invest in our facilities, we were able to improve our T&E processes to minimize the effects of these reductions. Those improvements enabled us to provide quality T&E support for acquisition programs even with reduced resources. However, we have reached the limit. The deep reductions in people and funding have brought us to a point where few opportunities remain for continued process improvements without new investment.

As we enter the 21st century, the Department faces many challenges that will stress existing T&E resources. To meet these challenges, it is essential that our T&E facilities and operational test agencies have the necessary people, processes, and facilities to adequately test the weapon systems that our soldiers, sailors, airmen, and marines will need.

ASSESSING T&E RESOURCES AS WE ENTER THE 21ST CENTURY

The health of T&E resources (people, processes, and facilities) as the Department enters the 21st century is an essential element in contributing to the Revolution in Military Affairs and the Revolution in Business Affairs. A balanced work force made up of sufficient numbers of people with appropriate skills is the foundation of T&E resources. T&E business processes must build upon this foundation to enable testers to accomplish their mission in an efficient and effective manner. T&E facilities must be modern, efficient, and capable of providing the necessary data to answer crucial questions on system performance, operational effectiveness, suitability and survivability. T&E facilities must be up to the challenge of testing the most advanced weapon systems and components as well as the complexities of testing systems of systems. These components must come together to provide crucial support to the acquisition process.

The T&E community has struggled to offset limitations in manpower and facilities through business process reengineering during the last decade. The T&E work force has done a tremendous job of implementing reengineering initiatives to streamline the test processes through the introduction of labor and time saving devices. These initiatives were made possible by the introduction of technology advances into the test process. However, a decade of reductions and reengineering with limited investment in facilities has brought the T&E community to a point where it can no longer offset limitations by business process reengineering alone.

The positive trend in test resources in FY00 is only a modest step and will not begin to make up for the lack of investment and adequate maintenance and repair at T&E facilities resulting from cuts in the 1980s and 1990s.

The T&E Work Force

Over the last decade, the demographics of the T&E work force have changed¾ this is cause for great concern. T&E depends on its highly skilled, multi-dimensional work force comprised of government civilian, military, and contractor personnel. Further reductions in the T&E work force would be detrimental to the T&E community's ability to provide quality test support. The Department faces an ever increasing challenge to retain a work force with sufficient skill and experience to accomplish the T&E mission since downsizing results in virtually no new hiring while existing positions are eliminated. In addition to the overall reductions in recent years, the Military Departments have dramatically reduced the number of military personnel assigned to T&E functions. This has occurred despite the Department's simultaneous efforts to increase operational realism in testing. The T&E work force is aging¾ a high percentage of the civilian work force is within seven years of retirement¾ and the Department has been constrained in its ability to hire young scientists and engineers as replacements. Furthermore, the skill mix of the T&E work force has not kept pace with advancing technology. Total work force levels alone do not provide insight into the work force challenges facing the T&E community.

Significant Reductions in T&E Work Force

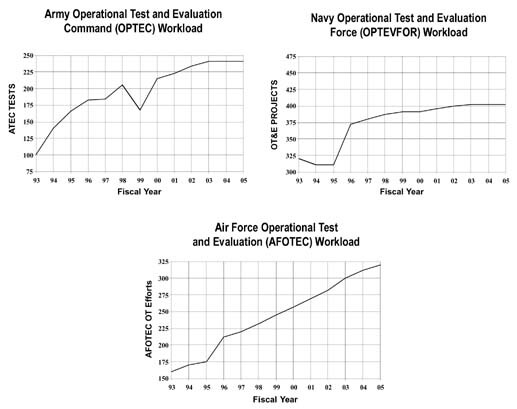

The Service OTA work force, which peaked at 3,500 military and civilian workers in FY93, was reduced to approximately 2,400 in FY99. As Figure 1 illustrates, civilian personnel declined by 484 (30 percent) and military personnel declined by 614 (32 percent) between FY93-99. These reductions significantly exceeded the corresponding decline in the total DoD civilian population (25 percent) and military force (19 percent) during that same period. The reduction occurred despite increases in operational test workload resulting from more complex and intensive operational testing earlier in the acquisition process and an increasing number of non-major and upgrade programs.

Figure 1. Operational Test Agency Workforce Trends

Air Force operational testing workload experienced a dramatic increase of 300 percent from FY92-99 when more than just Major Programs were assigned to the Air Force Operational Test and Evaluation Center. The Air Force is anticipating an additional growth in workload of 50 percent over the next few years to a peak around the year 2003. However, due to the prevailing DoD resource constraints, manpower will increase only modestly over this same period. If all of the projected workload materializes, Air Force operational testers will be limited in the programs they can support. Areas that may see limited involvement by Air Force operational testers could include Advanced Concept Technology Demonstration programs, Battle Laboratory Experiments, and Joint Experimentation programs. This is of particular concern because early operational insights gained from participation in these activities can reduce program risk and acquisition cycle times.

The workload has been increasing at all the Service Operational Test Agencies, and the upward trends are shown in Figure 2.

Figure 2. Operational Test and Evaluation Workload

The Rated (pilot) manning shortfall is another immediate concern that cuts across Air Force organizations, including T&E. These skills are critical to the planning, conduct, and reporting of both DT&E and OT&E. The shortfall affects both staff and line positions. Currently, across the Air Force T&E community, rated positions are manned at less than 60 percent of authorizations. It is expected that the manning level will hover around 55-60 percent well into the next decade. The Air Force is currently developing options to ensure that the quality of T&E does not suffer as a result of the shortfalls. We will keep a close watch on this problem.

Adequate manning at all of our OTAs is imperative if the acquisition process is to benefit from the value of operational perspectives when changes in design, tactics, or doctrine are most easily accomplished. These manpower shortfalls must be addressed to ensure that operational testers can continue to make early, positive contributions.

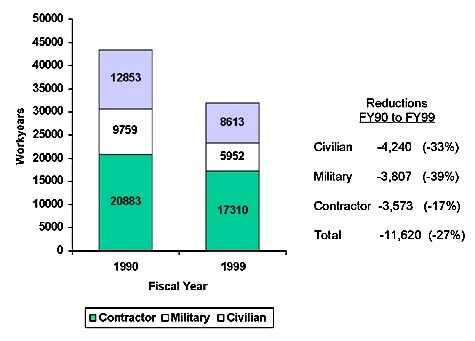

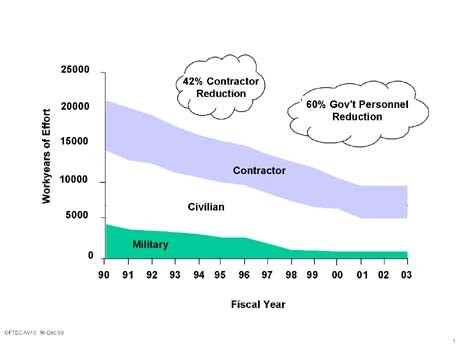

Figure 3. Major Range and Test Facility Base Work Force Trends

The MRTFB work force has also been significantly reduced over the last decade, as Figure 3 illustrates. Between FY90-99, the MTRFB work force was reduced by approximately 11,500 people (26 percent) while workload remained relatively steady. These reductions involved the loss of government civilian, military, and contractor positions. Some of these reductions were made possible by investments in efficiency that allowed facilities to operate with fewer people. One example is the Army's ongoing investments at Kwajalein Missile Range, designed to allow remote control operation of the radars on Roi-Namur and telemetry and optical instrumentation on other islands. When complete, these investments will greatly reduce the number of personnel required on Roi-Namur and other islands and the corresponding logistical support, including the elimination of daily commuter flights. Unfortunately, required investment levels to achieve the predicted $18 million per year savings exceed available funding. The Navy is using key T&E initiatives such as strategic sourcing, pilot programs for laboratories and test centers, and high performance computing to overcome work force reductions. However, some of the overall T&E work force reductions have resulted in a loss of capability at our T&E centers.

Figure 4 illustrates the dramatic decline in the Army's T&E work force over the past ten years. The Army test and evaluation community, now consolidated under the Army Test and Evaluation Command (ATEC), is adapting to manpower reductions of over 50 percent in the government work force and over 40 percent in the contractor work force since the early 1990s. Particularly worrisome is the planned reduction of over 900 positions in FY01 which still must be accommodated in ATEC's Developmental Test Command as part of its share of the Quadrennial Defense Review drawdown. The reductions in Table of Distribution and Allowances-authorized government manning-which have been absorbed by both the Army's operational and developmental test communities far exceed those experienced by the rest of the Army. If workload materializes as expected, some degradation in both Army operational and developmental testing is likely to occur. Priority will have to be given to testing of major systems, so the first instances of impact from the Army's tight budget and manning situation will be on Acquisition Category II, III, and IV programs.

Curtailed Military Participation in Developmental T&E

In an effort to return military personnel to combat units, the military component of the developmental T&E work force has been dramatically reduced. The number of military personnel supporting T&E at MRTFB activities was reduced 39 percent between FY90-99. The Army alone reduced its military personnel directly involved in testing at MRTFB activities by 85 percent during these years. By FY01, the Army will have gone from approximately 760 military people directly supporting T&E at MRTFB activities in FY90 to less than ten¾ a 99 percent reduction. As a result of this drawdown, developmental tests of Army systems are now being routinely conducted without the participation of soldiers. No data is gathered from the ultimate user-the soldier-in these tests. In the past, soldiers participating in testing ensured that a user perspective was integrated early in the development process. In addition, military involvement in testing provided an opportunity for early training and familiarization with new equipment. In an attempt to preserve the military perspective in developmental testing, Army test centers are trying to utilize reserve forces and active duty units from nearby military installations, including those from other Military Services. Although the reductions in the other Services have not been as dramatic, the Navy has reduced its military at MRTFB activities by 25 percent, while the Air Force reduction was 37 percent.

Although the migration of military personnel back to combat units contributes to today's readiness, the loss of military participation in developmental testing will have an unintended and undesirable long-term effect on the ability of T&E to support the acquisition of weapon systems that contribute to tomorrow's readiness. Early participation by military personnel is perhaps the single most important input and key to "weapons that work." Soldiers, sailors, airmen, and marines are key to ensuring an operational perspective during the T&E process. Their knowledge of field conditions and operational requirements put them in a unique position to stress systems under development as they will be stressed in the field.

T&E Work Force is Aging

The T&E community shares the federal government's overall problem of the aging work force. Since FY90, the number of OTA civilian professionals (GS-12 through GS-15) in the 45 to 60 age bracket has increased from just over 50 percent in FY90 to nearly 65 percent in FY98. Civilian professionals under age 45, which had constituted about 45 percent of the professional work force in FY90, now accounts for fewer than 30 percent. Thus, not only are many of the older, more experienced professionals approaching retirement age, but there is concurrently a diminished pool of younger professionals in this work force to succeed them.

Figure 5 shows the composition of the Army Development Test Command work force by age bracket. More than three-fourths of the Development Test Command work force is over the age of 40. This is reason for concern because the older, more experienced component of the T&E work force is leaving at an accelerated rate due to early retirement incentives. The Department's test centers are also losing their youngest employees through resignations and transfers at a much higher rate than predicted. These losses are primarily attributable to job uncertainty-threats of downsizing and contracting out government positions take their toll-and availability of better opportunities in the private sector.

Figure 5: Army Development Test Command Work Force by Age Bracket

While these trends are cause for concern, the problem of an aging work force has been made worse by long-term hiring freezes that have precluded hiring new talent trained in state-of-the-art technology and techniques. For the first time in years, many of our test centers are attempting to hire new workers to fill in gaps left by those leaving. The T&E community is now faced with the challenge of hiring quality scientists and engineers into the T&E work force at a time when the job market is tight and opportunities abound in the private sector.

Work Force Skills Are Not Keeping Pace With Technology

The T&E work force has experienced a gradual degradation of technical skills relative to the leading edge of technology over the past decade. This decline can be attributed to the retirement of the more experienced T&E work force and the extremely limited infusion of recent college graduates trained in state-of-the-art technology and techniques.

The past 25 years have seen not only revolutionary advances in technology and techniques in our weapons systems, but also in the technical capabilities of our ranges and test facilities needed to perform test and evaluation. The T&E work force's skills and knowledge to evaluate and use these new technologies significantly lag these advances. The introduction of the digital battlefield, for example, not only challenges the T&E work force to understand and evaluate complex systems of systems using the latest information technologies, but also challenges the development and use of test capabilities providing the required instrumentation, modeling and simulation, realism of the electromagnetic environment, human behavior and accommodations, and intensive data processing to measure and determine performance and interoperability among all components. Traditional T&E approaches and techniques are no longer sufficient, and a T&E work force capable of testing these systems of systems as they will be deployed, and with the countermeasures that could be deployed against them, requires new skills. Applications of high performance computing, multi-spectrum sensors, distributed data collection and processing, virtual modeling, environmental and terrain simulations, and massive data management are among the challenges facing the T&E work force.

Contractor Work Force Has Also Been Cut

These problems are not limited to our government work force. Our contractor work force has also been significantly cut. Since 1990, over 3,500 contractor jobs have been eliminated at MRTFB activities alone. Our contractors are also facing similar problems retaining and hiring employees. For example, the Atlantic Undersea Test and Evaluation Center has experienced an attrition rate between 20 and 40 percent among its contractor work force in recent years. This attrition rate is in response to pay cuts in order to reduce cost, quality-of-life issues, and long-term career concerns. Generally, a person is offered and accepts a job because there is benefit for both parties. In recent years, the benefit has become lopsided. We are asking people to work, often in remote areas, for less pay than their predecessors on 20- to 30-year-old equipment that is not in use outside a handful of government test centers. When high quality, skilled workers compare this to going to work for a growing company on the leading edge of technology, it is not difficult to understand why we have so much trouble attracting and retaining a quality work force.

Improving the T&E Process

The Department has undertaken an across-the-board effort to reengineer T&E processes to keep pace with Department objectives and advancing technology. Process reengineering efforts have been aimed at two objectives:

- Making the T&E process more efficient by reducing the cost of operations and test facility cycle time to help reduce acquisition cycle time and overall acquisition program cost.

- Introducing new approaches to T&E, such as modeling and simulation, to test advanced technologies where traditional methods are constrained by cost or physical limitations.

Investments Foster Reengineering Efforts

Over the last decade, the Military Services and individual test centers have undertaken a series of initiatives to make the T&E process more efficient and reduce the cost and cycle time for acquisition programs. Many of these initiatives require up-front investment to achieve the desired objectives. The benefit, in terms of reducing T&E operating cost and facility cycle time, is often small compared to the benefit received by the acquisition programs, whose cost and cycle time will also be reduced. Several examples are discussed below.

At the Arnold Engineering Development Center (AEDC) in Tennessee, the Air Force has an ongoing initiative aimed at reengineering its T&E facilities and processes. This activity has applied industry best practices and a disciplined business process reengineering approach that emphasizes cost effectiveness, response, and activity-based costing/management, which is quantified by metrics. This effort has enabled AEDC to provide its test customers enhanced capabilities and services at a lower cost and reduced test cycle time.

The AEDC Propulsion Wind Tunnel sustainment initiative is one example of a facility investment supporting business process reengineering. The propulsion wind tunnel complex at AEDC is comprised of one supersonic and two transonic wind tunnels that provide airflow to simulate conditions found in actual flight maneuvers that test aerodynamic performance of full-scale engines, large aircraft models, and large/full-scale missiles. The modernization of the complex will provide: (1) a new data acquisition and process control system; (2) advanced wind tunnel technology; (3) a new starting and drive motor re-powering network; and (4) a new air dryer. The benefits will include a 50 percent reduction in cost per data point, a 30 percent reduction in lost test time, a significant improvement in tunnel flow quality, and over $1 million per year in energy savings. A seven-year project, costing in excess $80 million, is required to accomplish these goals. The investment will provide large dividends in modernizing and making the complex more efficient.

The Army has also embraced the business process reengineering effort and carefully invested its resources in improving technical efficiency and reducing operating costs. For example, Aberdeen Test Center is currently undertaking a program with the Program Manager of Wolverine (Heavy Assault Bridge) to develop and build a bridge-crossing simulator at Aberdeen Proving Ground. The facility will provide the capability to subject bridging to its service life of crossings at a small fraction of the cost for traditional testing. Instead of using actual wheeled and tracked vehicles to impart repeated loads to the bridge (typically 3,000 crossings), the facility uses an array of hydraulic rams to synthesize full-scale rolling, launch and retrieval, shear, and racking loads. The "per crossing" cost goes from $108 to $5, equating to about $300,000 per durability test. The expected $1.8 million cost of the facility, being shared by the Army's Development Test Command and the Program Manager, will significantly reduce the cost of bridge durability testing and the acquisition costs of Army bridging systems.

Working Together Provides Opportunities for Efficiency and Reduced Cycle Time

Service development and operational test organizations are working together in ways that have contributed to more efficient testing. For example, the B-1B Bomber Block D Upgrade of the Conventional Mission Upgrade Program incorporated a Global Positioning System, a communications package (Very High Frequency/Ultra High Frequency/Satellite Communications radio) and the capability to deliver Joint Direct Attack Munitions (JDAM). A combined DT/OT was conducted at Edwards AFB in California to support the low-rate initial production of the Rotary Launcher modifications, validate upgrades, and prepare for dedicated IOT&E. A total of 20 sorties were performed, accumulating 146 flight hours and 11 JDAM drops (including 8 drops on one sortie). The outcome of the testing was a partial resolution of IOT&E Critical Operational Issues (COIs), successful JDAM weapon scores (combined with later IOT&E scores to determine Circular Error Probable), and a partial resolution of communications COIs. The early look at operational effectiveness and suitability of upgrades reduced flight hours and sorties that would otherwise have been required in IOT&E and identified problems needing resolution prior to IOT&E.

Another example is the Navy's F/A-18E/F Super Hornet program, which leveraged the advantages of combined DT and OT activities. As the first EMD aircraft transitioned from the developing contractor to the Navy at Patuxent River Naval Air Station, MD, it was placed into testing by an Integrated Test Team (ITT). The ITT was made up of test pilots employed by the developing contractor, Navy test pilots assigned to the Naval Air Warfare Center/Aircraft Division (the Navy's developmental test center), and the Operational Test Director from VX-9 (the Navy's agency for conducting operational testing of fixed-wing aircraft). Throughout EMD test flights, contractor pilots and Navy DT/OT pilots actively participated in flights to expand the envelope, verify functional performance, and integrate weapons and stores. Formally and informally, this small group of pilots shared assignments and "lessons learned." All data from all flights were maintained in a common data base that was available for both developmental needs and operational assessments assistance.

The benefits of this close DT and OT coupling were demonstrated as the program discovered and resolved a flight problem referred to as wing drop-when the aircraft makes a sudden, uncommanded roll in certain flight environments. As modifications were installed to counter this phenomenon, the active participation of operational pilots provided feedback as to whether the phenomenon interfered with mission conduct. This synergy between operational insight and developmental effort allowed alternative designs to be quickly evaluated and a production fix determined.

Another major initiative to reduce the cost of testing is to combine testing with training whenever possible. To capitalize on potential synergistic benefits, the test and training communities must work hard to overcome differing objectives, organizational conflicts, and functional differences. Nonetheless, the two communities continue to seek opportunities for partnering their activities. Two successful examples are described below.

- The Marine Corps Program Department (MCPD) performs combat systems assessments and engineering for munitions and ground vehicles. When munitions are redesigned and a prototype round tested, MCPD uses active-duty Marines from neighboring Camp Pendleton, CA, to fire these munitions. This partnership with active-duty units enables MCPD to accomplish its test mission and provides a realistic training opportunity with live munitions.

- The Navy conducts Combat System Ship Qualification Trials (CSSQT) to assist the Commanding Officer of a newly constructed or modernized ship in achieving operational readiness. This is accomplished by conducting tests on the ship's combat systems and logistic support, and by training the crew. The MHC 51-Class Mine Countermeasure Ship OT-IIIB was conducted March 1-16, 1999, during CSSQT. The advantages of conducting OT during CSSQT were: (1) enhanced crew training because test minefields had more targets than normally used in CSSQT; and (2) that combined testing saved approximately 3 weeks of ship operating time.

Working together also helped the Joint Air-to-Surface Standoff Missile (JASSM) program develop an effective solution to attain continuous verification and validation (V&V) of threat models. An Independent Systems Assessment group was formed before the JASSM Milestone II review to coordinate the threat model development process between the JASSM program office, the intelligence community, and the Air Force Operational Test and Evaluation Command. They worked to achieve a balance between the requirements of the acquisition community and the needs of the intelligence community regarding V&V of the threat model. The direct and early involvement of representatives from both the acquisition and intelligence communities ensured that sound V&V practices were followed and that credible threat models were created.

Modeling and Simulation Provides Opportunities for Improving Test Processes

New approaches to testing are needed to reduce acquisition cycle time and test complex new technologies. Modeling and simulation (M&S) has been extensively used in engineering and design efforts to improve product quality. The application of M&S to support T&E is expanding in areas such as facilities and system performance. However, insufficient program resources are being earmarked for T&E modeling and simulation to take full advantage of opportunities.

Where the challenges of assessing system performance are particularly complex, modeling and simulation can be extremely useful. This has proved to be true with constructive simulations and Hardware-in-the-Loop experiments evaluating the performance of systems such as the Theater High-Altitude Area Defense (THAAD) end game algorithms and the Space Based Infrared System sensor performance. For example, physics-based simulations have been developed in conjunction with analyses to model an infrared sensor's missile detection and tracking from space and the end game phase of exoatmospheric engagements.

Another example, White Sands Missile Range's Mission Planning Simulator, NM, utilizes modeling and simulation techniques to allow optics, radar, and telemetry mission planners to visually analyze, rehearse, and optimize mission support plans in a virtual world prior to the live mission. The simulator analyzes target trajectory, camera lens parameters, mount servo performance, microwave radio link parameters, and weather limitations. The Mission Planning Simulator is a general-purpose instrumentation simulator that can be used for any project supported by White Sands Missile Range. A project's plan and site data is easily extracted from the White Sands Resource Management System and inserted into the Mission Planning Simulator. This process allows the simulator to be quickly reconfigured between various project simulations. In the past, flight safety planning for a mission took as much as six staff months to complete, now it takes only hours using High Performance Computers, resulting in significant manpower savings. In addition to savings in mission planning, use of the Mission Planning Simulator provides efficiency improvements in optics operations costs, data reduction, and film processing.

Ranges and Test Facilities

The last of the three principal elements of T&E capability is facilities. T&E facilities must be up to the challenge of testing the most advanced weapon systems and components and providing crucial support to the acquisition process. Responding to the challenges facing the T&E community requires facilities and capabilities that are modern, efficient, cost effective, and capable of providing the necessary data to answer critical questions on overall performance, operational effectiveness, suitability, and survivability. In recent years, not only has the backlog of maintenance and repair at T&E facilities been growing, but investment levels have been insufficient to keep pace with technology and take advantage of improvements in energy efficiency and automation. Additional modernization investments will be required to enable us to accomplish the testing of increasingly complex weapon systems that use highly advanced, integrated technologies.

Figure 6. Major Range and Test Facility Base

Where Testing Occurs

Figure 6 shows the locations of the major DoD test ranges comprising the MRTFB. Training ranges and other support activities are also valuable assets for our test community, especially during operational testing of our weapon systems. Training ranges offer the T&E community a cost-effective opportunity to conduct OT&E under realistic conditions. Training events capitalize on the interplay between users, the unit equipped with the weapon system being tested, and other operational systems. They add a degree of realism that is difficult and costly to achieve otherwise. Employing a system being tested as part of a training exercise also affords operational users early insight into proposed systems and supports the assessment of their value added. However, the majority of the Department's most valuable T&E assets are located at the MRTFB.

The MRTFB, whose primary mission is T&E, is operated and maintained under uniform guidelines to provide T&E support to DoD components responsible for developing or operating defense materiel and weapons systems. The MRTFB is a national asset that is sized, operated, and maintained primarily for DoD T&E support missions, but also available to all users having a valid requirement for its capabilities. The MRTFB was established as an outgrowth of a 1971 Blue Ribbon study which recommended that major T&E assets be organized under defense-wide regulations and have uniform use and funding policies. The policies that exist today are the result of detailed, high-level studies, which determined that these policies were the most optimum to support the acquisition process.

MRTFB Funding Policy

The MRTFB funding policy is designed to ensure the most effective development and testing of materiel, and to provide for inter-Service compatibility, efficiency, and equity without influencing technical testing decisions or inhibiting legitimate and valid testing. The Services and Defense Agencies plan, program, and budget for MRTFB institutional costs and have a reimbursement system that collects user charges for the direct cost of T&E support. Institutional costs are those costs budgeted as part of the Research, Development, Test and Evaluation or the Operation and Maintenance Appropriation, and can be viewed as "keep the door open" costs. This policy has worked well over the years. The users, weapons program managers, pay for all of the T&E support costs under their direct control through reimbursements to the MRTFB. At the same time, the Department pays to have the necessary T&E capability available when needed through institutional funding. Under this approach, users pay a major portion of the operating costs of heavily used facilities. On the other hand, some very complex, expensive-to-operate facilities critical to DoD's T&E capability are less heavily financed by user funds because they are not used as frequently.

Recent congressional legislation requires the Department to study a variety of funding mechanisms for all RDT&E facilities, including T&E facilities. One of the alternative funding mechanisms is a Working Capital Fund (WCF) arrangement. Reviews of these alternatives over the years have determined that they do not work as well as the existing MRTFB funding policy. While not the same as the WCF arrangement in other ways, the existing funding policy is identical to the WCF in its most well known feature-users are charged all of the costs directly attributable to the users workload. The Department's T&E management supports the concept of charging users for cost incurred in direct support of the users, and this concept is consistent with some WCF arrangements within the Department. The current policy satisfies the goals of the major positive attributes of WCF arrangements, such as fostering good business management practices, not encouraging unnecessary use, and providing financial flexibility to handle fluctuating and unpredictable workloads. Transitioning to a WCF would require implementing an entirely new accounting system at most MRTFB activities. It would also require major transfers of funds between programs, the extent of which would depend on how much of the fixed overhead for T&E support would be charged to users.

Based on an initial review, it does not appear that a WCF approach offers any advantages that warrant the disruption that would result from shifting to a new funding approach. A more complete analysis will be provided to Congress as requested.

MRTFB Institutional Funding Significantly Reduced

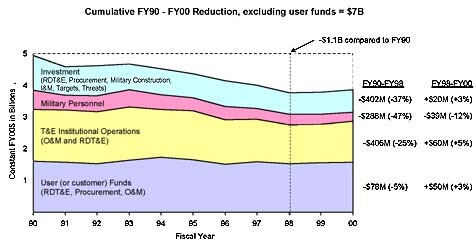

Figure 7 shows that, except for military personnel funding, which continues to drop, MRTFB funding bottomed out in FY98 and experienced a modest recovery in FY99-00. Overall, FY00 MRTFB institutional funding has been reduced 32 percent compared to FY90, a cumulative reduction of $7 billion.

Figure 7. Major Range and Test Facility Base Funding

DOT&E monitors and evaluates the MRTFB to ensure its adequacy to meet requirements and prevent unnecessary duplication of capabilities. Last year, it appeared that funding for Army developmental test support had been reduced to a level that would cause a backlog of work at Army test centers in FY01-02. After much effort on the part of the Army, funding was increased during early phases of this year's programming process to virtually prevent the potential backlog from occurring. Unfortunately, final adjustments to the Army's budget have resulted in the loss of this needed funding and renewal of concern over the Army's ability to support projected test workload. My office will closely monitor the workload for developmental testing within the Army as it evolves to ensure that acquisition programs do not suffer expensive delays.

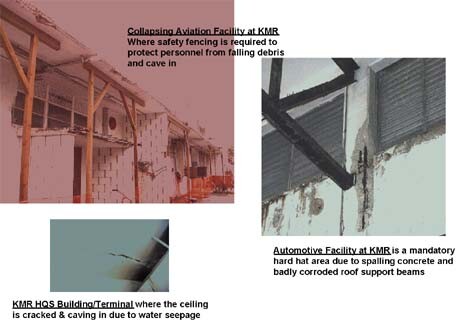

Despite significant resource reductions over the last decade, MRTFB activities have been able to meet test objectives by increasing efficiency, improving processes, delaying maintenance and repair, and minimizing new investments. However, the Department is at a point where additional funding will be required to maintain critical facilities and capabilities. The Army's Kwajalein Missile Range is one example of where additional funding is needed for minimum essential facility sustainment. The pictures in Figure 8 show a few of the significant problems at the Kwajalein Missile Range, for which additional maintenance and repair funding is needed.

The Service and Defense Agencies are required to modernize test support capabilities and replace or repair general-purpose instrumentation, equipment, and facilities. Recent funding trends have placed an enormous burden upon the Services to put off modernization, replacement, and repair of T&E facilities. During the 1999 review of MRTFB activities, most MRTFB activities indicated that T&E facilities are generally in poor shape. Several examples of what was found during the review are discussed below.

Figure 8. Deteriorating Facilities at Kwajalein Missile Range

The Army's Dugway Proving Ground, UT, serves as the Nation's Chemical and Biological Defense Proving Ground to test U.S. and Allied chemical and biological defense systems and perform nuclear, biological, and chemical survivability testing of defense materiel. By FY01, Dugway Proving Ground will have reduced manpower from 581 to 357 and will have to work with a budget reduced from $31 million in FY96 to $23 million. During that time, Dugway's workload will have increased from 442,000 hours to 484,000 hours. Although Dugway Proving Ground has two recently completed new buildings, the Life Sciences Test Facility and the Material Test Facility, the average age of facilities at Dugway is 32.7 years. Many of the buildings at Dugway have fallen into disrepair. Dugway Proving Ground is experiencing problems with its roofs, electrical systems, sewers, and water distribution systems.

The Navy expects business process reengineering to account for 50 percent of the Navy's estimated budget savings of $5 billion across the current Future Years Defense Plan. Despite significant funding reductions, Navy test centers continue to successfully support programs such as the F/A-18, V-22, SH-60, and HARM with a smaller work force and reduced institutional funding. Yet, the Navy also expressed concern over aging and eroding facilities, which is contributing to increased facility maintenance costs and reduced mission capabilities. The average age of facilities at the Naval Air Warfare Center Weapons Division is 46.3 years old. Despite an average annual backlog of maintenance and repair requirement of $63.86 million, the Navy funding for maintenance and repair at MRTFB activities averages only $7.58 million a year.

The Air Force indicated that with increased competition for available funds, they are primarily looking at service life extensions for their T&E support facilities and aircraft rather than improvements to support increased capability. Since FY80, the Air Force's T&E workload at MRTFB activities is up 79 percent, while the T&E institutional funding is down 42 percent. T&E facility modernization and investment in new capabilities are essential if the Air Force is going to continue to meet the challenges associated with advanced technologies and weapon systems. The institutional investment dollars at the Air Force Flight Test Center (AFFTC) in California, $163 million between FY98-01, is considerably smaller than they were in the early 1990s. OSD and customers have invested substantial amounts of money, $103 million, in the test center's facilities. The AFFTC has been able to meet the workload requirements and testing has been successful because of these additional facility investments. As the test support aircraft fleet continues to age, there is considerable concern related to safety, reliability, and supportability. Additionally, frequency encroachment is beginning to have an impact and more schedule delays and potential safety problems are expected. The aging aircraft and frequency encroachment will have a major impact on successful testing if we cannot reverse these trends.

There is growing concern that some important test and evaluation ranges, centers, and assets may not continue to be available to support the Department's T&E requirements in the future. Decreasing Service budgets and changing mission priorities have resulted in instances where critical test capabilities do not have sufficient Service institutional support, investment funding and manpower to support current or future test requirements.

Typical characteristics of these "unique facilities" are often low use and high cost of ownership, but they provide critical, high-value information for decision makers. In a continuing era of budget constraints and changing Service priorities, the owning Service often cannot provide sustainment and investment costs. Some of the critical assets that fall into the "unique facilities" category include:

- Kwajalein Missile Range (KMR) provides strategic and theater missile system testing support and sensor system research and development testing support. Additionally, KMR conducts space object identification, space surveillance, and new foreign launch tracking in support of the U.S. Space Command and NASA. Inadequate funding results in greater deterioration of the facilities at a location where equipment must be replaced more than twice the frequency as other locations due to the extremely corrosive environment. Programs affected include BMD, THAAD, and ICBM testing, as well as space operations.

- Big Crow is an airborne test platform configured as a high power standoff electronic warfare jammer, escort jammer, and self-screening jammer. Required improvements to the platform include increased power capability, enhanced threat fidelity, higher data rates, and increased electronic storage capacity. Programs affected include Patriot Advanced Concepts III, Army Tactical Command and Control System, Joint Surveillance and Target Attack Radar System, Aegis, and E-3A.

- Arnold Engineering and Development Center (AEDC) tests and evaluates aircraft, missile, and space systems and sub-systems at simulated flight conditions. Due to deteriorating facilities, more frequent equipment failures impacting critical development schedules are anticipated. The Air Force has made some investments to address these issues, but additional funds are required. The average annual facility investment is approximately 0.5 percent of the replacement value, which is between 12-25 percent of what is required if we use industry standards. Programs potentially affected include F-22, Joint Strike Fighter, EELV (MDA Delta III), and a variety of engine programs.

- Holloman High Speed Test Track (HHSTT) in New Mexico has many unique capabilities that reduce the programmatic risks of many major acquisition programs. HHSTT can attain test velocities up to Mach 8, is over twice as long as any other test track in the world, and has both the world's largest outdoor rain test capabilities and the world's only adverse attitude aircraft egress test capability. In late FY98 and early FY99, the rail cracked in four places. Three of these failures occurred due to thermal contraction and one failure occurred during a SM-2 warhead sled test. A refurbishment effort is underway; however, additional funds are still required. Programs potentially affected include several BMDO programs, F-22, Navy's Standard Missile II seeker testing, and testing for aircraft egress system developers.

- Keyport North West Range Complex (NWRC) is not a member of the MRTFB but does provide significant test support. The NWRC has the only cold water range and the only range with water depths that allow a broad range of depth testing. User funding can no longer adequately support the NWRC without raising charges to a level that prices the complex out of business. Overhaul and replacement of shore facilities has been postponed. Range craft maintenance and overhauls have been delayed to the maximum allowed, and, in some cases, waivers were obtained to extend the cycle. The NWRC provides an essential test resource that needs to be preserved. Undersea warfare, mine warfare, fleet training, and the Office of Naval Research could potentially be affected.

Due to the necessity of maintaining these "unique facilities," I have initiated an effort to specifically identify test assets not being adequately supported by the owning Service or Agency, and to explore alternatives for management and funding. These alternatives may be necessary to ensure these facilities remain available to support the Department's research, development, acquisition and test requirements. Potential alternatives may include realignment of responsibilities among the Services, supplementary funding provided for specific test capabilities, and outsourcing or partnering with industry.

Investment Is Crucial to Future T&E Capability

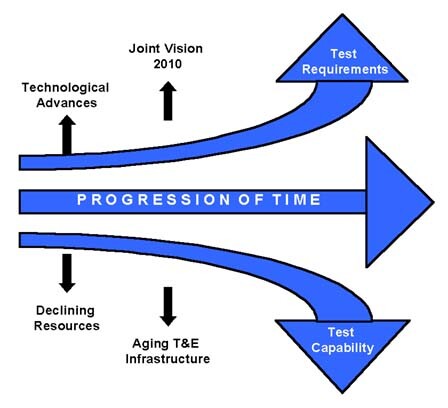

The T&E community faces a significant management dilemma. It must position itself to support Joint Vision 2010 and the Revolutions in Military and Business Affairs despite more than a decade of declining resources and aging and deteriorating T&E capabilities. The question before the T&E community is depicted in Figure 9. How can we bridge the gap between the current state of affairs and where we need to be to support the Department's goals and objectives? We have reached the point where it is imperative that we make a significant investment in test capability modernization.

Figure 9. The Test and Evaluation Management Dilemma: How Do We Bridge the Gap?

Our test capability modernization efforts must focus on three objectives:

- Develop the capability to test the new and increasingly complex technologies to support technology and weapon systems development.

- Re-capitalize outdated and aging T&E facilities and instrumentation.

- Replace inefficient, labor-intensive T&E capabilities with modern, cost-effective capabilities to meet the needs of the 21st century.

We have made some progress toward each of these objectives, but we have a long way to go. Current T&E investment levels hinder our ability to make further strides. A DoD T&E Resources Master Plan is being developed to provide a long-range strategic plan and a business plan incorporating a multi-year investment roadmap. Emphasis will be on increasing cross-Service/Agency reliance and reducing costs of owning and operating the T&E facilities.

Investing In Capability

The importance of investing in T&E capabilities cannot be emphasized enough. Investment in DoD's test capability base is funded through a variety of sources. Each of these sources is briefly discussed below.

- Military Construction Programs¾ except for instrumentation and minor construction, most major T&E capability is acquired through the military construction appropriations. With reduced budgets over the past decade and the need to prioritize against operational force requirements, little military construction funding has been available for T&E facilities except that added to the appropriations by Congress.

- Weapon System Acquisition Programs¾ unique investments to support a specific weapon system are planned and budgeted through the individual acquisition programs. These investments can be made at contractor facilities or at government test centers.

- Service and Defense Agency Investment and Modernization (I&M) Programs¾ designed to provide modernization of existing capabilities and the acquisition of new capabilities to meet individual Service or Defense Agency needs.

- Central Test and Evaluation Investment Program (CTEIP)¾ designed to provide a corporate investment approach to T&E needs, leverage Service and Defense Agency test investments, and fund those joint needs that would be considered beyond the scope of a single Service or Defense Agency. Individual CTEIP investment projects are executed and implemented by the Services and Defense Agencies.

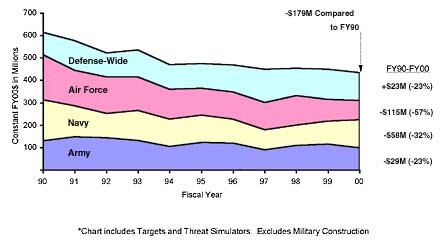

Figure 10. Major Range and Test Facility Base Investment and Modernization

Figure 10 illustrates the trends in Service and Defense Agency I&M and CTEIP T&E investment resources over the last decade. In FY97, investment levels reached a low in the Army, where investment levels were reduced $40 million or 31 percent, and the Navy, where they were reduced $93 million or 51 percent compared to FY90. Air Force investment funding continues to drop. It is down $115 million in FY00 or 57 percent. Defense-wide investment levels have increased somewhat over the last decade.

Current DoD-wide Investment Programs

As part of the Department's actions to improve management of the T&E support base, CTEIP was created and designed to provide a corporate investment approach to T&E needs, leverage Service and Defense Agency test investments, and fund those joint needs that would be considered beyond the scope of a single Service or Defense Agency. This corporate management approach has yielded the following important benefits: testing resources are allocated on the basis of corporate, rather than Service-level benefit; specific areas of commonality such as interconnectivity or improved telemetry techniques can be emphasized for common solutions; and unwarranted redundancies can be minimized. CTEIP's investment approach is tailored to:

- Support projects that apply state-of-the-art technologies to correct shortfalls in the DoD test capability base and improve efficiencies in the testing process.

- Maximize efficient inter-Service use of test assets by improving interoperability and interconnectivity among test centers, ranges, facilities, and areas of T&E expertise.

- Establish and maintain a T&E technology program to investigate, develop, and produce prototypes of advanced technologies that reduce personnel requirements, operating expenses, maintenance requirements, and so on.

- Achieve consistency, commonality, and interoperability across the Services in test instrumentation, targets, and threat simulators.

- Develop, validate, and integrate modeling and simulation with open air testing to provide accurate, timely, and cost-effective results.

- Exploit capabilities in mobile test instrumentation as an alternative to fixed facilities where economically and technically feasible.

- Provide resources to respond to critical near-term operational test capability shortfalls.

To carry out these objectives, the management of CTEIP closely coordinates its activities, including selection of specific projects for funding with the Services' T&E investment planning activities and the Department's Planning, Programming and Budgeting System. The program is structured into three primary categories of projects. The individual CTEIP investment projects are assigned to a lead Service and Defense Agency for execution and implementation. The three CTEIP categories of projects are:

Joint Improvement and Modernization (JIM) projects are those CTEIP investments made to improve the Department's test capability base. They represent critically needed joint test and evaluation investments in the development of test capabilities needed to meet the testing requirements of increasingly complex and sophisticated weapon systems. Projects include automated data collection, processing, display, and archiving; smart munitions testing; simulation and end-game measurement; testing of advanced materials application; test design; and advanced sensors and space systems. A special focus within CTEIP continues to be placed on the potential electronic linking of test ranges and centers to improve test realism, increase testing efficiency, and support joint training. In FY99 there were 24 ongoing major JIM projects. Of this number, two were completed during the year and seven new projects were initiated.

Test Technology Development and Demonstration (TTD&D) projects are intended to facilitate the transition of mature technologies from the laboratory environment into our national test and evaluation centers. Test technology must keep up with or exceed the pace of modern weapons development and increased sophistication. Prime consideration is given to projects that show the potential for high payback in terms of better data for decision making, increased test efficiencies, greater safety, more labor savings, and reduced maintenance costs. Through the TTD&D Project, the T&E community is provided with the equipment and methods from advanced research and development initiatives to test and evaluate new weapons systems. In FY99, fifteen projects were funded. Of these, three were completed and five were new starts.

Resource Enhancement Project (REP) provides quick-reaction, near-term solutions to operational test shortfalls in support of ongoing test programs. REP funding is appropriate when the timeframe from definition of need through critical test dates does not allow for enough time in the budget cycle to fund the required capability. REP subprojects are proposed by the Services and Defense Agencies, reviewed by a panel of Service and Defense Agency representatives, and approved/funded by OSD. All subprojects approved for REP funding are for validated short-term operational test requirements documented in approved operational test plans. The requirements are traceable to a specific weapon system's milestone decision and must meet a critical operational test date within 3 years. In FY99, seventeen projects were funded. Of this number, nine were completed and eight were initiated.

Investment Highlights

Central Test and Evaluation Investment Program

Capability to Test New Technology:

- Advanced Mobile Object Acquisition System will provide DoD's next generation multi-target acquisition and tracking system.

- Advanced Static Radar Cross Section (RCS) Measurement System Upgrade of the outdoor RCS measurement facilities at Holloman AFB, NM, will permit test of next generation of stealth weapon systems.

- Hardened Subminiature Telemetry & Sensor System will provide direct measurements from launch to impact for a wide variety of high-G projectile systems and measure parameters such as attitude, velocities, accelerations, temperatures, pressures, internal processor functions, and sensor functions.

Re-capitalize Outdated T&E Facilities and Instrumentation:

- The Joint Modeling & Simulation System applies the latest High Level Architecture Runtime Infrastructure to model-to-model interactions.

- Joint Installed Systems Test Facility provides a facility able to test a fully integrated aircraft in multi-spectral environments, including targets, threats, and background.

- Replacing inefficient, labor-intensive T&E Capabilities.

- Foundation Initiative 2010 sets guidelines for developing common integrated software tools and processes to improve the capability to configure and re-configure instrumentation resources within the test and training communities.

- Transportable Range Augmentation & Control System develops a self contained, transportable suite of instrumentation to augment developmental/operational flight test and evaluation capabilities at existing DoD ranges and provide capabilities at ranges and/or remote test areas that have little or no basic instrumentation facilities.

Improved Targets and Threat Simulators for Test Realism

The Target Management Initiative program was created within OSD to identify and apply current technology that can improve target threat representation. For example:

- Aerial Target Infrared (IR) Enhancement project will develop an improved IR capability that will meet the needs of the STINGER program.

- Short-Range Air-Launched Target project will provide essential engineering studies and recommendations to resolve IR signature and end point accuracy issues to meet the Navy Area Defense Linebacker Series of flight tests and future THAAD DT testing.

- QF-4 Interoperability will develop a capability to operate the more abundant Air Force version QF-4 on Navy ranges utilizing the current Navy target control system in lieu of using the Navy QF-4 platform.

- Harpoon Seeker on a Target will provide an improved threat representative test and training capability for the NULKA decoy system and the Advanced Integrated Electronic Warfare system.

Efficient Use of Frequency Spectrum

Test and evaluation depends on radio frequency spectrum for the large volume of telemetry, communications, and command and control needed to support almost all test programs. While test program data rates, which directly affect spectrum usage, continue to increase, we have lost access to over 275 megahertz of shared or dedicated spectrum since 1992. Within the next year alone, we will lose 70 percent of one of our critical telemetry bands. This band is crucial to the testing of the Navy's F/A-18 E/F fighter aircraft, a $40 billion program. The remaining part of the band is insufficient to test even one F-18 at a time, and there are requirements for multiple aircraft testing. We can move the F-18 communications to the other telemetry band, but that would affect all of the other test programs assigned to this heavily used band. The F-22 program (a $62 billion program) has similar telemetry band width requirements. There are systems in the pipeline that have equal or greater spectrum needs, including the Joint Strike Fighter ($200 billion program) and ballistic missile defense systems ($56 billion to date plus $12 billion more through FY01 in EMD alone). The ballistic missile defense systems must conduct congressionally mandated multiple simultaneous engagement tests. Each of these tests needs more frequency spectrum than is currently available. The potential consequences of decreased access to this essential but scarce resource include schedule delays and elimination of key tests, which, in turn, result in systems being fielded with uncertain capabilities. This unhappy outcome was clearly demonstrated during operations in Kosovo when an unmanned aerial vehicle experienced severe, mission-crippling self-jamming of its communications links. The system had undergone an accelerated testing program that eliminated the tests that would have caught the deficiency before the vehicle was delivered to the warfighter.

Until recently, there have been no technologies available to allow us to put more data through a given amount of frequency spectrum. Several CTEIP initiatives support our plan for countering the effects of spectrum encroachment. The Advanced Range Telemetry Program is well advanced in the development of a technology that will double the data carrying capacity of our telemetry bands. This same technology will be leveraged by the Flexible Interoperable Transceivers program and the Joint Advanced Missile Instrumentation program to provide similar efficiencies for our target control, scoring, and test support data links. The Multi-Band Antenna Technology program will provide an antenna that allows very small test articles to operate in a number of frequency bands simultaneously. The Advanced High Speed Solid State Recorder project is developing a wide-band data recorder that will provide increased flexibility in on-board storage and selective playback of data, thereby improving the efficiency of band width management.

Proactive stewardship of T&E spectrum resources will continue to guide decisions in the selection and execution of CTEIP programs. The demand for spectrum capacity will continue to increase. At the same time, the T&E community will be seeking new ways of acquiring the data needed to evaluate our weapon systems, and these new methods must confront the issue of limited spectrum resources.

Test Capabilities Needed for Joint Vision 2010

Implementing the weapon systems and concepts in Joint Vision 2010 will depend on a sustained investment to address T&E capability shortfalls and test techniques required for flight, vehicle, sea, and live fire testing. The following paragraphs give examples of needed capabilities that are neither currently fully funded nor available:

Distributed Simulation¾ The ability to learn at the component level is severely hampered when the inputs and effects of the subcomponent on the rest of the system are not available. Advances in distributed simulation have been demonstrated in the Joint Test and Evaluation program, which, if implemented, could accelerate the fielding of new programs. However, linking ranges, laboratories, and factories to achieve this will require a new capability. We must expand the concept of the MRTFB beyond the traditional big acreage ranges and develop inherent linking capabilities at facilities and ranges to ensure on call wide area network access, enhance the interoperability of the MRTFB by use of appropriate M&S standards, and establish distributed testing "centers of excellence." The Joint Surveillance Target Attack Radar System E-8C Block 20 upgrade has just begun the potential leveraging of distributed simulation with the development of Virtual STARS.

Self Defense Test Ship (SDTS)¾ Programs such as the Evolved Sea Sparrow Missile, Advanced Integrated Electronic Warfare System (AIEWS), and Ship Self Defense System (SSDS) use the Self Defense Test Ship to test in operational environments. In the case of AIEWS, a follow-on self-defense test ship will be needed to simulate threat-representative anti-ship cruise missile profiles and conduct safe testing. In addition, since the existing SDTS cannot support installation of an AN/SPS-48E radar, the primary sensor of the LPD-17 combat system, a follow-on test ship capable of being remotely controlled during operationally realistic ship air-defense scenarios, will be required.

Ballistic Missile Defense (BMD)¾ Due to the requirement to effectively kill multiple types of targets and restrictions on realistic operational flight testing, the BMD T&E effort will be complex and rely heavily on ground testing to assess maturity and performance. Although flight-testing produces much more realistic intercept events, the methods for collecting high-fidelity target damage have not been perfected. There is no ground test facility capable of propelling Exoatmospheric Kill Vehicles or their full-scale replicas against targets at the closing velocities expected for National Missile Defense (NMD) intercepts. These closing velocities will exceed 7 km/sec and, in some cases, be closer to 10 km/sec. Existing full-scale sled track facilities have only approached 3 km/sec. The Holloman High Speed Sled Track is working on measures to achieve much higher velocities approaching Mach 10 (about 3.5 km/sec). For higher velocities, light gas gun targets are used because debris from those events can be recovered and examined to evaluate estimates of lethality. For many elements of the BMD system, end-to-end Hardware-in-the Loop simulations must be done at maximum threat loading and high-fidelity scene generation of the end game.

Upgrades of the Army Pulse Radiation Facility at Aberdeen and the Decade X-ray Facility at Arnold Engineering Development Center are urgently needed for National Missile Defense. Together, these two facilities can provide the full threat spectrum for the Exoatmospheric Kill Vehicle and for satellites, which are major elements of NMD. To meet NMD schedules, these upgrades must be accelerated.

Testing and Training in Chemical and Biological Environments¾ The ability to test or train in Chemical and Biological Threat Environments cannot now be simulated adequately.

Methodologies to Integrate Test and Training Activities¾ The complex environments needed to test many new pieces of equipment may be available (at reasonable incremental cost) during the conduct of large-scale training exercises. However, combining testing and training is not easy. The training has an immediate objective to prepare today's force for action if called on immediately. For example, fleet exercises often occur just before fleet deployments. Testing has a longer-range objective to determine whether we should equip a force several years in the future with a new weapon system. These differing objectives have to be carefully considered in combining test and training activities. There has been no systematic study of how to do this well or how to best extract test conclusions from the observation of uncontrolled field training exercises. Test and training activities can mutually benefit from mobile and common instrumentation. Another concept is embedded instrumentation, which could make training easier to conduct as well as automate logistics and maintenance.

C4ISR Interoperability¾ There is also increased attention to interoperability, especially across Service lines. USD(A&T) has recently formed a new office to look at this issue. The future trend in all operational testing will have to reflect the joint nature of military operations. Interoperability testing will have to be conducted in an operational system-of-systems environment with live force-on-force events. This will necessitate having operational assets available to conduct operational testing.

Hypersonics¾ Current hypersonic facilities that allow relatively large-scale components and systems to be tested are few in number, operate primarily below Mach 8, and are only capable of short runtimes. Facilities operating above Mach 8 are more limited, providing only partial simulation that is not suitable for propulsion or aero-thermodynamic testing today. An air-breathing propulsion system for a hypersonic vehicle is a highly integrated part of the airframe with the forward portion of the airframe providing the external compression system for the engine inlet and the aft portion of the airframe serving as the exhaust nozzle. In order to provide a realistic test environment, a ground test facility is required for simulation of the close coupling between the airframe and engine.

Simulation is Key to Improving T&E Capability

Information from instrumented experiments and tests are critical not only to validate future concepts, but also for the high-fidelity simulations required to capitalize on the explosive growth in computer power. Traditionally, test data has simply been treated as part of the customer project, related only to the tests at hand. New technology now makes it possible to support on-line archives that can be integrated into knowledge data bases used both for development of future systems and support of operational systems. The new technology arises from the combination of computational capabilities, dramatic gains in storage technology and costs, high-speed networking, and data mining technology.

Such simulation will require computational simulation environments more powerful than current capabilities at any of the current DoD High Performance Computing Centers. High-performance networking will be the key. Effective test and evaluation requires high performance, innovation-supportive connectivity to other university and industry centers of excellence, the DoD science and technology enterprise, and DoD-wide high performance computing capabilities. This networking must be flexible, reflective of the highest speeds possible, and built on a trusted security model that works in this environment. At this time, the Defense Research and Engineering Network is the only such capability available within DoD.

APPROACHES FOR EVALUATING T&E CAPABILITY

Over the past decade, the major focus of T&E capability analysis has been on "right-sizing." Efforts to "right-size" T&E capability have invariably led to a discussion of capacity and the more pejorative term "excess capacity." Yet, T&E support capacity, particularly excess capacity, is not well understood.

Perceived T&E Excess Capacity

Media and government reports have stated that T&E has significant excess capacity. Quantitative measures quoted regarding excess capacity can all be traced to two study reports: a 1995 Base Realignment and Closure (BRAC) T&E cross-service study and the 1998 Report of the Department of Defense on Base Realignment and Closure. Both of these reports are flawed in their estimates of T&E capacity, which brings into question their conclusions that excess capacity exists.

The 1995 BRAC study assessed capacity for a number of categories of T&E facilities and reported about 50 percent excess capacity for the categories of air vehicles, electronic combat, and armament/weapons testing. The study used the highest workload actually achieved during a historical ten-year period and defined this as the capacity. It contrasted this with a projected severe decline (on the order of 30 percent) in workload. In fact, our current capacity is now significantly reduced compared to the estimates used in the study, while workload has declined only moderately-much less than had been projected in the study. If the study were redone using what we now know about actual capacity and workload, the estimates for over-capacity would likely be quite different-and much lower.

The 1998 BRAC study used metrics appropriate for certain installations that support operating forces but do not fit well when applied to T&E facilities. Estimates for the Army and the Air Force showed excess capacity to be between 24-62 percent. Capacity was not measured but projected to the year 2003 and calculated using an algorithm that determined excess capacity based on square footage of the total facility as a function of acquisition work force and acquisition funding. T&E personnel are part of the acquisition work force and the majority of their funding comes from the acquisition budget. The algorithm results in excess capacity becoming larger as T&E people and funding are cut. This means that T&E managers that reduce capacity by reducing people and funding are actually increasing excess capacity according to this algorithm. Taken to the extreme, this would lead to infinite excess capacity if people and funding were reduced to zero. Clearly this methodology does not work well when applied to T&E facilities.

Test and Evaluation workload is highly unpredictable and variable. It does not make good economic sense to have weapon programs waiting to use test facilities simply to create a high-level workload and high-capacity utilization. A few days delay for a weapon program can result in millions of dollars in increased program cost compared to the relatively low costs to maintain enough test capability to accommodate peak workloads. This is analogous to sizing highways for peak traffic. The capacity of the Washington beltway is fully used at rush hours, but we would not close the outer loop of the beltway to achieve 100 percent capacity all day long.

While the question remains as to how to best define and evaluate T&E support capacity, the above studies do not provide valid measures and conclusions. Ideally, user workload will fund a major portion of the operating cost, and reserve capacity will be at a minimum.

Different Ways to View T&E Capacity

Some view excess or reserve capacity at our T&E ranges as wasteful, but such a view leads to sub-optimization within the total acquisition process. With this approach, the average use of T&E facilities is compared to the maximum potential use if used continuously. T&E facilities exist to support the acquisition process in which the cost of T&E capability is very small compared to the cost of the weapon programs being supported.

Examples of other ways to view utilization abound in everyday life. For instance, public transportation is usually operated at maximum capacity only five days per week during peak rush hours, which would result in 200 percent or more excess capacity if calculated the way some calculate T&E capacity. Such excess is accepted and subsidized because its measure of merit is based on how well the public transportation system satisfies peak loads. Riders simply would not use the system if it were so crowded during times of highest use as to cause significant delays. This would be the result if the system were structured around average ridership (number of passengers per week divided by 168 hours per week). Riders would use automobiles, further straining the road systems and the environment.

Municipal fire departments provide another example. Taxpayers and insurance companies want them nearby and manned around the clock so that response time is short. In almost all service activities and facilities, we encourage reserve, or readiness, capacity and consider it in a positive light because it is part of a larger process or system that is cost effective to optimize.

Some consider the reserve capacity at T&E facilities to be unnecessary capacity. The two are different. T&E workload fluctuates and is unpredictable, so there will always be reserve capacity. However, when users arrive and need access to these same facilities, they would never characterize readiness capacity as unnecessary.

If the cost of maintaining reserve capacity is very high compared to the cost of the consequences of not having it, then the amount of reserve capacity should be held to a minimum. However, in the case of T&E, the cost of not having needed capacity is high when measured against the cost of delays in test programs. Therefore, maintaining some level of reserve T&E capacity is desirable. In general, industry agrees that reductions in cycle time from initial program go-ahead through development and production to delivery to the market is the key to reducing program costs. T&E is part of that process for DoD, and the cost of delays for weapons programs are high. The commercial aircraft industry estimates that delays can cost development programs $10-15 million per day.

Factors in Determining Appropriate T&E Capacity

There are numerous reasons for reserve, or readiness, capacity, which result from the unique requirements of defense T&E. Therefore, the question of excess capacity is one of how much is needed, and not whether it is needed at all. Some of the factors that must be considered in determining appropriate T&E capacity are discussed below.

Maintaining a Diverse T&E Environment¾ Some reserve capacity results from the need to maintain a diverse test environment. For example, if test requirements call for airspace over water, desert landscape, and foliage, then three ranges would be needed. Even though the need for flight test hours could be accommodated on a single range, each of the three ranges would be used a third of the time. Certain test may need to be conducted at a specific time of day, or at sunset, or a specific altitude of terrain; the long list of such requirements is lengthened by the rigorous and varied testing required of military systems. These situations exist throughout the T&E complexes, leading to reserve capacity in order to meet user demands.

Safety¾ The test scenarios demand a rich assortment of activities, many of which can be quite dangerous. Safety considerations may result in large schedule gaps between T&E events to avoid the possibility of people being hurt or expensive equipment being harmed. Weather can exacerbate this problem when conditions occur that would make a test more dangerous (e.g., high wind, rough sea states, low-visibility, etc.). Such considerations are significant factors in why T&E ranges and facilities cannot be used like production lines.

Range Maintenance and Encroachment Issues¾ Numerous environmental issues reduce the availability of T&E ranges such as removal of unexploded ordnance, enhanced protection of endangered species during mating seasons, and noise abatement that preclude use at certain times that add to reserve capacity.

Personnel Policies¾ Certain facilities that see low usage may have a need for reduced hours for certain personnel in order to preclude the maintenance of reserve capacity. However personnel policies preclude asking these employees to work only when they are needed. As a result, capacity may be maintained that is not needed. Union work rules limit the manager's flexibility in this regard, and a host of other personnel policies that maintain fairness for employees can affect reserve capacity.