|

|

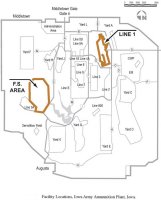

| Click on the small image to view a larger version |

|

|

|

|

|

|

|

|

|

Line 1

|

|

Line 1 is an ammunition production line that has been in operation since the inception of IAAAP in 1941. This Line produces missile warheads and cartridges. This site occupies about 188 acres and includes 106 buildings. These buildings include equipment rooms, explosive magazines, and about 22 buildings for explosive processing. The majority of the contamination occurred as a result of building wash downs and sump failures.

The Atomic Energy Commission operated a portion of Line 1 between 1947 and 1975. Under the purview of the Atomic Energy Commission, the plant was operated by the Mason and Hanger-Silas Mason Company. The Iowa Army Ammunition Plant included a nuclear weapons assembly plant from 1947 to 1975. The IAAP manufactured high-explosive components for nuclear weapons as well as performed the final assembly of the weapons during the years 1949-1975. AEC added numerous facilities within Line 1, but due to the nature of the AEC operations, little information is currently available on past Line 1 activities. It is known, however, that nuclear weapons were assembled at Line 1 using several high explosives and that radioactive materials were "received in a sealed configuration and were swipe tested for leaks before use"

In 1975, work from the Iowa Army Ammunition plant was transferred to the Department of Energy Pantex Plant in Amarillo, Texas.

The Atomic Energy Commission sampled buildings for radionuclides in the 1970's and none were found. Interim Soil ROD identified 266cy of radionuclide-contaminated soil that the Army now believes to be at background levels. In 1999 Senator Tom Harkin convinced the Department of Energy to include the plant in its programs for the nuclear weapons complex and to find, declassify, and release thousands of documents about the plant. He brought the Secretary of Energy to Burlington to listen to the former workers at IAAP and to assure them they could talk about problems at the plant. And he passed legislation to try to change the Pentagon policy that prevents them from even admitting that nuclear weapons work went on at the site.

Since Mason and Hanger-Silas Mason Company no longer exists, there appeared to be no contractor or "willing payer" from which former employees and their families could seek expedited consideration of their claims. By conducting an exhaustive analysis of Mason and Hanger-Silas Mason's contractual relationships in the years following the closing of the Iowa plant, the Department of Energy (DOE) recently determined that BWXT-Pantex should serve as the "willing payer" for the validated Iowa Army Ammunition Plant applications.

|

|

|

|

|

|

|

|

Line 2

|

|

Line 2 is a production line that has been in operation since the inception of IAAAP, except for a brief hiatus from 1947 to 1949 and occupies nearly 140 acres, including 31 buildings and covered walkways. It is used to load, assemble and pack 120mm ammunition. The melt building appears to be where the highest volumes of wastes are produced. The buildings include equipment rooms, explosives magazines and nine sump buildings.

|

|

|

|

|

|

|

|

Line 3

|

|

Line 3 is a production line that has been in operation since 1941, except for a short time between 1945 and 1949. This line fills and assembles artillery projectiles, occupies about 150 acres and consists of 26 buildings and covered walkways. The buildings include equipment rooms, explosives magazines, and nine sump buildings for explosive waste processing. The two melt buildings appear to

be the areas where the highest volumes of wastes were produced during operations. The Interim Soil ROD identified 119cy of radionuclide-contaminated soil that the Army now believes to be at background levels. From 1977 to 1984, metal cleaning operations were conducted at Line 3. This process consisted of several stainless steel dip tanks where ammunition casings were immersed in a sulfuric/hydrochloric acid bath, followed by a chromic acid rinse, then rinsed with water. Sludge that accumulated in the bottom of the sulfuric acid tank was removed, treated with sodium hydroxide, and disposed in the Line 3A Pond (IAAP-041).

|

|

|

|

|

|

|

|

Line 3A

|

|

Line 3A was constructed in 1941 and began operations in 1943. The line was shut down from 1945 to 1949 then resumed operations until 1989. Line 3A encompasses 119 acres and is currently active. The line is a load, assemble and pack operation for 155mm artillery rounds and mortar rounds. The melt building appears be the area where the highest volumes of wastes were produced during operations. Metal cleaning operations were also conducted here from 1977 to 1985. The process included several stainless steel dip tanks where ammunition casings were immersed in a sulfuric/hydrochloric acid bath, followed by a chromic acid bath and water rinsing.

|

|

|

|

Lines 4A and 4B

|

|

Lines 4A and 4B are located in the north-central portion of the plant and are approximately 1000 feet apart. Line 4A encompasses 20 acres and Line 4B encompasses 17 acres. Both lines were constructed in 1941 for component assembly. Line 4A produced detonators and was in operation between 1942 and 1945; it was reopened in 1982. It is currently leased to a private corporation (ICI), who reworked the line to make air-bag initiators, and operations have ceased. There are 12 buildings in the area which consists of an assembly building, mixer buildings, lead azide magazine, detonator service magazine and change houses. Hazardous substances at Line 4A include lead azide, RDX, lead styphnate, tetracene, barium nitrate, TNT, HMX, and metals. Fourteen in-ground sumps (treatment tanks) underwent RCRA closure in 1995. Line 4B is an assembly facility for components manufactured elsewhere. Operations began in 1941 and ceased in 1945. Production resumed in 1962 and the line was used for missile assembly in the late 1960's. Line 4B consists a fuse assembly and equipment building, detonator service magazine, rest houses and change houses. Hazardous substances of concern are TNT, RDX, Composition B, HMX, and LX-14. Previous materials included tetryl, booster pellets and fuze ingredients.

|

|

|

|

Lines 5A and 5B

|

|

Lines 5A and 5B were booster and grenade lines situated in the north-central portion of the installation. Line 5A is about 33 acres and Line 5B is 41 acres. Both lines were constructed in 1941 and operated from 1942 to 1945. Production resumed in 1949 during the

Korean War and intensified in 1961 during the Vietnam War. Line 5A is currently in a lay-away status; there are no plans to activate this line in the future. Line 5A is under the Industrial Preparedness Plan (IPP). Line 5B is being rented by Advanced Environmental Technology (AET) for destructive disposal of ammunition. In the past, both lines were component lines for pelletizing and assembly of explosive components. A testing platform and a firing pit are located within the site boundary. Principle explosives used at these lines were TNT, RDX and Tetryl.

|

|

|

|

|

|

Line 6

|

|

Line 6 is a detonator production area encompassing 30 acres and located in the center of the installation. Constructed in 1941 and operated until 1981, this line is currently inactive. Line 6 consists of 34 buildings for the production, storage, and shipping of detonators, relays, and hand grenade fuses. The primary waste stream was related to the production of detonators and included lead azide, lead styphnate, tetracene, RDX, barium nitrate and mercury fulminate. Treatment of black powder was performed in Building 6-68 as a RCRA permitted unit. This unit underwent RCRA closure in 1995 and will no longer be maintained or used by the Army (modified caretaker status). As part of the RCRA closure, 800cy of contaminated soil was removed in 1994.

|

|

|

|

|

|

Line 7

|

|

Line 7 was a production Line that encompassed 9 acres, built in 1941 and has been inactive since 1970. It was a fuze and blank load, assemble and pack operation where artillery primers, rocket igniters and time fuzes were assembled for World War II and the Korean War. Line 7 and will no longer be maintained or used by the Army (modified caretaker status).

|

|

|

|

Line 8

|

|

Line 8 was a production Line that was constructed in 1941 and was used during World War II to produce Amatol. The Emergency Export Co. utilized the ammonium nitrate crystallization equipment to produce fertilizer to support the Marshall Plan. Subsequent

activities were fuze and rocket igniter load, assemble and pack operations. Prior to closing of the production activities around 1950, Line 8 consisted of four process buildings, a gate house, and tank farm to store ammonium nitrate liquor. Ammunition inspection activities took place from 1976 to 1993. Only two buildings remain and will no longer be maintained or used by the Army (modified caretaker status).

|

|

|

|

Line 9

|

|

Line 9 is about 9 acres in size and was built in 1942 for use as a production facility and produced mine and

mine fuses during the Vietnam War. This Line is in lay-away status.

|

|

|

|

Line 800

|

|

Line 800 is nearly 18 acres in size and has been in operation intermittently since plant inception. From 1943 to present, the primary function of the line was ammunition renovation, where the explosives filler is washed from the projectiles, and 75mm blank salute ammunition was loaded. Wastes were generated by metal cleaning operations at Line 800, which were identical to the metal cleaning

operations at Line 3. Waste sludge from the metal cleaning bath was disposed of at the former Blue Sludge Lagoon at the Inert Disposal Area (IDA) (IAAP-020) from 1979-1980. The Blue Sludge material was moved into Trench 6 at the IDA in January 1997. Prior to having the Line 3 Treatment Facility, untreated metal cleaning effluent was discharged to the ditches at Lines 3

and 800.

|

|

|