Orion Crew Exploration Vehicle

The US Orion spacecraft is scheduled to conduct its first unmanned flight to the Moon aboard the Space Launch System (SLS) giant rocket in the Artemis I program in February 2022, NASA said on 23 October 2021. The US space agency announced that US Artemis engineers had completed the stacking process of putting the Orion spacecraft on top of the SLS rocket at Kennedy Space Center for the Artemis I uncrewed mission around the Moon.

The Orion spacecraft was to venture thousands of miles beyond the moon during Exploration Mission-1, its first mission atop NASA's Space Launch System rocket. For the spacecraft’s first mission on the SLS rocket, ESA (European Space Agency) provided Orion’s service module, which powers, propels, cools and provides consumables like air and water in space. Results from ESA's service module design review, which began this month, would be assessed and incorporated into Orion development and integration plans later this summer. Systems unique to the first crewed flight would be addressed at a review in the fall of 2017.

In 05 December 2014 the successful first deep-space flight of NASA’s Orion on Exploration Flight Test-1 took the uncrewed spacecraft 3,600 miles into space and safely returned it to Earth. The 2014 flight was a big step on NASA’s journey to Mars, providing insights engineers have used to inform how they design, develop and build Orion that would help astronauts pioneer deep space destinations. Teams learned as much about what it takes to build and process Orion as they did about successfully flying it in space, and the flight test yielded more than 500 gigabytes of data to prove that the spacecraft’s many systems and subsystems performed as expected.

After NASA returned the spacecraft back to Kennedy Space Center, Orion’s flown heat shield was shipped to NASA’s Marshall Space Flight Center in Huntsville, Alabama, where its outer layer was removed for analysis before then being sent to the agency’s Langley Research Center in Hampton, Virginia. The heat shield protected the Orion spacecraft during its 4,000 degree reentry. At Langley, teams have fitted it to a test article and are preparing for a slate of tests in Langley’s Hydro Impact Basin that would evaluate how it fares in different potential splashdown scenarios. Overall, engineers developing Orion’s thermal protection system have been refining the spacecraft’s heat shield design and manufacturing process.

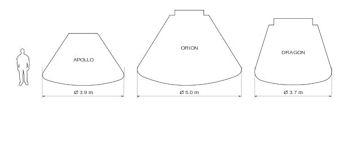

On 31 August 2006 NASA selected Lockheed Martin Corp., based in Bethesda, Md., as the prime contractor to design, develop, and build Orion, America's spacecraft for a new generation of explorers. Orion would be capable of transporting four crewmembers for lunar missions and later supporting crew transfers for Mars missions. Orion could also carry up to six crew members to and from the International Space Station.

The first Orion launch with humans onboard was planned for no later than 2014, and for a human moon landing no later than 2020. Orion would form a key element of extending a sustained human presence beyond low-Earth orbit to advance commerce, science and national leadership. The contract with Lockheed Martin was the conclusion of a two-phase selection process. NASA began working with the two contractor teams, Northrop Grumman/Boeing and Lockheed Martin, in July 2005 to perform concept refinement, trade studies, analysis of requirements and preliminary design options. Lockheed Martin would be responsible for the design, development, testing, and evaluation (DDT&E) of the new spacecraft.

Manufacturing and integration of the vehicle components would take place at contractor facilities across the country. Lockheed Martin would perform the majority of the Orion vehicle engineering work at NASA's Johnson Space Center, Houston, and complete final assembly of the vehicle at the Kennedy Space Center, FL. All 10 NASA centers would provide technical and engineering support to the Orion project.

The contract was structured into separate schedules for DDT&E with options for production of additional spacecraft and sustaining engineering. During DDT&E, NASA would use an end-item cost-plus-award-fee incentive contract. This makes the award fee subject to final determination after the contractor has demonstrated that it meets the technical, cost, and schedule requirements of the contract.

DDT&E work was estimated to occur from Sept. 8, 2006, through Sept. 7, 2013. The estimated value was $3.9 billion. Production and sustaining engineering activities are contract options that would allow NASA to obtain additional vehicles as needed. Delivery orders over and above those in the DDT&E portion would specify the number of spacecraft to be produced and the schedule on which they should be delivered. Post-development spacecraft delivery orders may begin as early as Sept. 8, 2009, through Sept. 7, 2019, if all options are exercised. The estimated value of these orders was negotiated based on future manifest requirements and knowledge gained through the DDT&E process and was estimated not to exceed $3.5 billion. Sustaining engineering work would be assigned through task orders. The work was expected to occur from Sept. 8, 2009, through Sept. 7, 2019, with an estimated value of $750 million, if all options are exercised.

The Orion crew exploration vehicle would be launched into Earth’s orbit by the Ares I crew launch vehicle. The Ares I first stage is a five-segment, reusable solid rocket and an upper stage powered by a J–2X engine. To maximize crew safety, Orion has incorporated a launch abort system to carry the crew safely away from possible life-threatening scenarios.

For missions to the moon, Orion would dock with Altair and an Earth departure stage in low Earth orbit. The Earth departure stage would propel Orion and Altair to the moon. Once they have reached the moon’s orbit, astronauts would use Altair to travel to the moon’s surface. Orion would stay in lunar orbit up to 210 days, awaiting return of the crew. After a stay on the lunar surface, the crew would return to the orbiting Orion using Altair as its ascent vehicle. Once the crew has reunited with Orion and Altair has been released, the service module main engine would provide the power for Orion to break out of lunar orbit and return to Earth.

As of 2010 the first fully functional ship was to be ready by 2012, and in September 2010, the Orion development company, Lockheed Martin, began developing full-size test prototypes that would be used for various tests. The assembly is expected to be completed by December 2010. In addition, Lockheed Martin experts were developing a plan for Orion’s manned mission to the asteroid. Since the ship was originally created for flights to the Moon, which take relatively little time, it would be necessary to modernize it to prepare Orion for long-distance space travel - in particular, to increase the area of usable space. Now the company is considering the option of combining the two Orions or connecting the ship with a larger residential module. It is planned that the ship would go to the asteroid with two astronauts on board.

The "Constellation" scenario assumed that new launch vehicles of the "Ares" series would be launched into the "Orions" orbit, but it was also decided to abandon their creation. Specialists at Lockheed Martin have stated that the spacecraft they are developing can be easily converted so that it would be compatible with existing heavy launch vehicles, such as Delta 4 or Atlas 5.

The White House decided to abandon the development of the program "Constellation", the ultimate goal of which was a flight to the Moon, in February 2010. Nevertheless, Lockheed Martin, which was one of the main contractors for NASA, continued to build the ship, regardless of the agency. However, the White House’s proposal for a complete reorientation of the US space strategy was not approved by both chambers of Congress, so that the final work plan for NASA would become clear later.